For the hospitality industry, landscape architects, and discerning homeowners, standard BBQ grills often fall short of fulfilling unique design visions. This raises the question: Can Corten steel BBQ grills be customized? The answer is unequivocally YES—customization is not only feasible but also a core specialty of professional manufacturers like AHL Group. This guide comprehensively explores the limitless possibilities of creating bespoke weathering steel grills, precisely tailored to your spatial layout, functional requirements, and aesthetic vision. It details the end-to-end collaborative process from initial design to global delivery.

1. Introduction: Beyond Standard Models – Defining Your Unique Outdoor Kitchen

The Growing Demand for Personalized Outdoor Living Spaces

Outdoor kitchens have evolved from simple cooking areas into central entertainment hubs and key architectural features in resorts, restaurants, and luxury residences. The 2026 Landscape Architecture Survey reveals that 75% of high-end residential projects now feature fully customized outdoor cooking areas—a significant increase from 60% five years ago. This shift fuels market demand for multifunctional equipment—not only practical, but also seamlessly integrated, durable, and perfectly aligned with the space's design language.

Yes, You Can! An Overview of AHL Corten’s Custom Fabrication Capabilities

As a professional weathering steel manufacturer and OEM/ODM partner with over two decades of experience, customization is standard for us. Our factory is equipped with CNC plasma cutters, hydraulic press brakes, robotic welding arms, and a team of seasoned craftsmen. We can create single-piece signature outdoor grills for private villas or produce uniform product lines of over 500 units for global brands. The fusion of technology and craftsmanship enables us to transform complex visions into durable, high-performance realities.

2. The Scope of Customization: What Can Be Tailored?

Dimensional Flexibility: Size, Shape, and Cooking Surface Area

The most common customization request involves size adjustments. We can flexibly modify length, width, height, and cooking area dimensions to align with your courtyard layout or commercial kitchen design. Beyond standard rectangles, we craft curved, L-shaped, T-shaped, or radial designs to seamlessly integrate into corner spaces or wrap around architectural features. For island countertop installations, we precisely calculate exposed dimensions and flange details to achieve a visually seamless integration.

Functional Components: Grill Grates, Burners, Shelves, and Accessories

Functional design tailored to your cooking style and needs:

► Cooking Systems & Fuel: Choose charcoal (for authentic flavor), propane (convenient and globally compatible), natural gas (for fixed large-capacity installations in North America), or even hybrid models. Customize burner count, type (infrared burners for perfect searing, standard radiant burners, or ceramic burners for rotisserie cooking), and heat output (15,000 to 60,000+ BTUs per burner) to match your culinary demands.

► Grill Grates & Cooking Surfaces: Choose from 10mm round or flat stainless steel grates, heavy-duty cast iron grates with superior heat retention, or combination systems. Optionally add a flat griddle (steel surface) for seafood, pancakes, or tacos.

► Integrated Expansion Components: Design options include side burners, dedicated smoker boxes with independent airflow control, ceramic pizza ovens, warming drawers, refrigerated bases, stainless steel door storage cabinets, or custom tool racks and towel bars.

Aesthetic Details: Distressed Finishing, Leg Design, and Brand Elements

Mastering the ultimate details that define the final appearance:

► Antique Bronze Finish: Choose from Natural Weathering (develops unique character over 6-18 months), Accelerated Pre-Weathering (factory-applied stable deep bronze layer for instant “aged elegance”), or Oil-Based Coating (delays oxidation for a strong semi-gloss metallic effect).

► Legs, Frame & Mobility: Choose minimalist square legs, architectural cylindrical supports, industrial-grade locking casters, or a suspended cantilever base. Leg height is adjustable for ergonomic comfort.

► Branding and detailing: Supports laser-cut logos, serial nameplates, custom geometric ventilation cutouts, or hammered-texture side panels. Full private-label management services available for branded products.

3. The Collaborative Customization Process: From Idea to Installation

Step 1: Initial Consultation—Defining Requirements and Vision (OEM/ODM Inquiry)

We initiate projects through structured consultations to comprehensively grasp project scope, target markets, budgets, regulatory environments, and key performance requirements. For commercial clients, we explore daily coverage capacity; for distributors, we analyze market gaps. This phase establishes a clear project charter and completes feasibility assessments.

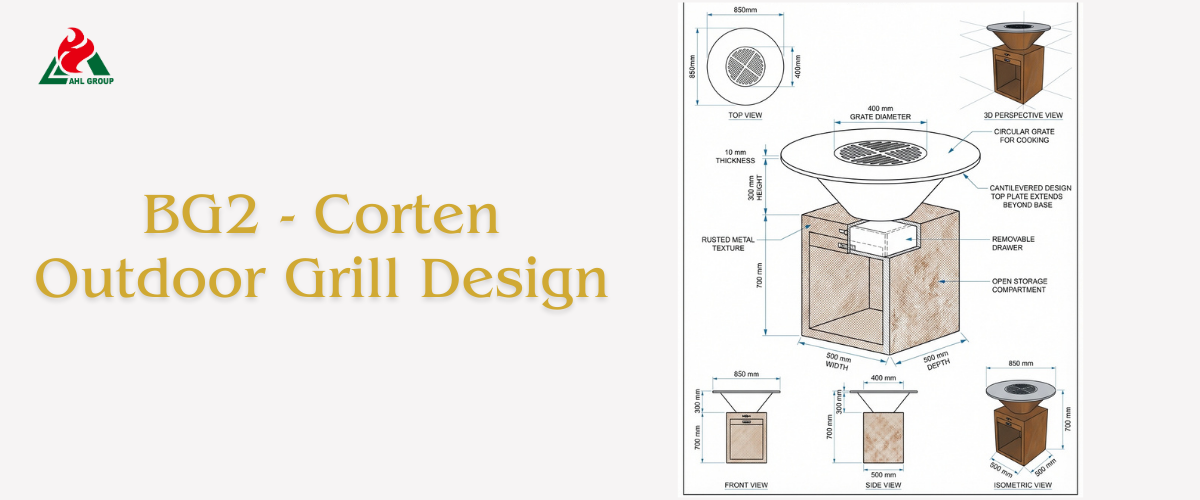

Step 2: Design and Technical Drawing Development

Our engineering team utilizes AutoCAD and SolidWorks software to produce detailed 1:1 scale CAD drawings, isometric views, and photorealistic 3D renderings. These documents precisely annotate all parameters: material thicknesses (e.g., 5mm bowl body, 3mm side panels), weld types, thermal expansion gaps, and load-bearing calculations. Serving as the manufacturing contract blueprint, these files require your signed approval before proceeding.

Step 3: Prototype Sampling and Confirmation

For new or complex designs, we will produce full-scale working prototypes or “form/function consistent” samples of critical components. You can personally experience their ergonomic design, flame distribution, insulation performance, and overall aesthetic appeal. All adjustments will be finalized during this phase to ensure the final mass production fully meets your expectations.

Step 4: Manufacturing, Quality Control, and Global Logistics

Following final approval, production commences at our factory. Each unit undergoes 12 quality control inspections, including gas line pressure testing, weld leak detection, and surface oxide layer uniformity checks. We then design customized layered foam packaging for secure ocean shipping, managing all export documentation, certification procedures, and door-to-door logistics delivery to your designated destination.

4. Material and Craftsmanship: The Foundation of a Premium Custom Grill

Core Material: Selecting the Right Corten Grade and Thickness for Durability

We exclusively use premium, mill-certified Grade A weathering steel (ASTM A588/EN 10025-5). For furnace chambers, we recommend a thickness of 5-6mm or greater to withstand thermal cycling deformation; main panels utilize 3-4mm thickness to achieve the optimal strength-to-weight ratio. This material ensures a thermal expansion coefficient of approximately 11×10⁻⁶/°C, a parameter integrated into all joint designs.

Engineering for Heat: Structural Integrity and Heat Distribution

Custom designs undergo thermal simulation validation to effectively prevent hot spots and ensure efficiency. Internal baffles guide heat and flue gas flow, while critical double-wall sections feature ceramic fiber insulation. Burner orifices are optimized via Venturi effect calculations for air-fuel mixing. The structural support not only bears the weight of the grill but also withstands the additional load when the integrated marble countertop is fully loaded.

Welding and Finishing: The Hallmarks of Quality Fabrication

Critical visible welds utilize the Gas Tungsten Arc Welding (GTAW/TIG) process, achieving oxidation-free, precisely flush connections; high-strength structural welds employ Gas Metal Arc Welding (GMAW/MIG). All edges undergo milling or grinding to create safety-rounded corners. Surface treatment processes—whether natural oxidation or forced glazing with proprietary solutions—are strictly controlled to ensure environmental compliance and process consistency.

5. Advantages of Choosing a Custom Corten Steel Grill

Perfect Fit: Designed for Your Specific Space and Usage Needs

Custom barbecue grills solve unique spatial constraints—whether adapting to a narrow urban balcony or spanning the entire length of a resort pool deck. They're optimized for your specific use cases, whether slow-roasting a 12-hour beef brisket or quickly searing steaks for 50 hotel guests.

Brand Alignment: Creating a Cohesive Look for Commercial Projects

For hotels, restaurants, and high-end real estate developments, distinctive grills serve as architectural assets that define brand identity. They create memorable guest experiences while delivering stunning marketing imagery. For distributors, proprietary custom collections build brand loyalty and secure profit margins by offering exclusive products.

Long-Term Value: Superior Durability and Unique Design as an Investment

Custom-built, heavy-gauge Corten BBQ grills serve as permanent, zero-maintenance installations. Their longevity completely overturns the 5-7 year replacement cycle typical of inexpensive coated steel grills. Functioning as functional art, they enhance property value—landscape architects confirm that premium outdoor kitchen facilities deliver high return on investment.

6. Inspiration Gallery: Examples of Successful Custom Grill Projects

High-End Residential: A Matching Corten Grill and Outdoor Kitchen Suite in Switzerland

A central barbecue island for an Alpine villa, featuring a 120cm gas grill, a matching weathering steel wood-burning fireplace, and a tiered planter combination. All components utilize the identical “Mountain Grey” rust patina formula (achieved through a controlled weathering process simulating high-altitude environments), with custom laser-engraved edelweiss motifs on the door panels.

Dealer Product Line: Private Label “Chef's Atlas” Series for Dutch Distributors

We co-developed three modular grills (80cm, 100cm, 120cm) featuring exclusive dealer branding and distinctive diamond-patterned heat shields. The series includes custom marketing collateral, technical specifications, and point-of-sale displays to empower dealers in launching a new premium product line.

Conclusion: Getting Started with Your Custom Project

How to Prepare for Consultation (Key Questions Answered)

To expedite the process, please prepare the following information:

► Project Overview: Residential/Commercial use? Estimated usage frequency (meals per week/event capacity)?

► Space & Technical Requirements: Available floor area (length × width × height), fixed installations (gas line location/type, electrical outlets), preferred primary/secondary cooking methods?

► Market & Compliance: Target country/region? Any known certification requirements (e.g., CE, ANSI)?

► Aesthetic Direction: Design inspiration portfolio, desired surface finishes, surrounding materials (e.g., stone, wood, concrete)?

► Commercial Parameters: Target unit price, projected annual sales volume, required delivery timeline?

Understanding the Timeline and Investment for Custom Products

Custom projects require dedicated design and mold development. Typically, the design and prototyping phase takes 4-6 weeks, with the initial production run taking 8-12 weeks. While the initial investment is higher than that of off-the-shelf products, unit costs decrease significantly with increased production volume. The benefits of a product that perfectly aligns with your needs and enhances brand value far outweigh the additional costs.

Contact AHL Group to Begin Your Custom Grill Design Journey

Your vision for the perfect outdoor cooking center is entirely achievable. Reach out to our dedicated OEM/ODM project team today to schedule a technical consultation, discuss your creative ideas, and receive an initial project assessment. Leveraging our expertise in custom weathering steel fabrication, we'll bring your unique modern grill design to life.