As permanent architectural components, Corten steel landscape lighting is designed for minimal maintenance requirements. Unlike painted or powder-coated metals, the aesthetic appeal of weathering steel stems from a controlled oxidation process, eliminating the need for stripping, sanding, or repainting. However, “minimal” does not equate to “zero maintenance.” Establishing a simple routine maintenance plan is essential to ensure the longevity of electrical components and the structural integrity of the material. This AHL Group guide provides a comprehensive checklist for maintaining weathering steel lighting.

Understanding Corten Steel in Landscape Lighting

Maintenance of Corten steel lamps hinges on distinguishing decorative patina from functional integrity. While the outdoor lamp's rugged, aesthetically pleasing exterior serves as its protective layer, the internal precision electrical components require proactive upkeep.

Material Properties and Weathering Process

Weathering steel (ASTM A588), treated through specialized processes, develops a dense, stable rust protective layer that significantly delays deep corrosion. This self-healing barrier is exceptionally durable, offering high resistance to environmental stresses like UV radiation, rainfall, and thermal cycling. For the metal casing, maintenance primarily involves supporting this natural process.

Impact of Lighting Usage on Maintenance Requirements

Maintenance focus shifts from the metal body to internal electrical systems. Bulb heat, power cables, and internal humidity may pose challenges to seals and connection points. Additionally, light fixtures must maintain structural stability, particularly tall bollard lights or pathway lights subjected to foot traffic and wind forces.

Routine Maintenance Checklist

Daily upkeep should be simple, non-invasive, and performed annually or biannually. This checklist emphasizes proactive measures to ensure functional reliability and aesthetic consistency of Corten steel lights. It aims to protect critical electrical components from moisture and environmental corrosion while preserving the metal's distinctive protective patina.

Task 1: Surface and Rust Layer Maintenance

The core of routine maintenance lies in preserving the aesthetic continuity of the weathering process.

Natural Processes vs. Gentle Cleaning

In most cases, the best way to maintain the rust layer on weathering steel is to let it remain in its natural state. Wind and rain will naturally remove loose debris and dirt. However, if the installation becomes contaminated with mud, fertilizer, or pool chlorine water, follow these steps:

► Gentle Rinse: Use a low-pressure hose to rinse the installation.

► Gentle Brushing: Stubborn residues (such as scale or mineral deposits) can be addressed with a soft-bristled brush (non-metallic) and clean water.

► Avoid chemicals: Never use abrasive cleaners, acidic detergents, or solvents, as these strip the rust patina and restart aggressive corrosion cycles. AHL Group advises against sealants in outdoor environments, as they trap moisture and cause premature failure.

Task 2: Electrical System Maintenance

The lifespan of garden lighting depends on the health of their connections. Inspections should be conducted annually, ideally before the onset of heavy rain or snow seasons.

Bulb Replacement and Connection Inspection

► Inspect gaskets and seals: When replacing bulbs (always use recommended wattage/types, such as low-heat LEDs), check the integrity of all rubber gaskets and seals. These components prevent moisture ingress into the fixture, avoiding short circuits or internal corrosion.

► Check Wiring Connections: For low-voltage systems, inspect connection points between lamps and transformers. Ensure wires are securely fastened and that wire caps or connectors are fully waterproof and not submerged in standing water.

► Internal Debris Removal: Gently clean reflectors and lenses. Use canned compressed air to remove cobwebs or dust from inside the lamp housing.

Task 3: Structural Integrity Inspection

Ensure luminaires are stable, vertical, and securely anchored to prevent stress on electrical connections.

Inspect Brackets, Poles, and Foundations

► Tighten Brackets: For wall-mounted or pole-mounted lights, verify all screws and bolts are fully tightened. Vibration from wind or impact can cause fittings to loosen over time.

► Inspect Pile Foundations: For pathway lights, examine the foundation (concrete or ground piles) for signs of ground heave or displacement, which may cause the fixture to tilt. Re-secure any loose fixtures to prevent cable stress.

► Drainage Inspection: Ensure the area around the lamp base drains properly to avoid prolonged water immersion at the base, which may accelerate corrosion at the soil contact surface.

Special Considerations for Different Styles

Maintenance procedures should be adjusted based on the light's exposure level and functional characteristics.

Spiked Pole Lights vs. Wall-Mounted Lights

► Spiked Pole Lights: Susceptible to ground displacement. Inspect vertical alignment annually in spring and fall, repositioning as needed. Ensure cables are safely buried.

► Wall-Mounted Lamps: Focus on inspecting the seal between the mounting plate and building materials to prevent moisture penetration into the wall structure.

Low-Voltage Systems vs. Solar Systems

► Low-Voltage Systems: Inspect the main transformer output and ensure underground cable lines remain intact.

► Solar Systems: Small solar panels require regular cleaning (weekly/monthly) to maximize charging efficiency, especially in dusty or densely vegetated environments.

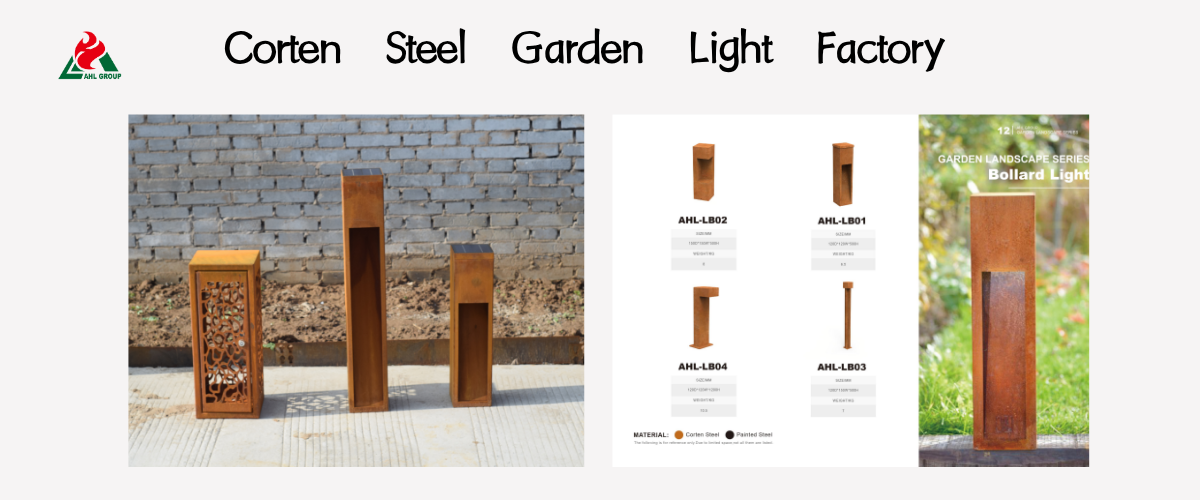

Laser-Cut Patterned Lamps

Often designed by AHL Group, these metal lights create unique visual effects but increase debris accumulation risk. Use a soft-bristle brush to regularly clean patterned surfaces, preventing material buildup that causes light leakage or moisture retention on the patina layer.

Advanced Maintenance Techniques

Although the self-protective properties of weathering steel minimize routine maintenance, certain environments or design elements—such as intricate laser-cut components—require more focused and proactive care. These advanced techniques extend beyond basic cleaning to address specific challenges like protecting delicate details, managing localized moisture, and preventing insect infestation, ensuring installations remain flawless and aesthetically pristine for decades.

Protecting Laser-Cut Details

Gently remove debris and insects from laser-cut patterns using non-abrasive tools like compressed air or a fine-bristle brush. This prevents organic matter from accelerating localized uneven corrosion and avoids pitting.

Drainage and Water Accumulation Management

Most fixtures feature drainage holes at the base or sides to expel condensation and moisture. Regularly inspect these openings for blockages caused by dirt or rust particles to prevent water accumulation inside electrical housings.

Preventing Insect Nests Inside Lights

Insects—particularly spiders and wasps—are often drawn to the enclosed, dark spaces of light fixtures, potentially causing blockages or damaging wiring. When inspecting bulbs, remove any insect nests and consider applying insect repellent around the fixture base (not on the weathering steel surface itself).

.png)

Professional vs. DIY Maintenance

The inherent durability of weathering steel means most tasks can be safely handled by property owners or landscape maintenance personnel.

Tasks You Can Safely Perform Yourself

► Surface rinsing and gentle cleaning (Task 1).

► Bulb replacement (Task 2).

► Structural tightening and fixture adjustment (Task 3).

► Cleaning solar panels and clearing drain holes.

When to Contact an Electrician or Professional

► Any issues involving the main power line or transformer.

► Persistent short circuits or flickering after replacing bulbs.

► Replacing underground low-voltage cables or performing major repairs on foundation brackets.

► Internal corrosion has exposed wires or damaged socket assemblies.

Conclusion: Illuminate Your Outdoor Space with Corten Steel Garden Lights

Engineered for enduring durability, Corten steel lighting represents the ultimate low-maintenance illumination solution. With just a few hours annually spent inspecting electrical connections and structural supports—while allowing the patina to perform its self-protective function—AHL Group's Corten steel lights will deliver decades of stunning illumination and architectural beauty to your space.