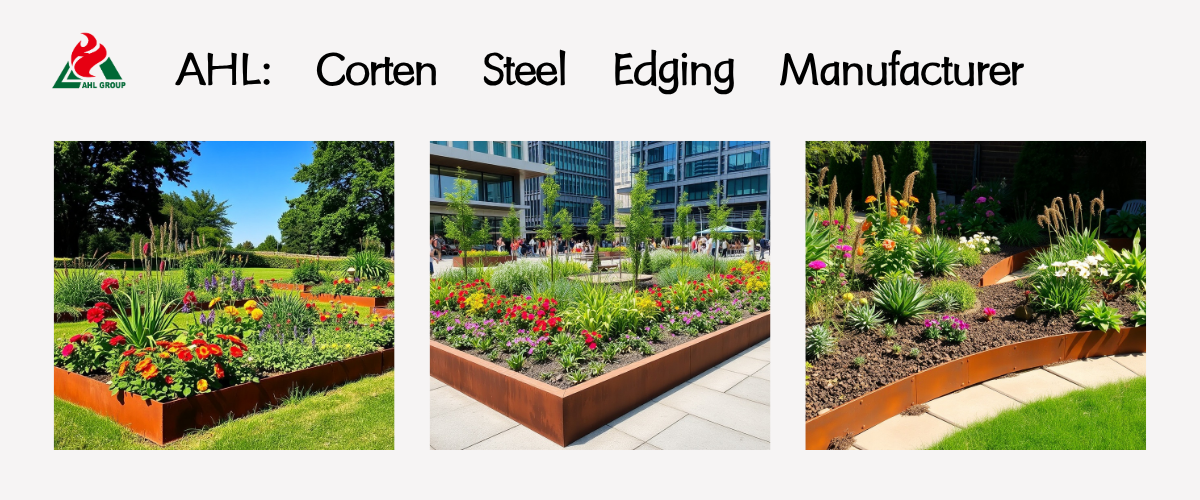

Corten steel edging serves as a durable cornerstone in modern landscape design. Their striking patina and decades-long lifespan make them an exceptional alternative to brittle plastics or reactive aluminum. However, the performance and ultimate value of weathering steel edging hinge entirely on one critical factor: Who is the manufacturer?

For landscape architects, commercial contractors, and discerning property owners, selecting a specialized manufacturer like AHL Group means more than acquiring a product—it guarantees quality assurance, technical support, and significant long-term value. This guide details the seven core advantages of sourcing weathering steel directly from the source.

For landscape architects, commercial contractors, and discerning property owners, selecting a specialized manufacturer like AHL Group means more than acquiring a product—it guarantees quality assurance, technical support, and significant long-term value. This guide details the seven core advantages of sourcing weathering steel directly from the source.

The Importance of Selecting Corten Steel Edging Suppliers

When procuring any specialized landscape material, your focus should shift from price alone to the overall value of the project.

Beyond Price: Understanding the Value Essence of Landscape Materials

The cost of Corten edging extends beyond the material itself, encompassing alloy quality, manufacturing precision, and supplier reliability. Manufacturers offering end-to-end control ensure the materials you receive deliver consistent performance throughout their intended lifespan.

Risks of Using Uncertified Suppliers

Uncertified suppliers or distributors often source materials with inconsistent alloy compositions, potentially leading to uneven patina development or structural failure. Once issues arise, tracing responsibility becomes extremely difficult, ultimately triggering costly project delays and material waste.

Benefit 1: Material Quality and Authenticity Assurance

The core benefit of partnering with manufacturers like AHL Group is the assurance of certified materials.

Certified ASTM A588 Weathering Steel

The term “weathering steel” is often used loosely. Manufacturers provide irrefutable assurance that the material is genuine ASTM A588 (or A606-4) weathering steel. This certification guarantees the alloy contains the copper, nickel, and chromium elements essential for forming the protective, stable rust layer—the core characteristic of this material.

Consistency in Thickness, Specifications, and Structural Integrity

We enforce strict control over material specifications. Whether you require flexible 1.5mm sheets for gentle curves or heavy-duty 3.0mm plates for rigid structural borders, manufacturers guarantee complete dimensional consistency across every sheet. This ensures uniform structural integrity and eliminates deformation risks.

Benefit 2: Direct Cost Savings and Competitive Pricing

Choosing the manufacturer eliminates unnecessary financial intermediaries, delivering exceptional value.

Eliminate Middleman Markups

Markups occur whenever materials pass through distributors, retailers, or third-party suppliers. By sourcing directly from AHL Group, you bypass these unnecessary costs. This results in direct cost savings, particularly advantageous for large-scale commercial landscaping projects.

Benefit from Volume Discounts and Bulk Purchase Pricing

Manufacturers operate systems designed for high-volume production. Clients undertaking large-scale projects—such as municipal parks or major residential developments—gain access to significant volume discounts and quantity-based pricing unavailable through standard retail channels.

Benefit 3: Custom Manufacturing and Design Flexibility

Manufacturers bring your design concepts to life through precision engineering.

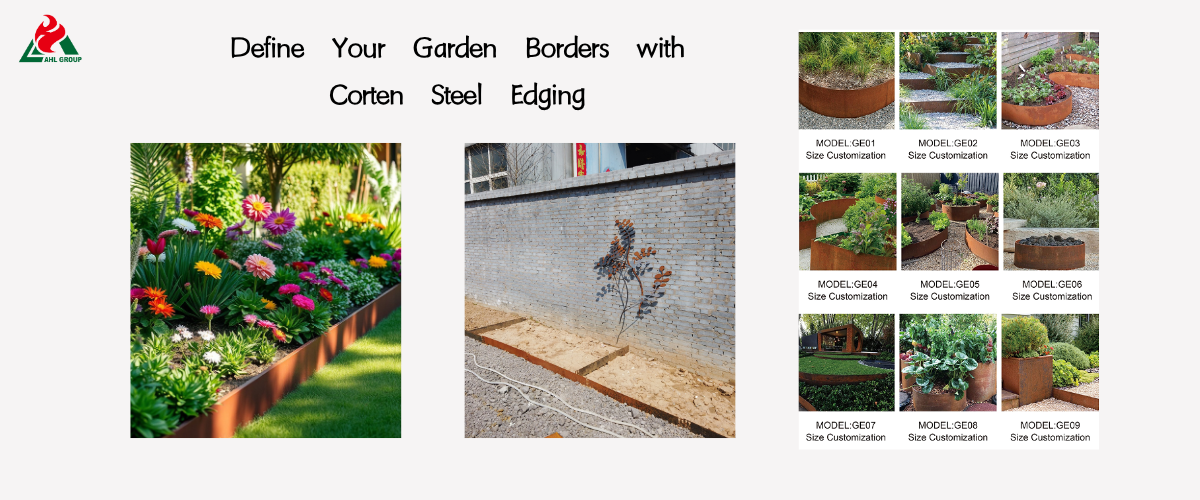

Height, Length, and Surface Finishes Tailored to Your Specifications

Your landscape design may require non-standard dimensions—such as 15cm-high borders for deep root isolation or specific 2-meter lengths to minimize seams. AHL Group offers custom Corten steel landscape border fabrication services, supporting precise height specifications, special folds, and custom lengths to minimize on-site cutting and material waste.

Crafting Unique Corners, Curves, and Custom Shapes

Precision designs involving sharp curves, acute angles, or intricate patterns demand specialized workshop capabilities. We utilize industrial-grade bending machines and precision laser cutters to create flawless, custom-shaped weathering steel elements and corners, ensuring structural integrity and seamless integration.

Benefit 4: Expert Technical Support and Guidance

Direct procurement grants you access to the collective expertise of our product design and manufacturing teams.

Professional Installation Advice

Installing weathering steel requires specific technical skills, particularly when managing rust flow or connecting long sections. AHL Group's technical support team provides precise guidance tailored to your soil conditions, including optimal foundation solutions, expansion joint management strategies, and best practices for securing Corten steel edging and corners.

Complex Project Specification Assistance

Architects facing high wind load requirements or unique drainage challenges require detailed material specifications and engineering data. We provide AHL Group's weathering steel technical data sheets and offer expert advice on plate thicknesses and installation methods compliant with stringent building codes.

Benefit 5: Stable Supply and Reliable Delivery Times

Manufacturers control the entire process, delivering stability that distributors cannot guarantee.

Direct Production Planning Control

We independently manage material inventory, cutting, forming, and surface treatment. This direct oversight enables us to provide reliable delivery cycles and prioritize your order scheduling—critical for meeting tight construction deadlines.

Avoiding Project Delays from Supply Chain Issues

Relying on imported or multi-tiered materials can lead to project stalls when supply chains are disrupted. As a specialized Corten steel manufacturer, we maintain substantial plate inventory, significantly reducing the risk of unexpected material shortages and ensuring your landscape projects proceed as planned.

Benefit 6: Comprehensive Product Warranty and Support

Manufacturers assume direct responsibility for their products.

Direct Accountability for Product Performance

Should issues arise—such as substandard weld quality or incorrect specification delivery—you can engage directly with the product manufacturer. AHL Group offers a comprehensive Corten metal edging strip warranty, providing peace of mind and ensuring swift, hassle-free solutions—a stark contrast to dealing through third-party retailers.

Effortless Resolution for All Issues

Even in rare instances of quality deviation, our direct accountability chain ensures swift replacements or corrections, minimizing downtime and safeguarding your project's reputation.

Benefit 7: Complete Component System Support

Achieving professional-grade results requires more than just the edge trim itself.

Matching Stakes, Connectors, and Hardware

Professional manufacturers provide complete weathering steel edge trim systems. This means all posts, connecting plates, and joining hardware are made from the same ASTM A588 alloy material as the edge trim. This is crucial for ensuring all components develop a uniform rust patina.

Ensuring a Professional, Coordinated Appearance

Using the complete, coordinated system provided by AHL Group ensures the finished product has no visual aesthetic discrepancies or structural weak points, presenting the distinctive professional, unified appearance characteristic of weathering steel.

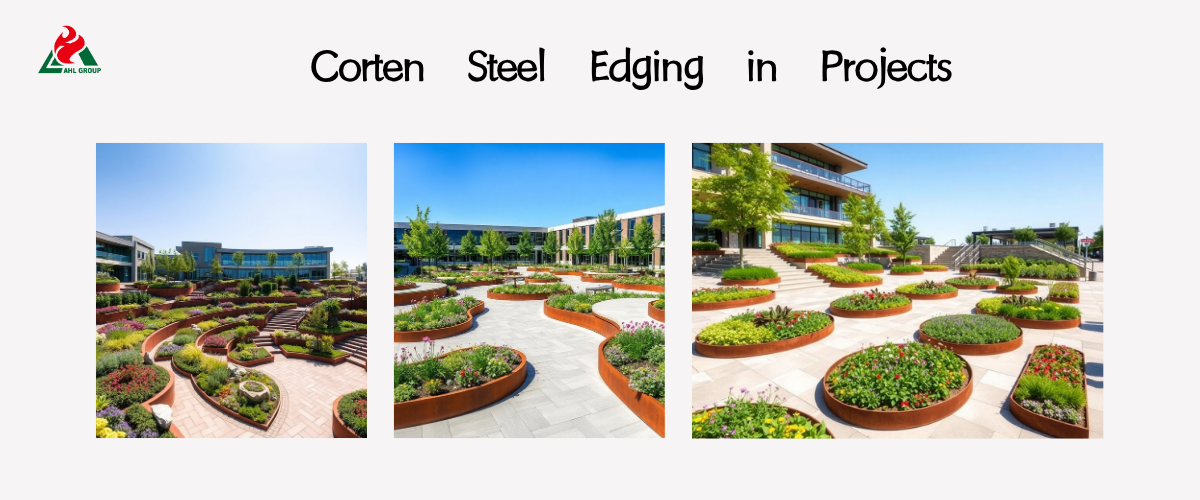

Case Study: Direct Manufacturing Reshapes Project

Challenge: Complex Commercial Landscape

A commercial client recently required 800 meters of garden edging for a multi-level plaza project featuring multiple small-radius curves and mandatory concealed fixing points. Initial distributor quotes were prohibitively expensive and failed to guarantee the required 4mm structural thickness for retaining components.

Solution: Custom Edge Components

AHL Group intervened by directly supplying the required 4mm-thick weathering steel. Using specialized equipment, we prefabricated compact curves and corner components in-house, delivering ready-to-install finished sections.

Outcome: Flawless Installation Within Budget

By eliminating intermediaries and utilizing prefabricated components, the client reduced installation time by 30% while achieving perfect structural alignment. Direct collaboration with AHL Group ensured the project was completed on schedule, within budget, and with impeccable quality.

Conclusion: Investment Value, Peace of Mind

The answer regarding material sourcing channels is clear: choose the manufacturer directly. While manufacturers' listed prices may sometimes appear comparable to distributors', the long-term cost-effectiveness and value delivered through their quality assurance, custom fabrication, and direct technical support are unmatched. Selecting AHL Group's Corten steel edging not only invests in your project's future quality but also means gaining absolute peace of mind.