Corten steel fire pits have become iconic focal points in sophisticated outdoor living spaces. Homeowners and designers alike are drawn to this steel's rugged industrial aesthetic, particularly its deep orange-red patina. However, when extreme heat is a factor, a critical question arises: Does high temperature affect the patina of a Corten steel fire pit? If so, how exactly does it impact it?

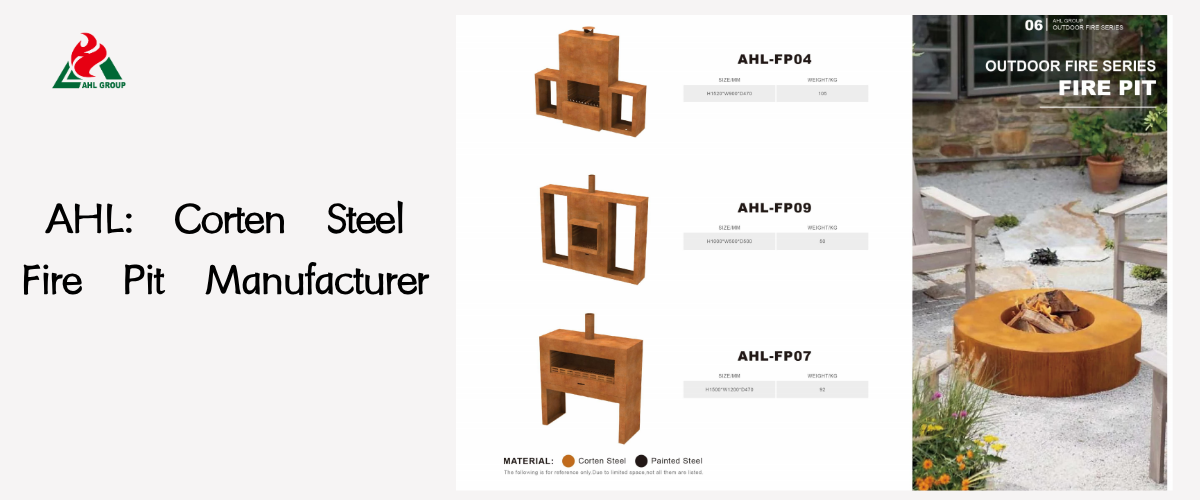

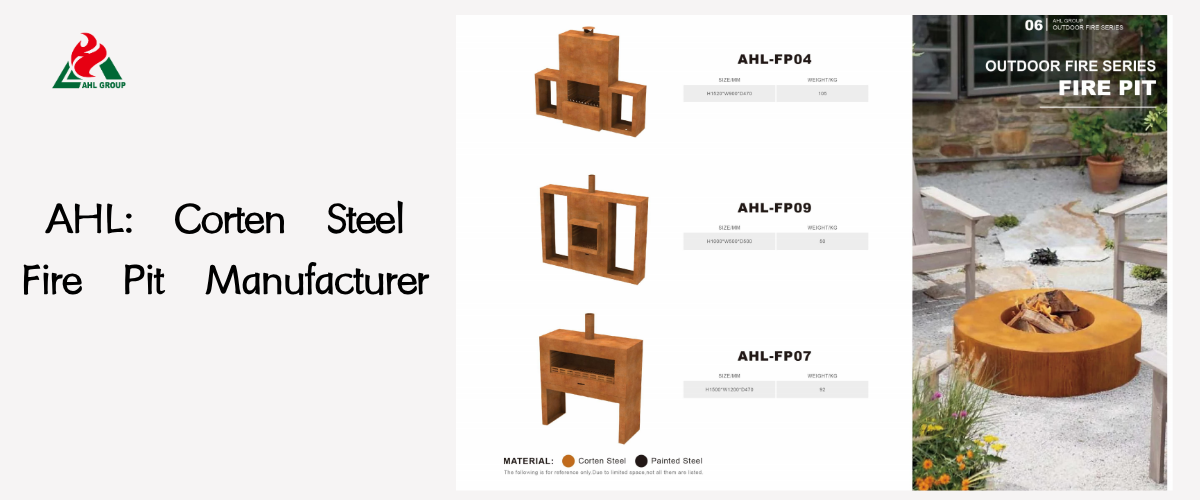

As a leading manufacturer of weathering steel products, AHL Group confirms: The unique thermal cycling process of fire pits not only preserves the rust patina but actively promotes its formation, accelerating the material's transformation into its ideal mature state. Understanding this process is key to both enjoying and maintaining your investment.

As a leading manufacturer of weathering steel products, AHL Group confirms: The unique thermal cycling process of fire pits not only preserves the rust patina but actively promotes its formation, accelerating the material's transformation into its ideal mature state. Understanding this process is key to both enjoying and maintaining your investment.

The Marriage of Fire and Steel

Corten steel (also known as weathering steel, conforming to ASTM A588 standard) forms a stable protective rust layer through specialized treatment. This rust layer prevents deep structural corrosion, granting it exceptional durability in outdoor environments.

Why Corten Steel and Fire Are a Perfect Match

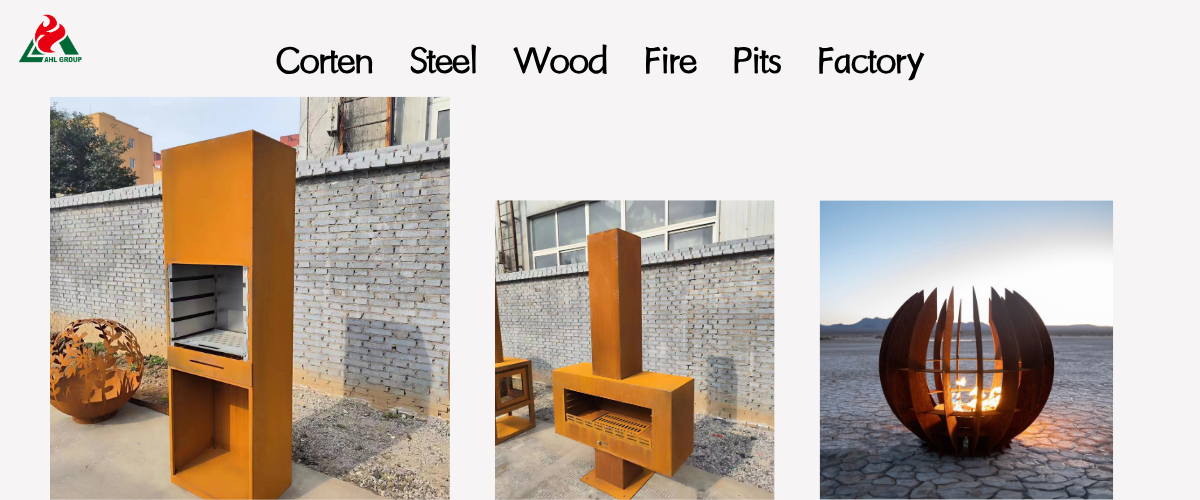

The inherent properties of Corten steel make it an ideal choice for high-temperature applications like fire pits and fireplaces.

• Corrosion Resistance: The protective rust layer effectively shields against the corrosive effects of rainwater and moisture, crucial for fire pits intermittently exposed to natural elements.

• Structural Integrity: Compared to most non-alloy steels, weathering steel maintains its strength better during repeated heating and cooling cycles, providing outstanding long-term durability for outdoor fire features. AHL Group ensures decades of service life through optimized fire pit thickness design.

• Aesthetic Symbiosis: The material's unique “natural aging” characteristics harmonize perfectly with the primal beauty of flames. Compared to materials that either age quickly or remain perpetually new, it offers an ideal blend of sustainability and aesthetic appeal.

Your Fire Pit, Alive with Life

A Corten steel durable fire pit is not a static object but a dynamic landscape element. Its surface undergoes continuous transformation through chemical reactions with moisture, oxygen, and the intense heat of flames. It is precisely this reaction that transforms a simple steel vessel into a uniquely textured work of art.

How Heat Intensifies and Accelerates the Patina

The heat generated by flames is crucial—it acts as a catalyst in the maturation of the rust layer, promoting the formation of deeper, richer colors.

Thermal Cycling: Heating and Cooling Effects

The continuous cycle of rapid heating (during combustion) and slow cooling (after extinguishing) is the primary driver accelerating rust layer formation.

• Drying Effect: When steel reaches high temperatures, residual moisture within the rust layer's microstructure rapidly evaporates. This process helps densify and consolidate amorphous, flaky iron oxide, ultimately forming an ideal, stable protective rust layer.

• Color Variation: Localized intense heat creates temperature gradients across the metal fire pit surface, producing stunning gradient hues. Areas directly exposed to flames develop deeper charcoal or purple-gray tones, while outer edges retain Corten steel's signature rich orange color. This heat-activated aging process allows fire pits to exhibit their signature characteristics faster than static Corten planters.

Why Fire Pits Develop Character Faster Than Other Weathering Steel Products

While Corten steel planters require 18 to 36 months to fully stabilize their rust patina, Corten fire pits typically achieve deep, stable coloring within just 3 to 6 months of regular use due to continuous thermal cycling. This accelerated characteristic is precisely its advantage, swiftly fulfilling users' desire for the classic, aged appearance of weathering steel.

The Chemistry of Heat-Activated Oxidation

When steel is heated, the oxidation rate accelerates. In an oxygen-rich environment, this heat enables alloying elements such as copper and chromium to migrate more effectively within the surface layer. This facilitates the formation of a tightly adherent oxide layer—the very layer that constitutes the hallmark of true weathering steel performance.

.png)

What to Expect as Your Fire Pit Ages

The oxidation process of your weathering steel fire pit is a journey filled with unique charm, progressing through several distinct stages.

Color Changes During Initial Use

When you first ignite your AHL fire pit, you will immediately observe significant changes:

• First Burn: High temperatures cause surface oxidation, transforming the bright exposed steel into a dull grayish-black hue.

• After Extinguishing: As the steel cools, moisture re-enters the surface, triggering rapid rusting. The color will shift to a vibrant, near-orange rust patina, potentially accompanied by slight flaking—this is entirely normal.

Long-Term Rust Evolution Across Seasons

Over time, the initial bright rust hue will gradually deepen. The most desirable and stable rust layer exhibits the following characteristics:

| Patina Stage |

Time Frame (Regular Use) | Appearance | Key Feature |

| Initial Patina |

0–3 Months | Bright, orange-yellow, with dust-like runoff. | Runoff is most significant. |

| Maturing Patina |

3–12 Months | Deepens to a rich, terracotta red. Runoff decreases significantly. | The protective layer begins to fully stabilize. |

| Stable Patina |

12+ Months | Dark, purplish-brown, highly textured, and matte finish. | Heat variation creates beautiful color banding. |

Crafting the Coveted “Patina Effect”

The ultimate goal of Corten steel outdoor fire pits is to achieve a “patina effect”—a rich tapestry of color shifts and textures that narrates the story of each blaze. Only through the passage of time, consistent use, and the combined forces of weather and heat can this effect be fully realized.

Enhancing Your Fire Pit's Natural Beauty

The best way to maintain a Corten metal fire pit is to work with its natural properties rather than force changes.

Techniques for Promoting Uniform Rust Formation

To rapidly develop a uniform rust layer across the entire bowl or main body of the fire pit:

• Controlled Moisture: During the initial weeks, spray the exterior of the fire pit with a hose every few days to promote necessary wet-dry cycles.

• Regular Use: The most effective accelerator is frequent use of the garden fire pit. Thermal cycling is the optimal catalyst.

• Avoid Covering Early: Though tempting, covering the fire pit prematurely traps moisture and delays the critical drying cycles needed for stable rust layer formation. Wait until the color deepens significantly before covering.

Reject Artificial Rusting Treatments

AHL Group strongly advises against using acidic solutions (such as vinegar or saltwater sprays) to “catalyze” rusting. While such methods may hasten rust formation, the resulting patina is often fragile and prone to flaking, offering far inferior protection compared to naturally developed, heat-accelerated rust layers. Trust the natural process—heat will complete the task.

Follow Nature's Course

Your fire pit is built to weather the elements. The low-maintenance nature of weathering steel means you need only ensure proper drainage (preventing water accumulation) to allow the natural environment and the heat from your fires to complete the aging process.

Frequently Asked Questions About Corten Fire Pits

Q: Can Corten Steel Fire Pits Overheat?

Under normal usage conditions (burning wood or gas), it is extremely unlikely for the high-quality weathering steel used by AHL Group to cause a fire pit to “overheat.” This steel possesses excellent high-temperature resistance. The only concern is thermal shock—never subject the steel to rapid cooling (such as throwing ice or large amounts of cold water into a fire pit), as this may cause material deformation or cracking.

Q: Does Wood vs. Gas Combustion Affect the Patina Differently?

Yes. Wood-burning Corten steel fire pits typically generate more intense localized heat sources and heavier soot, resulting in a deeper, richer, and faster-forming thermal patina, especially on the bottom and central areas. Gas Corten steel fire pits provide more uniform, cleaner heating across the surface, resulting in a more consistent oxidized layer with less pronounced deep charcoal tones.

Q: How Can I Clean Without Damaging the Thermally Oxidized Layer?

The cleaning process is simple and gentle:

• Remove Ash: Scoop out cooled ash after each use.

• Avoid harsh chemicals: Never use abrasive brushes, detergents, or chemical cleaners, as these will strip the protective rust layer.

• Rinsing (optional): If needed, simply rinse with water and wipe with a soft cloth to remove surface grime. The heat-formed rust layer is extremely durable and won't be easily damaged by gentle cleaning.

Conclusion: Elevate Your Outdoor Living Experience with Corten Steel Fire Pits

The heat generated by fire pits is not a threat to the material but an integral part of its nature. Thermal cycling serves as a natural and essential catalyst, helping weathering steel develop a deeper, denser, and more aesthetically pleasing protective patina.

Choose a Corten steel fire pit meticulously crafted by AHL Group to embrace the natural processes of weathering and combustion. You're not just purchasing outdoor equipment—you're investing in a low-maintenance, high-aesthetic landscape artwork. With each use, it will continue to evolve, revealing increasingly unique character. Experience the transformative power of fire and steel!