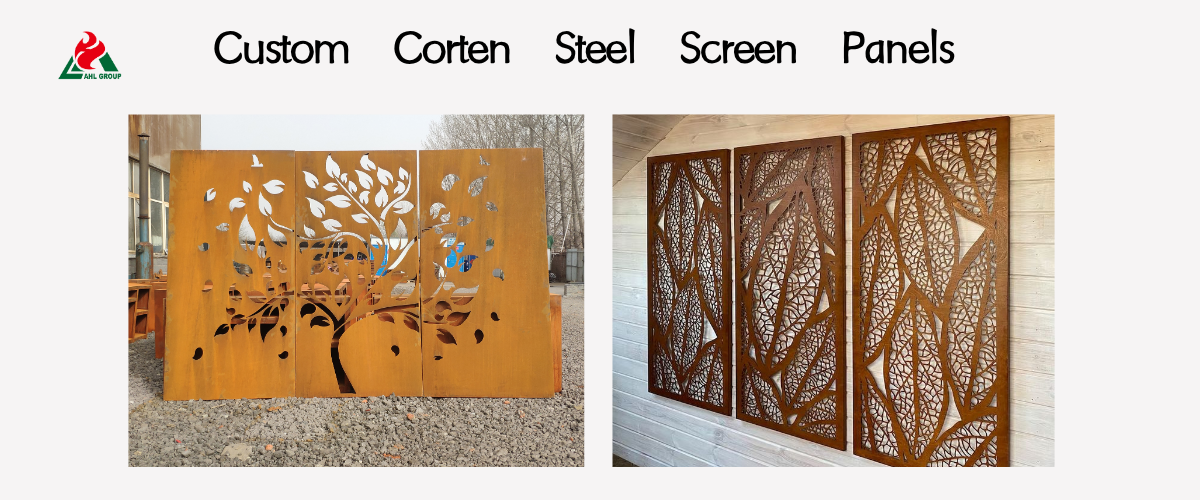

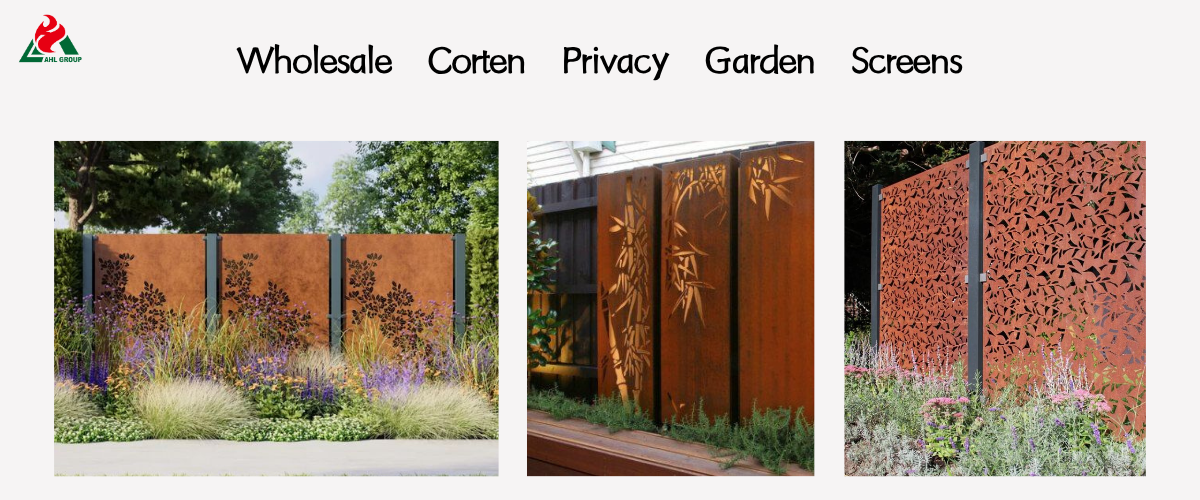

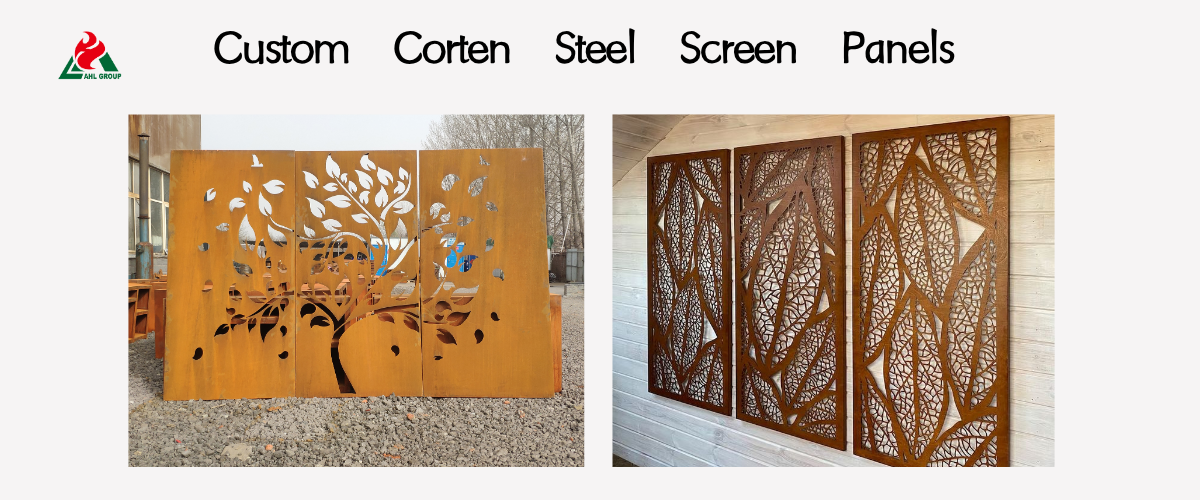

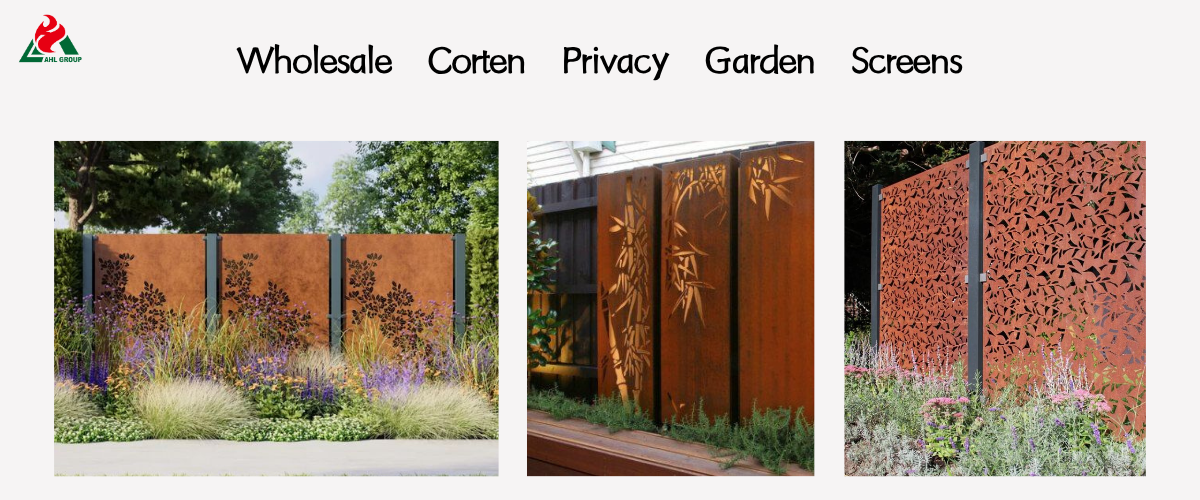

Corten steel screens have become synonymous with modern high-end landscape architecture. Their striking rusted texture seamlessly blends industrial strength with natural warmth, making them the material of choice for privacy barriers, artistic facades, and garden dividers. While their aesthetic value is undeniable, achieving a flawless and enduring installation hinges on a frequently overlooked engineering decision: determining the correct steel plate thickness. This guide cuts to the core, offering authoritative and professional recommendations for screen thickness based on application scenarios, stability, and durability requirements—empowering you to make precise decisions.

When customizing Corten steel screens, the final visual effect is often the primary consideration. However, the critical decisions affecting the screen's lifespan, stability, and cost lie in the thickness of its plates. Selecting the appropriate thickness is not merely an aesthetic choice but a core technical parameter that must align with the screen's intended purpose and exposure level.

The ideal thickness for weathering steel screens varies significantly by application: purely decorative panels (such as backlit art panels) require vastly different thicknesses than load-bearing structures (like tall privacy fences in windy regions). Manufacturers like AHL Group determine specifications through engineering calculations to prevent screen warping and ensure compliance with local safety standards. Properly specified screens represent an investment, maintaining their flat, sharp form for decades.

Thickness is a balancing act. Thinner materials offer lighter weight and lower costs but sacrifice rigidity, potentially causing slight deformation in large-span structures. Thicker materials provide superior rigidity and impact resistance but significantly increase weight, cost, and manufacturing complexity—especially for intricate laser-cut designs.

Selecting the appropriate steel thickness is the primary step in ensuring project success. The following ranges represent industry standard recommendations for Corten steel screen panels.

Indoor screens are shielded from environmental stresses (wind, rain, thermal cycling), allowing design focus on weight reduction and structural complexity. Thinner gauges (e.g., 14 or 16 gauge, approximately 1.5mm to 2mm) offer easier fabrication, lower shipping costs, and enable the most intricate laser-cut patterns.

This represents the most common thickness range for residential landscaping projects. A 2.5mm thickness is often considered optimal, providing sufficient rigidity to withstand light wind loads while maintaining a flat appearance across spans up to 1.8 meters. This thickness also keeps fabrication and material costs reasonable. For residential privacy screens intended for long-term use, AHL Group typically defaults to a 3mm specification to maximize customer satisfaction.

For screen panels used on commercial building facades or tall continuous fencing, increased thickness is required. Panels exceeding 2.5 meters (approximately 8.2 feet) in height must use at least 3mm to 4mm specifications to withstand gravity and wind pressure, ensuring the screen remains vertically aligned with the support frame.

In high-impact zones, structural applications (such as retaining wall supports), or when metal screens function as safety barriers, 4.5mm or thicker specifications are mandatory. The increased mass delivers superior rigidity, vibration damping, and conveys the ultimate durability and premium quality often demanded by municipal projects or large corporate developments.

Understanding technical trade-offs is crucial when using weathering steel in budget and design planning.

Thickness directly determines weight. For identical dimensions, a 3mm-thick screen will weigh 50% more than a 2mm-thick counterpart. This additional weight necessitates sturdier, more expensive columns, heavier hardware, and potentially more complex installation equipment. For large curtain wall projects, structural engineers must calculate total loads (including wind loads) based on the thickness of the weathering steel sheets.

► Thin Gauge (<3mm): Ideal for laser-cut screens with intricate, small details. Easier to bend and form.

► Thick Gauge (>4mm): Laser cutting speeds slow down for complex designs, increasing costs, and the minimum bend radius increases. Welding thick weathering steel plates requires specialized high-current equipment and more filler material. However, thicker steel avoids the “rippling” or minor thermal deformation that occurs when welding thin metals.

Material cost is the primary factor in weathering steel fabrication. Increasing plate thickness from 2 mm to 4 mm roughly doubles the price. While fabrication processes vary slightly, rising material costs are the main driver of final pricing. Therefore, selecting the minimum effective thickness is crucial for budget control.

The following examples illustrate the rationale for selecting specific thicknesses:

A typical 1.8m × 1.2m residential privacy screen requires embedding into a concrete foundation. The 2.5mm thickness strikes an optimal balance between cost-effectiveness and lateral wind resistance, ensuring the screen maintains visual flatness and aesthetics without necessitating oversized support columns.

Commercial building facades utilize 4 mm-thick weathering steel. This heavy-duty specification withstands high-altitude wind loads while providing robust mounting points for integrated lighting. It ensures large panels remain free of visual rippling or deformation, conveying enduring quality.

Public artworks often require both malleability and durability. The 3mm specification provides sufficient thickness to withstand minor vandalism and impact while accommodating the complex bending and welding techniques needed for three-dimensional sculptural designs.

Incorrect specifications may lead to issues that are difficult or impossible to rectify after installation, with costly repairs.

► Bending Deformation: Most commonly occurs in panels with spans exceeding 1.5 meters and thicknesses ≤2mm, particularly in areas exposed to intense sunlight (thermal deformation).

► Weld Deformation: Thin steel is prone to distortion during welding, preventing the finished product from achieving perfect flatness.

► Visual Fragility: Thin screens may appear cheap in appearance and texture, diminishing the investment value of premium materials like weathering steel.

► Excessive Cost and Weight: Over-specifying thickness significantly inflates material costs and requires heavy machinery and specialized installation teams.

► Limited Design Details: Ultra-thick panels restrict the precision achievable with laser cutting and necessitate larger radius corners in design.

► Increased Installation Difficulty: Hoisting and securing excessively heavy panels poses significant logistical challenges and drives up labor costs.

Yes, but they must be equipped with sufficient structural support. Thin screens (1.5mm) for outdoor use require rigid frame reinforcement with heavy-duty steel or aluminum along all four edges to prevent deformation and bending caused by wind forces and thermal cycling.

For any freestanding outdoor screens, AHL Group typically recommends a minimum thickness of 2.5mm to ensure structural durability, surface flatness, and long-term performance under moderate climatic conditions.

Thickness does not alter the rate or color of patina formation, which is determined by alloy composition and environment. However, since the corrosion process slightly reduces overall thickness, thicker components (4 mm) exhibit a longer overall service life compared to thinner ones (2 mm).

The ideal thickness for Corten metal screens must be determined through precise technical calculations that balance cost, structural stability, and aesthetic objectives. For standard residential privacy screens, a thickness of 2.5 to 3 millimeters offers the best cost-performance ratio and functionality. For large-scale or commercial projects, it is essential to consult manufacturers like AHL Group, who specialize in thermal loads and wind loads, to ensure a flawless and enduring installation that maximizes your return on investment in weathering steel.

Technical Specifications for Corten Steel Screens

When customizing Corten steel screens, the final visual effect is often the primary consideration. However, the critical decisions affecting the screen's lifespan, stability, and cost lie in the thickness of its plates. Selecting the appropriate thickness is not merely an aesthetic choice but a core technical parameter that must align with the screen's intended purpose and exposure level.

From Aesthetic Choices to Structural Decisions

The ideal thickness for weathering steel screens varies significantly by application: purely decorative panels (such as backlit art panels) require vastly different thicknesses than load-bearing structures (like tall privacy fences in windy regions). Manufacturers like AHL Group determine specifications through engineering calculations to prevent screen warping and ensure compliance with local safety standards. Properly specified screens represent an investment, maintaining their flat, sharp form for decades.

How Thickness Influences Form and Function

Thickness is a balancing act. Thinner materials offer lighter weight and lower costs but sacrifice rigidity, potentially causing slight deformation in large-span structures. Thicker materials provide superior rigidity and impact resistance but significantly increase weight, cost, and manufacturing complexity—especially for intricate laser-cut designs.

Recommended Thickness Ranges by Application

Selecting the appropriate steel thickness is the primary step in ensuring project success. The following ranges represent industry standard recommendations for Corten steel screen panels.

Decorative Interior Screens (1.5 mm - 2 mm)

Indoor screens are shielded from environmental stresses (wind, rain, thermal cycling), allowing design focus on weight reduction and structural complexity. Thinner gauges (e.g., 14 or 16 gauge, approximately 1.5mm to 2mm) offer easier fabrication, lower shipping costs, and enable the most intricate laser-cut patterns.

Standard Garden Privacy Screens (2mm - 3mm)

This represents the most common thickness range for residential landscaping projects. A 2.5mm thickness is often considered optimal, providing sufficient rigidity to withstand light wind loads while maintaining a flat appearance across spans up to 1.8 meters. This thickness also keeps fabrication and material costs reasonable. For residential privacy screens intended for long-term use, AHL Group typically defaults to a 3mm specification to maximize customer satisfaction.

Large Architectural Screens (3mm to 4.5mm)

For screen panels used on commercial building facades or tall continuous fencing, increased thickness is required. Panels exceeding 2.5 meters (approximately 8.2 feet) in height must use at least 3mm to 4mm specifications to withstand gravity and wind pressure, ensuring the screen remains vertically aligned with the support frame.

Structural and Commercial Applications (4.5mm and Above)

In high-impact zones, structural applications (such as retaining wall supports), or when metal screens function as safety barriers, 4.5mm or thicker specifications are mandatory. The increased mass delivers superior rigidity, vibration damping, and conveys the ultimate durability and premium quality often demanded by municipal projects or large corporate developments.

| Application Type |

Recommended Thickness (mm) | Key Design Consideration |

| Decorative Interior Screens |

1.5mm – 2mm | Low weight, ease of installation, finer laser-cut detail. |

| Standard Garden Privacy Screens |

2mm – 3mm | Essential rigidity for wind exposure; balances cost and durability. |

| Large Architectural Screens |

3mm – 4.5mm | Required for tall panels (over 2.5m) to prevent bowing and provide structural safety. |

| Structural and Commercial Applications |

4.5mm+ | Load-bearing capacity, impact resistance, and maximum perceived quality. |

Technical Considerations for Different Thicknesses

Understanding technical trade-offs is crucial when using weathering steel in budget and design planning.

Impact of Weight on Supporting Structures

Thickness directly determines weight. For identical dimensions, a 3mm-thick screen will weigh 50% more than a 2mm-thick counterpart. This additional weight necessitates sturdier, more expensive columns, heavier hardware, and potentially more complex installation equipment. For large curtain wall projects, structural engineers must calculate total loads (including wind loads) based on the thickness of the weathering steel sheets.

Manufacturing Limitations and Possibilities

► Thin Gauge (<3mm): Ideal for laser-cut screens with intricate, small details. Easier to bend and form.

► Thick Gauge (>4mm): Laser cutting speeds slow down for complex designs, increasing costs, and the minimum bend radius increases. Welding thick weathering steel plates requires specialized high-current equipment and more filler material. However, thicker steel avoids the “rippling” or minor thermal deformation that occurs when welding thin metals.

Cost Implications of Different Thickness Options

Material cost is the primary factor in weathering steel fabrication. Increasing plate thickness from 2 mm to 4 mm roughly doubles the price. While fabrication processes vary slightly, rising material costs are the main driver of final pricing. Therefore, selecting the minimum effective thickness is crucial for budget control.

Case Studies: Thickness in Real Projects

The following examples illustrate the rationale for selecting specific thicknesses:

Residential Garden Screen (2.5mm)

A typical 1.8m × 1.2m residential privacy screen requires embedding into a concrete foundation. The 2.5mm thickness strikes an optimal balance between cost-effectiveness and lateral wind resistance, ensuring the screen maintains visual flatness and aesthetics without necessitating oversized support columns.

Commercial Building Facades (4 mm)

Commercial building facades utilize 4 mm-thick weathering steel. This heavy-duty specification withstands high-altitude wind loads while providing robust mounting points for integrated lighting. It ensures large panels remain free of visual rippling or deformation, conveying enduring quality.

Public Art Installations (3mm)

Public artworks often require both malleability and durability. The 3mm specification provides sufficient thickness to withstand minor vandalism and impact while accommodating the complex bending and welding techniques needed for three-dimensional sculptural designs.

Consequences of Selecting Incorrect Thickness

Incorrect specifications may lead to issues that are difficult or impossible to rectify after installation, with costly repairs.

Problems with Excessively Thin Screens

► Bending Deformation: Most commonly occurs in panels with spans exceeding 1.5 meters and thicknesses ≤2mm, particularly in areas exposed to intense sunlight (thermal deformation).

► Weld Deformation: Thin steel is prone to distortion during welding, preventing the finished product from achieving perfect flatness.

► Visual Fragility: Thin screens may appear cheap in appearance and texture, diminishing the investment value of premium materials like weathering steel.

Drawbacks of Excessively Thick Screens

► Excessive Cost and Weight: Over-specifying thickness significantly inflates material costs and requires heavy machinery and specialized installation teams.

► Limited Design Details: Ultra-thick panels restrict the precision achievable with laser cutting and necessitate larger radius corners in design.

► Increased Installation Difficulty: Hoisting and securing excessively heavy panels poses significant logistical challenges and drives up labor costs.

Frequently Asked Questions About Corten Screens

Q: Can Thin Screens Be Used Outdoors?

Yes, but they must be equipped with sufficient structural support. Thin screens (1.5mm) for outdoor use require rigid frame reinforcement with heavy-duty steel or aluminum along all four edges to prevent deformation and bending caused by wind forces and thermal cycling.

Q: What Is the Minimum Thickness Required for Durability?

For any freestanding outdoor screens, AHL Group typically recommends a minimum thickness of 2.5mm to ensure structural durability, surface flatness, and long-term performance under moderate climatic conditions.

Q: How Does Thickness Affect the Patina Formation Process?

Thickness does not alter the rate or color of patina formation, which is determined by alloy composition and environment. However, since the corrosion process slightly reduces overall thickness, thicker components (4 mm) exhibit a longer overall service life compared to thinner ones (2 mm).

Conclusion: Creating Mysterious Ambiance with Corten Steel Screens

The ideal thickness for Corten metal screens must be determined through precise technical calculations that balance cost, structural stability, and aesthetic objectives. For standard residential privacy screens, a thickness of 2.5 to 3 millimeters offers the best cost-performance ratio and functionality. For large-scale or commercial projects, it is essential to consult manufacturers like AHL Group, who specialize in thermal loads and wind loads, to ensure a flawless and enduring installation that maximizes your return on investment in weathering steel.