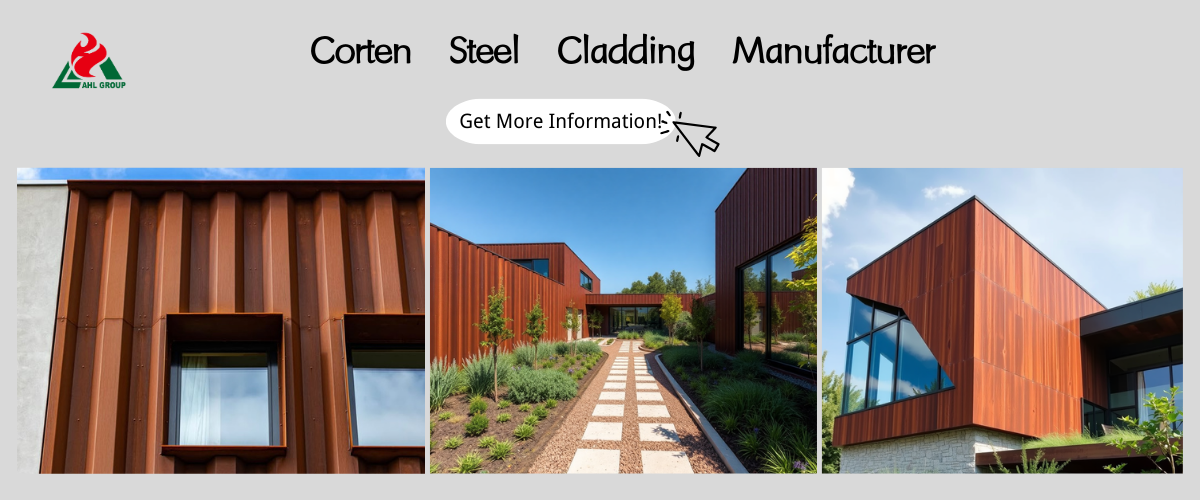

Corten steel cladding is a favoured material among architects and designers. Its rugged yet expressive appearance lends an organic and contemporary feel to every structure. However, achieving lasting visual appeal requires not only selecting the right material but also flawless installation. To ensure facades deliver a striking visual impact while maintaining structural integrity for decades, adhering to correct installation procedures is paramount.

This guide is a comprehensive overview of various installation methods, key steps, and best practices to guarantee the aesthetic and lasting quality of Corten steel cladding.

This guide is a comprehensive overview of various installation methods, key steps, and best practices to guarantee the aesthetic and lasting quality of Corten steel cladding.

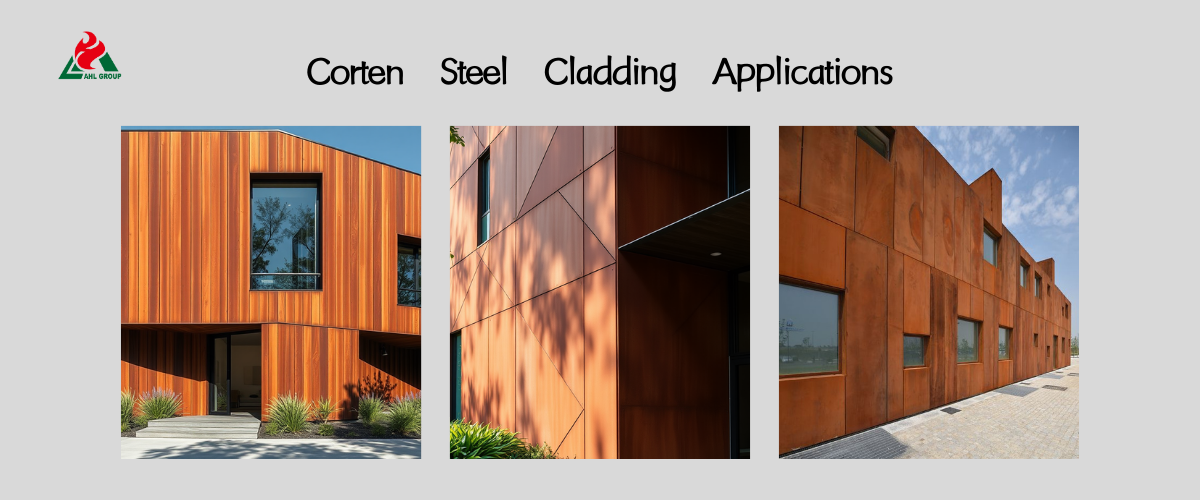

Understanding the Corten Steel Cladding System

Corten steel is not merely an ordinary steel; it is a unique alloy that naturally forms a protective rust layer under climatic conditions. This self-sealing process eliminates the need for painting, rendering the material a maintenance-free and exceptionally durable solution for building exteriors.

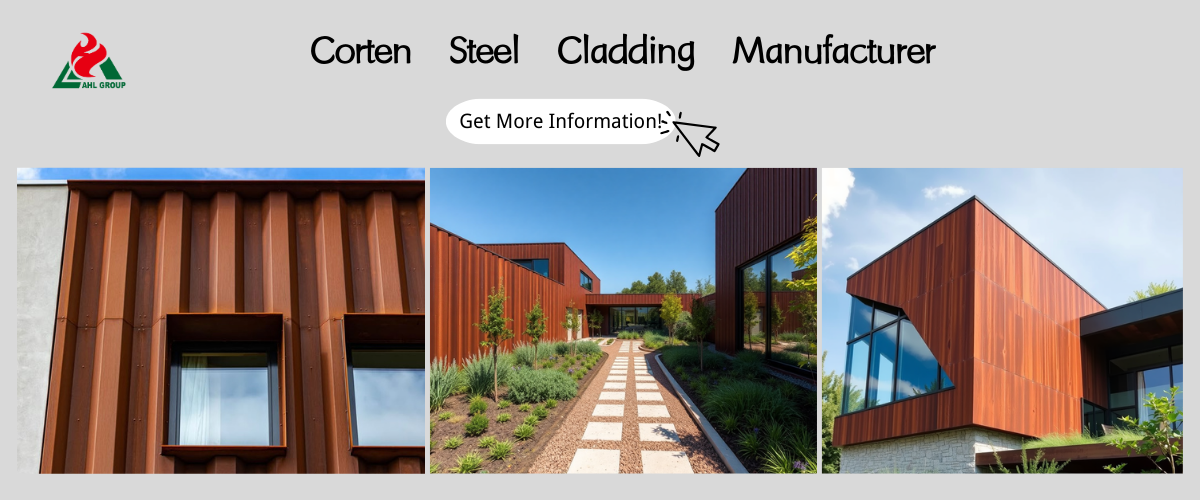

Advantages of Corten Steel in Architectural Facades

• Exceptional Durability: The protective rust coating makes Corten steel highly resistant to atmospheric corrosion, preventing the rusting of ordinary steel.

• Low Maintenance Costs: After the rust layer fully forms, the exterior requires virtually no maintenance, saving significant time and money over the lifetime of the building.

• Distinctive Aesthetics: The rusted surface appears in rich, varied hues, lending each Corten steel façade a unique appearance that increases in character with time.

• Sustainability: Corten steel is completely recyclable, which makes it an environmentally friendly choice for sustainable construction.

Critical Considerations Before Installing Corten Cladding

Before commencing installation of the Corten steel cladding, you must undertake thorough planning.

• Panel Weight: Corten steel panels are a heavy material. The building structure's architectural integrity must be assessed to ensure it can bear the weight of the entire cladding system.

• Thermal Expansion: Corten steel siding expands and contracts with temperature fluctuations. A properly designed fixing system is essential to accommodate this movement, avoiding the panels warping, twisting, or cracking.

• Rust Removal and Drainage: During the initial curing phase (which may last several months), corrosive particles may be released, contaminating surrounding materials such as concrete or stone. A permanent drainage solution is required, incorporating a gravel layer and drainage system.

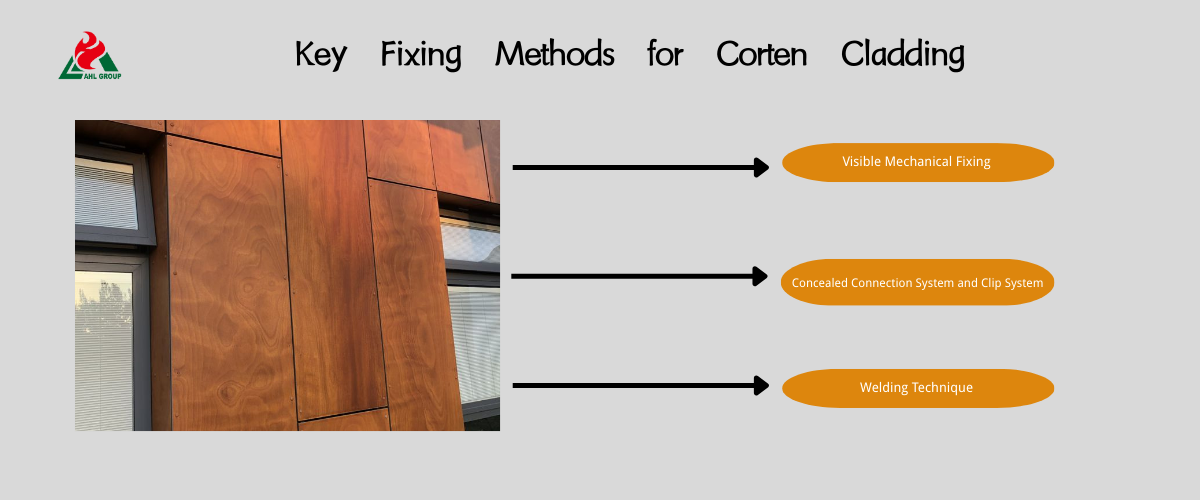

Key Fixing Methods for Corten Cladding

The method of fixing Cor-Ten steel sheets determines the final appearance and performance of the façade.

Visible Mechanical Fixing

Mechanical fixing is the most common and straightforward approach. These panels are fixed directly to the structure using screws or rivets. Fasteners should be made from corrosion-resistant materials, such as steel suitable for forming a rust patina or high-quality Corten steel capable of withstanding harsh weather conditions. This method is favoured for its simplicity and reliability. Exposed fasteners may even be utilised as design elements.

Concealed Connection System and Clip System

Concealed fixing systems are the optimal choice for achieving clean, seamless facades, as they completely hide fixing points. Panels are mounted onto hidden track systems using concealed fasteners. This installation method creates a seamless, smooth surface that highlights the natural beauty of the material. Although this technique involves a more complex installation process and demands greater precision, it provides the best adaptation to thermal expansion and contraction.

Welding Technique

This technique is used to create sophisticated, seamless appearances or sculptural facades without visible joints, requiring exceptional skill and precision. Corten steel siding panels are directly welded to the building's framework, producing a striking, seamless visual effect. However, the procedure is highly demanding, and replacement of individual panels proves challenging in the future.

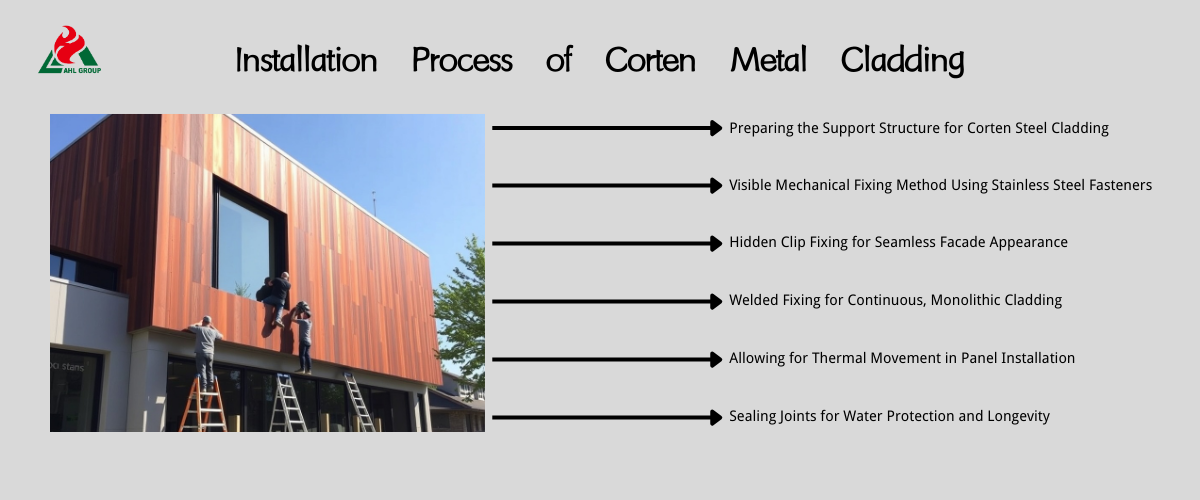

Installation Process of Corten Metal Cladding: A Step-by-Step Guide

Successful installation involves a combination of meticulous preparation and professional construction.

1. Preparation of Foundation Surface and Load-bearing Structure: The foundation surface of the building walls must be kept clean, dry, and level. Subsequently, the foundation load-bearing structure, composed of vertical and horizontal timber battens, must be securely fixed to the building structure. This structure will support the external wall panels and provide the necessary space for the rainwater drainage system.

2. Installation of the Primary Load-Bearing Framework: The framework, fabricated from corrosion-resistant materials such as stainless steel or aluminium, is installed at precise intervals according to the dimensions and weight of the panels. The use of unsuitable materials may lead to electrochemical corrosion, compromising the integrity of the entire system.

3. Installation of Corten Steel Panels: Cladding panels must be installed in a specific manner, proceeding from bottom to top. During construction, the installation of each Corten panel should be meticulously inspected to ensure a smooth and professional finish.

4. Attention to Thermal Expansion and Contraction: This critical step is frequently neglected. To prevent distortion, a uniform clearance of 1-3 mm must be maintained between panels. This space permits the expansion and contraction of the steel, thereby avoiding the generation of stresses within the system.

5. Sealing Joints and Gaps: Although weathering steel possesses inherent properties, joints between panels must also be sealed using compatible weathering-resistant sealant. This will protect against moisture ingress behind the cladding, thereby preventing structural damage.

Best Practices and Common Pitfalls to Avoid

• Rust Protection: To manage initial drainage, install drainage channels or lay a thin layer of gravel at the base of external walls. This simple measure prevents staining of pavements and foundations.

• Corrosion Conservation: To avoid electrochemical corrosion, employ only suitable connectors and supports. Inappropriate materials may cause accelerated deterioration of the entire external wall system.

Common Errors:

• Neglecting Thermal Movement: The most common error causing deformation and distortion.

• Using Inappropriate Fasteners: Fasteners unsuitable for Corten steel will rust rapidly, compromising the system's strength.

• Inadequately Prepared Substrates: Uneven or fragile substrates will cause damage to the whole façade with time.

Conclusion: Create a Visual Masterpiece with Corten Steel Cladding

For projects employing Corten metal cladding, it is strongly recommended to seek the assistance of experienced professionals to achieve a successful and enduring result. They can provide technical guidance and ensure each stage is executed correctly.