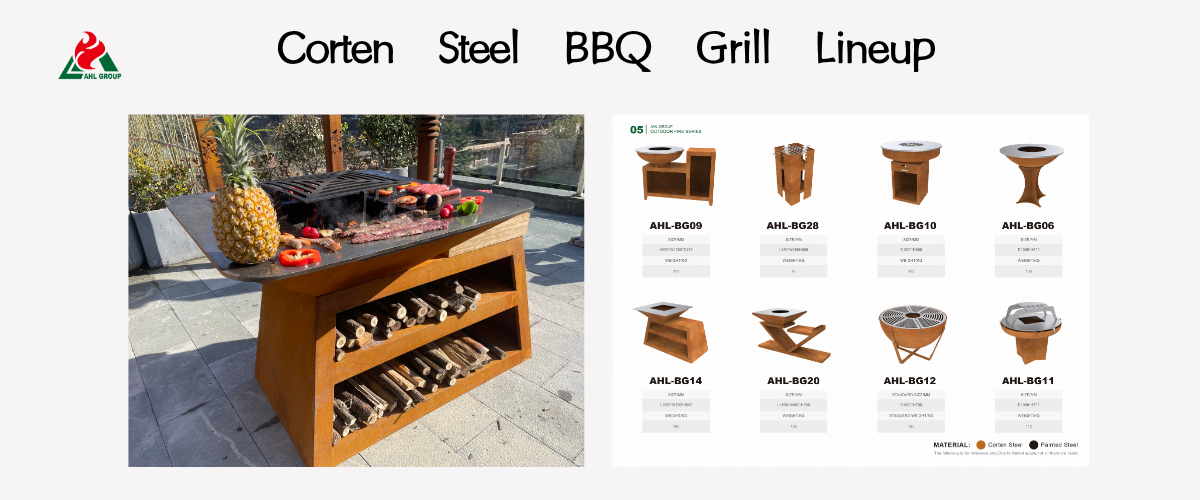

As the proud owner of an AHL Corten steel grill, you have invested in unparalleled durability and timeless artistic design. The captivating rust patina forming on the surface of this weathering steel grill is engineered to withstand natural erosion. However, each winter brings a critical maintenance decision. This guide, meticulously compiled by the AHL Group engineering team, addresses the most common winter challenges for your Corten grill: protecting the high-performance built-in gas system, burners, and cooking surfaces from moisture, freezing temperatures, and corrosion during extended periods of inactivity. Ensure your grilling equipment is ready for immediate use when spring arrives.

The Winter Dilemma of Corten Grill Owners

Corten steel—also known as weathering steel—is renowned for its corrosion resistance in harsh outdoor environments, making it an ideal material for permanent outdoor structures like BBQ grills. Unlike ordinary painted steel, which can severely flake and rust during winter, Corten steel forms a stable rust layer that provides natural protection. However, owning a Corten grill—especially high-end models with intricate internal components like burners, ignition systems, and electronics—presents a unique winter dilemma: How much protection is truly sufficient?

Balancing Convenience and Protection

The inherent durability of weathering steel may suggest it requires no protection. The metal body design allows year-round outdoor placement. However, the outdoor grill's sensitive internal components—infrared burners, gas connections, grease collection systems, and electronic igniters—remain vulnerable to damage from prolonged exposure to moisture, freeze-thaw cycles, and debris. Therefore, winter maintenance strategies must balance the minimal requirements of the weathering steel exterior with the maximum needs of the internal mechanical components.

Manufacturer Recommendations

AHL Group emphasizes: While the weathering steel shell withstands any climate flawlessly, protecting functionality requires proactive measures. Our core recommendations focus on cleaning and protection. Failure to clean the grill promptly and shield internal systems may cause igniter jams, burner blockages, and accelerate corrosion of non-weathering steel components within the barbecue grill cavity (such as stainless steel parts).

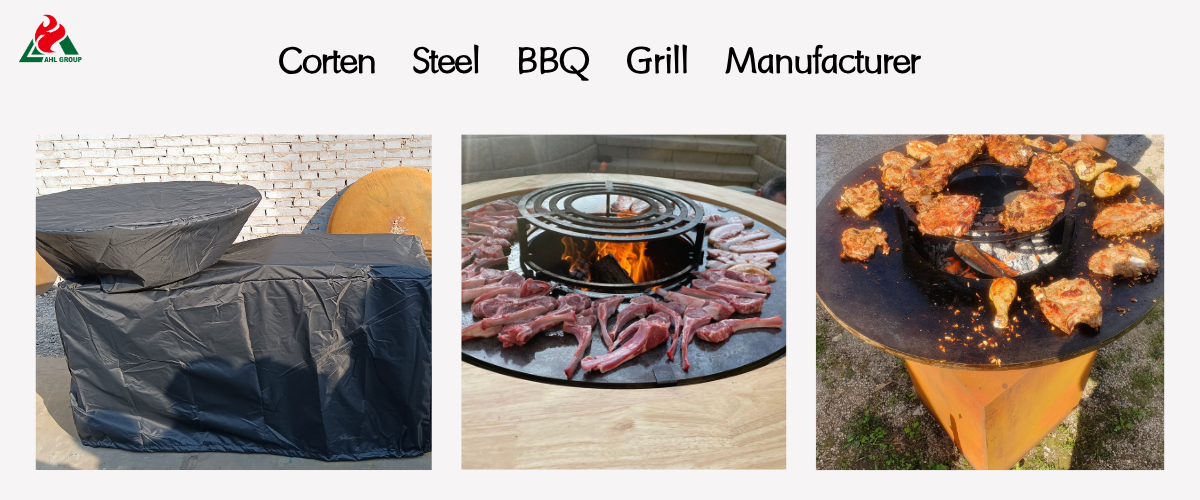

The Necessity of Using Protective Covers

The most convenient and effective measure against winter weathering is the use of high-quality breathable covers. Their purpose is not to prevent the natural patina of weathering steel, but to shield the grill's internal components from external threats.

Preventing Water Accumulation and Freezing

Protective covers effectively shield against heavy snowfall and prolonged rainfall. While weathering steel itself remains unaffected, persistent water pooling near grates or burner ports can cause unnecessary corrosion on stainless steel grates and nozzles. Crucially, a quality cover prevents moisture from freezing and expanding in sensitive areas, thereby avoiding stress on seals and connections. AHL Group recommends using specially designed covers to prevent water retention.

Keep Debris Out of the Burner and Grate

During high winds and storms, the cover prevents leaves, pine needles, dust, and insects from entering the Charcoal grill cavity. These particles can clog gas ports, block drain holes, and attract pests that may chew wires and hoses when the grill is idle. Keeping the interior clean ensures faster, safer ignition when spring arrives.

Protect Against Winter Sun and Harsh Weather

Even in winter, UV rays and prolonged exposure to cold, dry winds can degrade the durability of plastic knobs, hoses, and seals. A cover effectively minimizes seal expansion and contraction caused by temperature fluctuations, reducing material fatigue and the risk of eventual cracking.

When Storage Might Be Necessary

While most weathering steel grills can remain on patios, certain conditions still require moving them indoors for enhanced protection.

Considerations for Severe Cold Climates

If you reside in areas with months of deep snow cover or where temperatures consistently drop below -10°C (or 14°F), store your Corten grill in a garage, shed, or basement. This is especially crucial if your grill features electronic touch panels or complex control systems, as these components are sensitive to extreme cold.

Protecting High-End Internal Components

For premium AHL Corten steel grills equipped with rotisserie motors, specialized infrared burners, or internal lighting systems, it is strongly advised to remove these components for indoor storage. Freezing moisture can damage small motors and electronic circuit boards, leading to costly repairs.

Long-Term Idle Period Management

If the grill is expected to remain unused for over six months, even temporary relocation to a climate-controlled environment is the optimal preventive measure. This effectively prevents rust spreading to patio surfaces, insect infestations, and dirt accumulation.

Proper Winterization Steps

Before storing your Corten outdoor grill for winter, follow this essential checklist.

Thorough End-of-Season Cleaning

This is the most critical step. Residual grease and food particles attract pests and accelerate corrosion of internal metal components.

► Burn-off Method: Set the grill to high heat and run it for 15 minutes to carbonize all food residue.

► Scrape grates: Scrub and clean the cooking grates thoroughly.

► Clean interior: Remove the grill and seasoning bars, then scrape clean the interior walls and drip pans.

► Dispose of grease: Empty and clean the grease trap or collection system. Never leave grease in the pan over winter.

Protect gas lines and electrical components

Safety First: Disconnect and secure fuel sources.

► Propane: Close the tank valve, disconnect the regulator, and store the tank upright in a well-ventilated area (never in basements or enclosed spaces).

► Natural Gas: Close the main shut-off valve and ensure all pipe connections are secure.

► Electrical: Unplug the power cord, remove batteries from the igniter, and store indoors.

Preparing Your BBQ Grill for Hibernation

Prevent rust on stainless steel or cast iron grill surfaces:

► Apply a thin layer of cooking oil (such as canola or vegetable oil) to the clean, dry grill.

► Wrap the grill in newspaper or plastic wrap, return it to the oven cavity, or store it in a cool, dry place. This protective layer ensures your BBQ grill is ready to use come spring.

Spring Reactivation Guide

As the weather warms up, a simple yet important routine will refresh your Corten steel barbecue grill, preparing it for the new cooking season.

Post-Winter Inspection Checklist

► Check for pests: Visually inspect the interior of the grill, especially the burner tubes and manifolds, for signs of insect or rodent nesting. Use a wire brush or compressed air to clear any obstructions.

► Connection Check: Reconnect gas lines or propane regulators, then test joints for leaks using a soapy water solution—bubbles indicate leaks.

► Weathering Layer Check: Inspect the weathering steel body for mineral deposits or severe salt buildup (especially near coastal areas or snow-melting sidewalks). Rinse with clean water if necessary.

Grill Ready to Cook

► Reassembly: Reinstall the cleaned grill and seasoning rod.

► Burn-off: Run all burners at maximum heat for 10-15 minutes to thoroughly remove dust, stored residues, and oils applied during dormancy.

► Ignition Test: Inspect the ignition system to ensure all burner ports produce a clear, even blue flame. A weak or yellow flame indicates the burner ports may still be partially blocked.

Conclusion: Experience the Joy of Grilling with Corten Steel Grills

Enjoy the unmatched enduring beauty and rugged durability of your AHL Corten steel BBQ grill, though its internal mechanical and electrical systems require minimal annual winterization. By thoroughly cleaning the grill, protecting delicate components with a high-quality cover, and following proper power-off procedures, you can ensure this core piece of weathering steel equipment maintains reliable, efficient cooking performance for decades to come. Never let neglect turn simple maintenance into a spring overhaul.