In the fiercely competitive outdoor cooking equipment market, the term “durability” is often thrown around carelessly. Most consumers have long accepted a five-year replacement cycle: buying a standard black-painted steel grill, watching the paint peel in the second year, seeing rust holes appear in the fourth, and inevitably replacing it by the fifth.

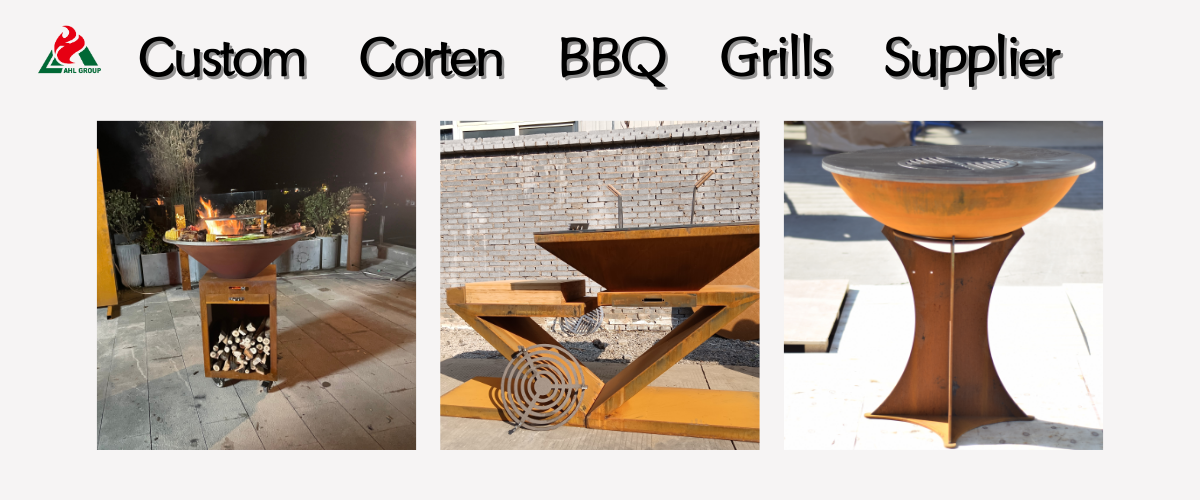

AHL Group is redefining this timeline. By incorporating weathering steel (Corten steel) into our professional grill series, we create products designed not just for a few seasons—but for a lifetime. This guide delves into the tenfold lifespan advantage of Corten steel grills over standard carbon steel alternatives, revealing the engineering and metallurgical principles behind this durability.

AHL Group is redefining this timeline. By incorporating weathering steel (Corten steel) into our professional grill series, we create products designed not just for a few seasons—but for a lifetime. This guide delves into the tenfold lifespan advantage of Corten steel grills over standard carbon steel alternatives, revealing the engineering and metallurgical principles behind this durability.

Introduction: Redefining Grill Longevity

Barbecuing grills are among the most vulnerable appliances in the home. They endure extreme thermal shocks—rapidly heating from freezing ambient temperatures to 400°C—while constantly exposed to oxygen, moisture, and corrosive salt particles.

The Limitations of Ordinary Steel: Inevitable Rust and Damage

Ordinary carbon steel is chemically unstable in outdoor environments. To prevent it from reverting to its natural state (iron oxide), manufacturers apply high-temperature-resistant paints or powder coatings. However, these coatings are brittle and rigid. As the grill expands and contracts during heating cycles, the coating develops micro-cracks. Once moisture infiltrates these cracks, rust begins to corrode the steel from within, silently spreading beneath the flaking surface.

Weathering Steel Solution: A Material Born for Eternity

Originally used in bridge construction and shipping containers, weathering steel embodies the opposite philosophy. Rather than relying on fragile artificial coatings to combat rust, it transforms corrosion into its primary defense mechanism. This “planned oxidation” allows AHL Group BBQ grills to maintain structural integrity for decades without any coatings.

The 10x Factor: A Breakdown of the Lifespan Multiplier

When we claim “10x lifespan,” we refer to the comparative structural integrity of the firebox and chassis over long-term use.

Standard steel: Severe corrosion appears within 3-5 years

In typical outdoor environments, standard 2mm steel grills experience significant annual wall thickness loss. Once coatings fail, rust becomes “active” and “flaky.” Flaking rust exposes fresh metal surfaces to further oxidation. This cycle continues until metal walls become paper-thin, ultimately leading to combustion chamber perforation within 3 to 5 years.

Corten Steel: 30-50+ years of structural integrity

Weathering steel (ASTM A588) does not produce flaking rust layers. After the initial rust layer forms (typically within 6-12 months), the corrosion rate drops to near zero. In most terrestrial environments, weathering steel exhibits an annual corrosion loss rate below 0.01mm. This means a 3mm-thick AHL Group Corten BBQ grill maintains stable structural integrity well into the next century.

Mathematical and Empirical Basis for the “10x Lifespan” Claim

Bridge engineering research data indicate that weathering steel exhibits 4 to 8 times greater atmospheric corrosion resistance than ordinary carbon steel. When accounting for the “high-temperature accelerated corrosion” factor in barbecue grills (where standard steel deteriorates faster), the functional lifespan gap expands to a 10x magnitude.

Core Reason 1: The Self-Protecting Patina

To understand the enduring durability of AHL Group's BBQ grills, one must first grasp the mystery of the “rust layer.”

How Rust Becomes a Shield, Not a Disease

In ordinary steel, rust acts like a disease eroding its host. In weathering steel, however, the rust layer transforms into a protective shield. Initial oxidation forms a dense, amorphous layer of iron hydroxide. This layer is non-porous, creating a physical barrier that blocks oxygen and water molecules from corroding the underlying “unrusted” steel.

Ordinary Steel: Rust Penetration Leads to Strength Decline

Conventional rust layers are porous and hygroscopic—they absorb moisture that adheres to the metal surface, accelerating their own corrosion process.

Weathering Steel: Rust Layer Forms a Sealed Protection

The rust layer on weathering steel effectively “seals” the surface. Even if the surface is scratched, the exposed steel automatically forms a new rust layer, achieving “self-repair.” This is precisely why AHL Group's outdoor grills require no additional rust-proof coating.

Core Reason 2: Superior Alloy Composition

The "magic" of Corten lies in its chemical recipe.

The Role of Copper, Chromium, and Nickel in Corrosion Resistance

AHL Group weathering steel is rich in specific alloying elements:

► Copper: The primary element promoting the formation of a dense rust layer.

► Chromium: Enhances the steel's high-temperature oxidation resistance.

► Nickel: Improves the toughness of the rust layer.

These elements work synergistically to ensure the oxidation process is self-limiting.

Ordinary Steel: Basic Iron-Carbon Structure, Highly Reactive

Ordinary steel lacks these expensive alloying elements, consisting essentially of pure iron and carbon. This makes it highly reactive to moisture in the air. Without the “anchoring” effect of copper, the rust layer can only flake off and peel away.

Core Reason 3: Heat Resistance and Structural Stability

The grill is the furnace. Heat resistance is as crucial as rain resistance.

Maintains Strength and Shape Through Thousands of Heating Cycles

Weathering steel exhibits higher yield strength than ordinary steel at elevated temperatures. This ensures AHL Group outdoor BBQ grills retain their geometric integrity during intense grilling sessions. Its likelihood of “warping” or “bending” is far lower than that of cheap grills—a common failure point in which the lid fails to close tightly after one year of use.

Standard Steel: Warping, Thinning, and Fatigue Over Time

Ordinary carbon steel is more prone to “thermal fatigue.” Each heating cycle causes the expanding rust layer to peel off, thinning the metal and making it more susceptible to deformation during subsequent use.

Maximizing Your Investment

While Corten steel barbecue grills can last for decades, proper maintenance can further extend their lifespan.

Simple Care That Further Extends the Already Extended Lifespan

Keep the firebox free of wet ash. Ash is alkaline and reacts with water to form a corrosive “paste” that can even erode weathering steel. Maintenance is as simple as a quick sweep after the BBQ grill has cooled.

The One Thing That Can Shorten a Corten Grill's Life (And How to Avoid It)

Prolonged immersion. Weathering steel requires a “wet-dry cycle” to maintain its protective rust layer. If the Corten grill sits in standing water or is constantly sprayed by lawn sprinklers, the rust layer cannot “breathe” and stabilize. Ensure your AHL Group grill is placed on well-drained ground.

Frequently Asked Questions About Corten Grill

Q: If It Rusts, How Can It Possibly Last Longer?

Because this “rust” is only 0.05 millimeters deep. It acts as an oxidized protective layer that prevents further corrosion. Think of it as nature's own self-healing “paint.”

Q: Can a Corten Grill Be Left Outside Uncovered in Winter?

Yes. In fact, we recommend it. Rain and snow help deepen and mature the rust layer. AHL Group grills are among the few outdoor appliances that truly live up to the “set it and forget it” promise.

Q: Won't the Inside of the Firebox Rust Through from the Intense Heat and Ashes?

No. AHL Group uses structural-grade weathering steel (3-10mm thick, depending on model). Compared to the steel's overall quality, the “wear” caused by high-temperature ash is negligible.

Q: If It's So Durable, Why Shouldn't I Cook Food Directly on the Corten Steel Surface?

Weathering steel serves solely as structural support, not a cooking surface. To ensure food safety and efficient heat transfer, AHL Group BBQ grills feature heavy-duty carbon steel or stainless steel “flat cooking plates” as the actual cooking area. The weathering steel body provides an eternal protective shell for this cooking surface.

Conclusion: The Ultimate Value Proposition

Choosing the AHL Group Corten outdoor grill signifies a shift from consumer thinking to investor thinking. Your initial premium investment will save you the cost and waste of purchasing ten ordinary grills over the next fifty years. This product is built on three core principles: sustainability, structural excellence, and timeless industrial aesthetics.

When you purchase an AHL Group grill, you acquire more than a cooking tool—you gain a family heirloom to pass down to future generations.

Ready to upgrade to a BBQ grill built to last a lifetime? Contact AHL Group today for our complete product catalog and wholesale pricing.