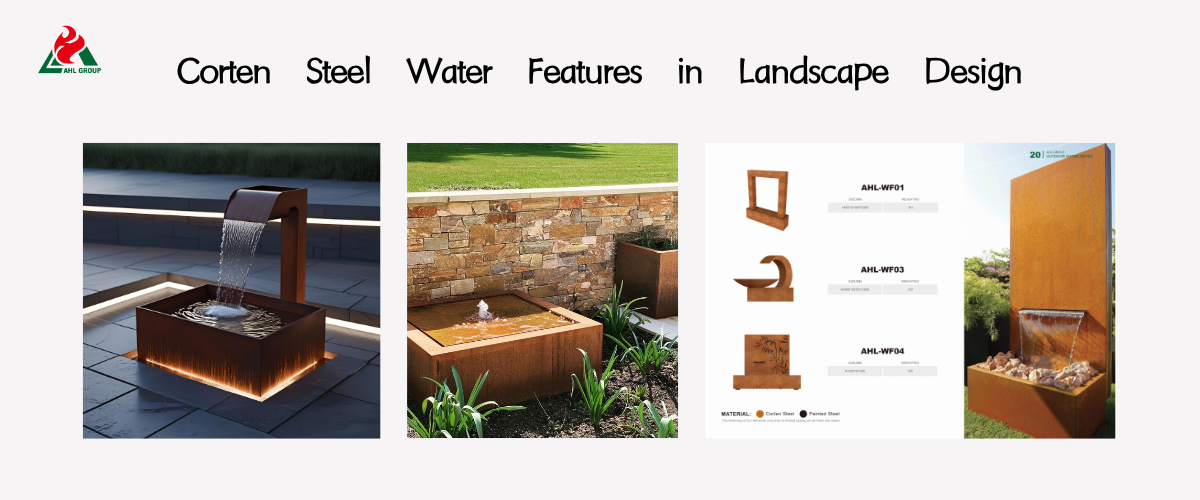

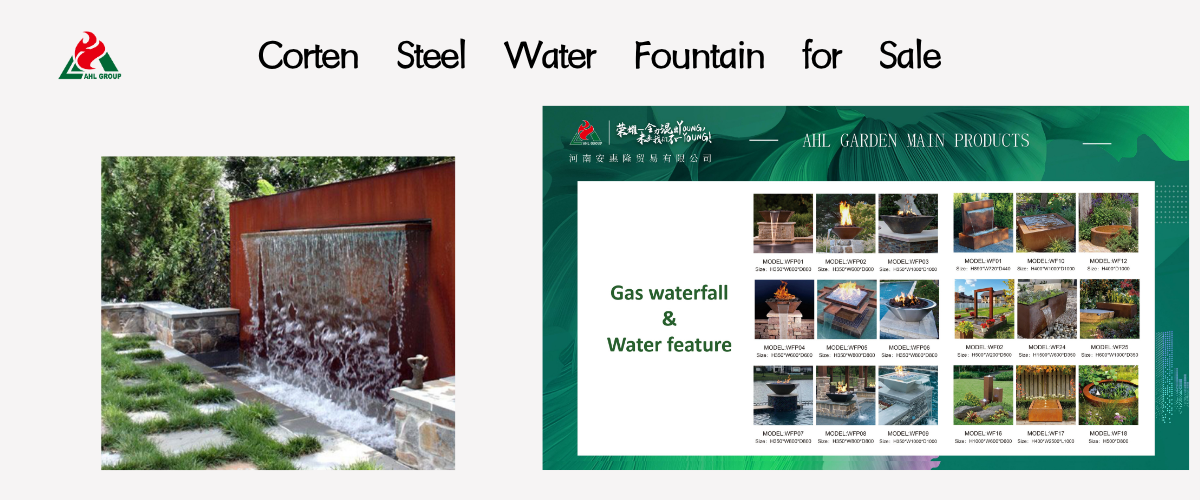

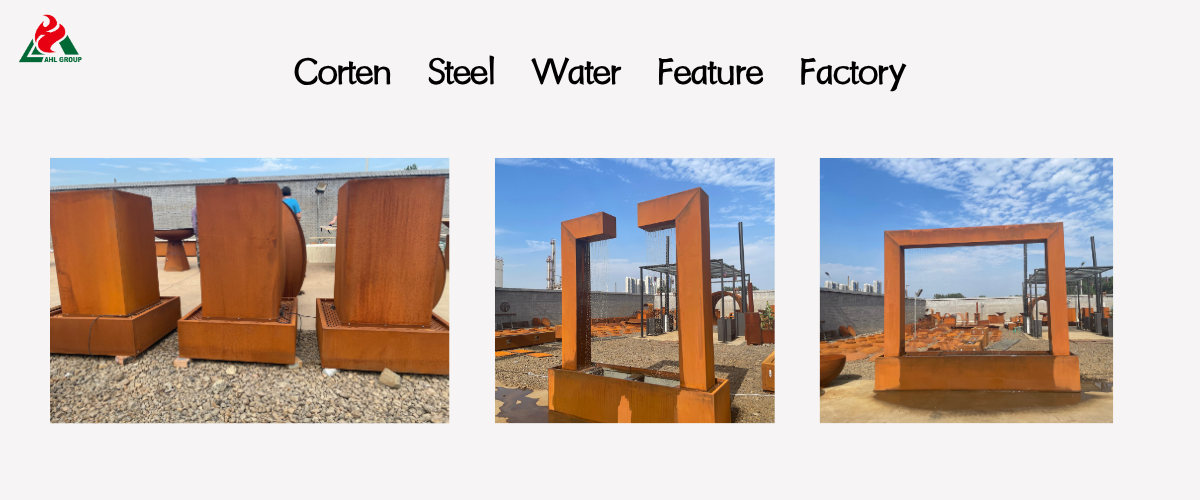

Corten steel captivates modern landscape designers, transforming ordinary outdoor spaces into sophisticated environments that rival art galleries. Whether as sculptural planters, striking retaining walls, or central elements in the construction of metal water features, its distinctive orange-brown hue seamlessly blends industrial texture with natural warmth. This material not only retains water but also imbues spaces with a unique character that grows more enchanting with time.

Yet, the very characteristic that makes weathering steel so prized—controlled corrosion—often presents a dilemma for owners and maintenance personnel. AHL Group's most frequent inquiries center on long-term care: Does this beautiful, evolving material require sealing? Before making decisions that could impact the longevity and aesthetics of water feature installations, understanding the science behind weathering steel is paramount.

Yet, the very characteristic that makes weathering steel so prized—controlled corrosion—often presents a dilemma for owners and maintenance personnel. AHL Group's most frequent inquiries center on long-term care: Does this beautiful, evolving material require sealing? Before making decisions that could impact the longevity and aesthetics of water feature installations, understanding the science behind weathering steel is paramount.

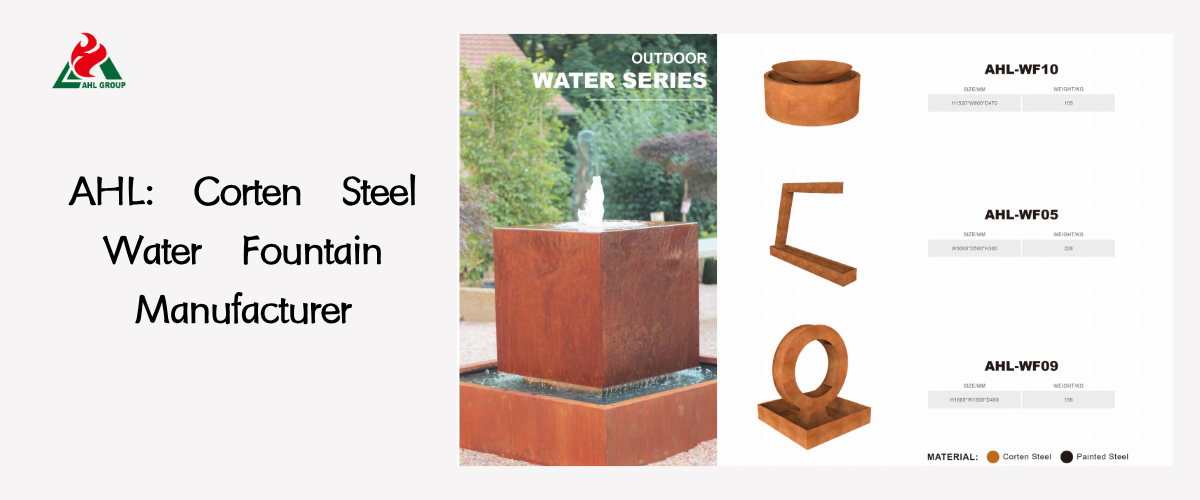

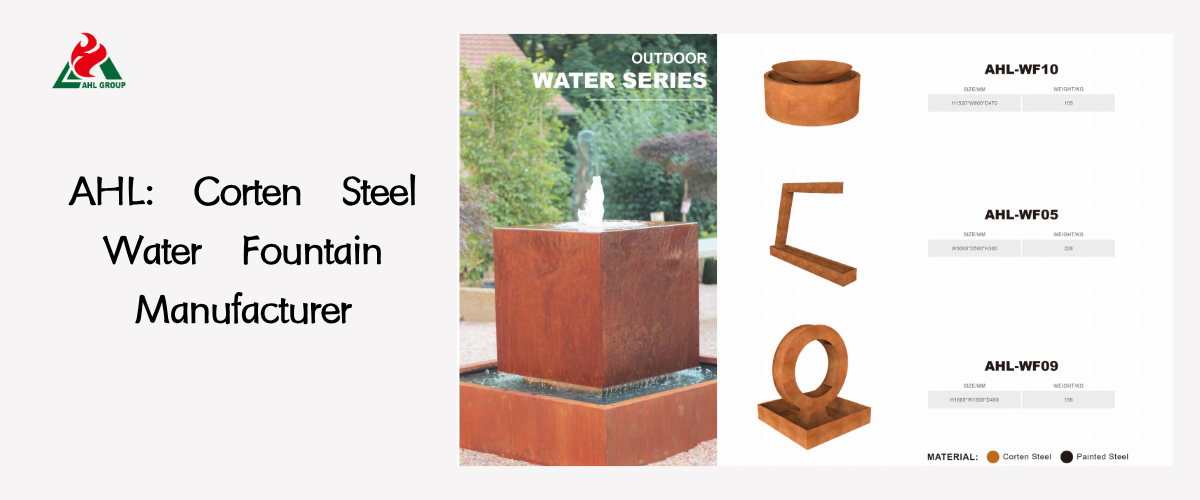

Introduction to Corten Steel in Water Features

Weathering steel (scientifically known as Corten steel, conforming to ASTM A588 or A242 standards) has become a staple in modern landscape architecture. Its deep reddish-brown rust patina and exceptional durability make it an ideal material for garden planters, architectural cladding, and increasingly popular Corten steel water features.

Unique Properties of Corten Steel

The core advantage of weathering steel lies in its self-protective nature. Unlike ordinary carbon steel, it contains alloying elements such as copper, chromium, and nickel. In environments subject to alternating moisture and dryness, these elements promote the formation of a dense, strongly adherent, and structurally stable rust layer—the renowned protective patina. This layer acts as a barrier, effectively delaying further corrosion and significantly extending the material's service life.

Water Interaction with Weathering Steel Rust Layers

In water feature applications, weathering steel undergoes continuous exposure to moisture, which is critical to the rust layer formation process.

• Initial Stage (6–18 months): Unstable hydrated iron oxides form on the steel surface. This phase exhibits a vivid orange hue and represents a period of significant rust loss. This is a normal and necessary stage in the weathering steel lifecycle.

• Stabilization Stage (18–36 months): Through repeated wet-dry cycles, unstable oxides transform into a dense, stable structure. The color deepens to a rich dark brown or purplish red. Upon completion of this stage, the corrosion rate significantly decreases.

The Short Answer: No, Don't Seal Your Corten Water Feature

A core question property owners often face is: “Should I seal Corten steel water features to prevent rusting?” As a manufacturer, AHL Group unequivocally advises: No, sealing is generally not recommended, as it often compromises the material’s performance.

Sealing fundamentally interferes with the material’s core function and can cause far more serious problems than natural weathering.

Preserving the Self-Protection Mechanism

The design philosophy of weathering steel is precisely to “let it rust.” Sealants block the oxygen and moisture the steel needs to form its protective rust layer. Once the sealant layer is scratched or fails to bond, moisture becomes trapped beneath the coating. This trapped moisture, deprived of the necessary drying cycles, fosters destructive blistering corrosion—far more aggressive than the naturally formed stable rust layer. This phenomenon is known as undercoat corrosion.

Preserving Authentic Rustic Aesthetics

The primary reason designers specify weathering steel lies in its unique, matte, and naturally textured aesthetic qualities. Conventional transparent coatings or sealants typically create an unnatural wet appearance or high-gloss surface. This alters the material's original character, deviating from the desired industrial rustic style and instead producing a plastic or artificial surface effect.

Detailed Explanation: Why Sealing is Not Recommended

The decision not to seal your weathering steel fountain is primarily based on two key factors: the material's chemical properties and the practical feasibility of long-term maintenance. The following section will detail how coatings actively interfere with the protective process and why they introduce costly and unnecessary points of failure.

Chemical Incompatibility with Weathering Processes

The rust layer of weathering steel forms a dynamic microporous structure that breathes and self-repairs.

• Non-Breathable Coatings: Most sealants aim to block significant moisture but may lack the microporosity required for stable oxide layer formation. They impede the micro-gas exchange essential for the long-term integrity of the rust layer.

• Mineral and Salt Retention: In recirculating water fountains, evaporation leaves behind hard water minerals (scale) and water treatment chemicals (e.g., chlorine). If sealants contain pinholes or defects, these corrosive substances infiltrate and become trapped beneath the coating, significantly accelerating localized pitting corrosion.

Practical Maintenance Considerations

Sealed Corten water fountains are not maintenance-free; rather, they introduce a new task with high maintenance costs.

• Coating Lifespan: Sealants (whether polyurethane or acrylic) last only 1 to 3 years under continuous UV radiation and water immersion. Once the coating begins to deteriorate and peel, the process of removing residual coating and repairing underlying damage is far more complex and costly than directly maintaining exposed steel.

• Repair Difficulty: If corrosion occurs beneath the sealant layer, the entire coating must be completely removed (typically requiring sandblasting or strong chemical agents), followed by re-treatment of the steel surface before resealing. The labor costs for this process increase exponentially, far exceeding the maintenance approach of allowing the steel to weather naturally.

Long-Term Performance Impact

The structural lifespan of weathering steel is typically measured in decades—under appropriate environmental conditions, AHL Group guarantees the integrity of its weathering steel structures for over 40 years. Sealing treatments may actually compromise this durability by creating potential failure points. Unsealed weathering steel products, when properly designed and equipped with effective drainage systems, achieve the lowest total cost of ownership due to their inherently minimal maintenance requirements.

When Sealing Might Be Considered (And How to Do It Right)

Although sealants are strongly discouraged for outdoor applications, there are rare exceptions where sealing is necessary.

Special Exception: Indoor Water Feature Installations

Indoor environments typically lack the UV exposure and intense wet-dry cycles required outdoors to fully stabilize the rust patina. More critically, indoor water features must absolutely guarantee zero rust seepage to protect expensive indoor flooring and finishes. In this specific scenario, sealing may be a non-negotiable requirement.

Sealant Selection for Special Applications

If sealing weathering steel is unavoidable, select a high-penetration, matte acrylic or wax-based sealant specifically formulated for weathering steel.

• Avoid: Epoxy or standard polyurethane sealants, which are typically too thick and produce an undesirable high-gloss finish.

• Recommended: Film-forming, high-solids acrylic sealants that protect while maximizing the preservation of a matte appearance. Such sealants must possess UV resistance and waterproof properties.

Professional Application Requirements

Weathering steel seals must adhere to a strict preparation process:

• Complete Stabilization: Corten metal water feature must be fully stabilized and thoroughly dried before applying any sealant (ideally requiring 12-18 months of outdoor exposure).

• Cleanliness: Surfaces must be absolutely clean before application, with all dust, grease, and moisture thoroughly removed.

• Thin-Coat Application: Follow the sealant manufacturer's instructions, typically applying two to three extremely thin coats to ensure even coverage and adhesion, avoiding the formation of a thick, glossy film.

Expert Recommendations

When advancing Corten landscape water feature projects, the most effective long-term strategy lies in proactively making design choices and adhering to manufacturer guidelines, rather than attempting to seal surfaces as an afterthought. These recommendations ensure the structure's durability and aesthetic integrity.

Landscape Architect Recommendations

Leading landscape architects typically recommend design solutions over sealing treatments for runoff management:• Drainage Strategies: Position weathering steel water features on dark gravel bases, use dark paving materials, or incorporate integrated concealed collection basins to capture minimal runoff during the initial weathering phase.

• Pre-Weathering Treatment: Large-scale projects often utilize pre-weathered steel from manufacturers like AHL Group. This process accelerates rust layer formation before installation, significantly reducing on-site oxidation time.

Manufacturer Guidelines and Warranty Terms

As a premium weathering steel supplier, AHL Group adheres to industry best practices:

• Sealing Policy: All standard weathering steel water fountains are designed and sold unsealed to achieve intended durability.

• Warranty Limitations: Unauthorized application of sealants or coatings to weathering steel surfaces typically voids the long-term performance warranty covering natural weathering failure. Consult our technical team before making any surface modifications.

Frequently Asked Questions About Corten Water Fountains

Q: Can Any Varnish Be Used on Weathering Steel?

No. Ordinary oil-based or water-based varnishes are chemically incompatible with the microporous, continuously evolving rust layer on weathering steel surfaces. Such varnishes typically fail to adhere long-term, leading to blistering, peeling, and leaving behind residue that is extremely difficult to remove.

Q: What About Wax or Oil Treatments?

Natural treatments such as Brazilian palm wax or linseed oil can be used to deepen the color and provide mild stain resistance to the stable rust layer that forms on weathering steel. These treatments do not create a hard film, so they do not trap moisture or affect the steel's breathability. This is an acceptable method for enhancing color, producing a soft matte finish, but it requires regular reapplication.

Conclusion: Elevate Your Garden's Aesthetic with Corten Steel Water Features

The enduring beauty and structural integrity of Corten steel water bowls are intrinsically linked to their unsealed, naturally breathing protective rust patina. While sealing may be a necessary compromise in rare indoor or extreme environments, this practice typically does more harm than good for outdoor installations.

By selecting weathering steel professionally manufactured by AHL Group and integrating it with thoughtful landscape design, you will fully experience this unique material's low maintenance requirements and high aesthetic value. Your water feature will gracefully reveal the passage of time through its natural patina over the years.