When architects and designers select Corten steel cladding for building facades, they invest not merely in a material, but in a dynamic, evolving aesthetic choice. Weathering steel's profoundly rustic patina and distinctive texture create a compelling architectural statement.

But for any long-term building project, a natural and critical question arises: How Long Does Corten Steel Cladding Last?

As the manufacturing experts behind AHL Group's premium weathering steel architectural solutions, we can unequivocally state: When properly specified and installed, weathering steel boasts an astonishing lifespan—measured in decades, not years. This guide delves into the science behind its durability and reveals the key factors that ensure its enduring performance.

But for any long-term building project, a natural and critical question arises: How Long Does Corten Steel Cladding Last?

As the manufacturing experts behind AHL Group's premium weathering steel architectural solutions, we can unequivocally state: When properly specified and installed, weathering steel boasts an astonishing lifespan—measured in decades, not years. This guide delves into the science behind its durability and reveals the key factors that ensure its enduring performance.

What is Corten Steel?

Corten steel, scientifically known as weathering steel, is not a typical steel alloy. Its exceptional longevity stems from a highly controlled oxidation process.

Science Behind Corten Steel

Weathering steel is a category of paint-free steel alloys (such as ASTM A588, A242, and A606-4 standards) whose secret lies in precisely proportioned alloying elements—primarily copper, chromium, and phosphorus. When exposed to wet-dry weather cycles, these elements accelerate the steel's rusting process.

Unlike ordinary carbon steel, which forms flaky, porous rust layers (accelerating moisture penetration and structural corrosion), the protective layer developed by weathering steel exhibits a fundamental difference.

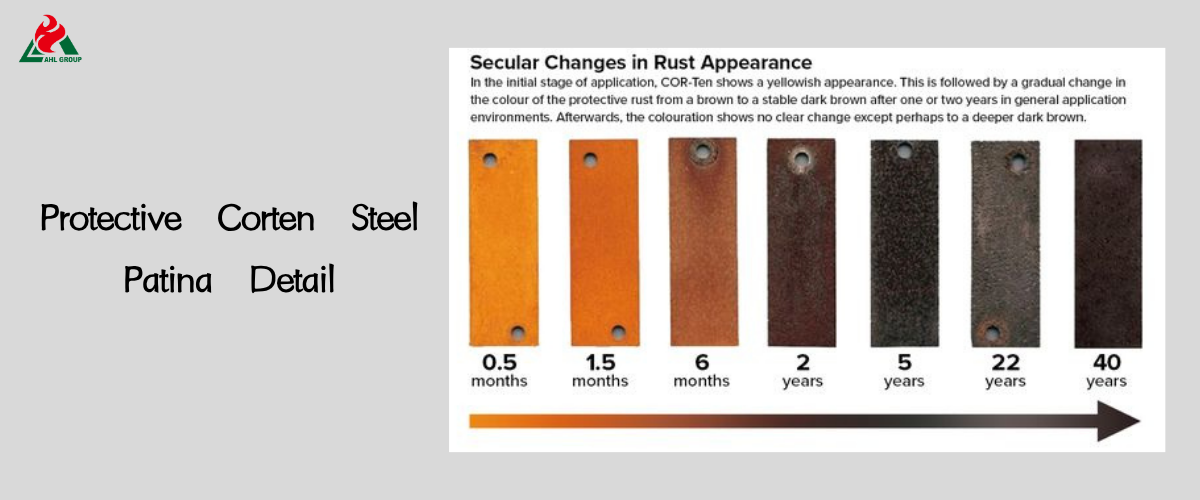

Protective Rust Layer Formation Mechanism

The initial rust layer on Corten steel appears porous and orange, resembling ordinary rust. However, as wet-dry cycles persist, the copper and phosphorus components in the alloy react to form a dense, stable oxide layer—the rust protective layer.

This rust layer exhibits a deep earthy brown hue, with its key feature being the formation of a protective barrier tightly adhering to the substrate. This barrier significantly slows deep corrosion rates, effectively sealing the material and imparting exceptional durability to weathering steel. For the protective layer to fully form and stabilize, the material must undergo cycles of wetting and thorough drying.

Expected Service Life of Corten Steel Cladding

Service life directly depends on the steel's ability to maintain a stable rust layer. Under suitable environmental conditions, it demonstrates exceptional durability.

Industry Standards and Warranty Periods

Although Corten steel has no “expiration date,” once the rust layer stabilizes, it is generally considered a maintenance-free material. The key to its structural durability lies in the extremely low metal loss rate following the initial weathering period.

For AHL Group's high-quality cladding, when using standard thicknesses (e.g., 3mm to 6mm), structural integrity is typically designed to match the building's lifespan. Structural engineers commonly set the service life of weathering steel cladding at 60 to 80 years, potentially longer under favorable conditions.

Case Study: Corten Cladding in Use for 50+ Years

The exceptional durability of weathering steel is evidenced by its application in major architectural projects. Buildings such as the John Deere Global Headquarters, constructed in the 1960s, and the former CBS Building demonstrate the material's enduring performance. These examples show that after decades of use, the cladding retains its aesthetic appeal and structural integrity, typically requiring no additional maintenance beyond routine visual inspections.

Factors That Influence Longevity

The durability of Corten steel facades is not absolute; its performance largely depends on the environmental conditions and the design choices made.

Environmental Conditions and Corrosivity

The service life of Corten steel is primarily influenced by two environmental factors:

• High Chloride Content: Environments near saltwater (coastal areas) or heavy use of deicing salts accelerate corrosion. Salt spray damages the stable rust layer, hinders protective layer formation, and intensifies corrosion rates.

• Persistent Moisture: Weathering steel requires alternating wet and dry cycles to develop its protective rust layer. Prolonged exposure to moisture (e.g., standing water areas or extremely humid climates preventing drying) may prevent stable protective oxide formation, accelerating deterioration. Dry climates or low-humidity environments are most ideal.

The Importance of Proper Installation and Detailing

Even with the highest quality Corten steel panels, improper installation can still lead to localized failure points. Key details include:

• Drainage System: Corten curtain wall systems must be designed to rapidly and completely drain accumulated water.

• Ventilation: A rainscreen system with an air gap behind the curtain wall must be employed. This gap prevents moisture entrapment, allowing the entire surface to dry uniformly—critical for stabilizing the rust patina.

• Avoid Retention: Design details must eliminate recesses, steps, or overlaps where moisture, dirt, or debris could accumulate, creating persistently damp conditions.

Maximum Durability Design Considerations

Initial specifications determine structural lifespan:

• Thickness: Thicker Corten steel plates inherently offer greater durability, as they consume more sacrificial metal before structural failure occurs. Selecting thicker specifications is a key method to maximize Corten steel durability.

• Grade Specifications: Ensure the correct Corten steel grade is selected to meet project load and environmental requirements (e.g., A588 for structural applications or A606-4 for light-duty construction).

Is Corten Steel Cladding Right for Your Project?

Understanding the performance parameters of Corten steel is crucial for successful project planning.

Assessing Project Requirements

When evaluating weathering steel, it is essential to balance budgetary constraints with durability considerations while accounting for aesthetic requirements. If a project demands a service life exceeding 100 years in extreme corrosive environments (such as direct coastal exposure), alternative materials or enhanced coating systems may be necessary. However, for most urban and rural settings, weathering steel still offers superior durability compared to traditional building materials.

Suitable Applications for Weathering Steel

Corten metal cladding should be selected when the following conditions are met:

• Requiring a virtually maintenance-free exterior façade

• Seeking a unique architectural expression that evolves over time

• The project environment ensures sufficient wet-dry cycles

Conclusion: Define Your Architecture with Corten Steel Cladding

A well-detailed and properly installed Corten steel cladding system boasts exceptional longevity, easily achieving 60 to 80 years or more under ideal conditions. The key to this durability lies in a well-designed rainscreen system that ensures rapid drainage and excellent ventilation.

AHL Group provides high-quality Corten steel sheets and custom panels, designed in strict compliance with building codes to ensure the formation of a distinctive protective patina. Investing in such a facade system means it will grow more beautiful and resilient with each passing season.