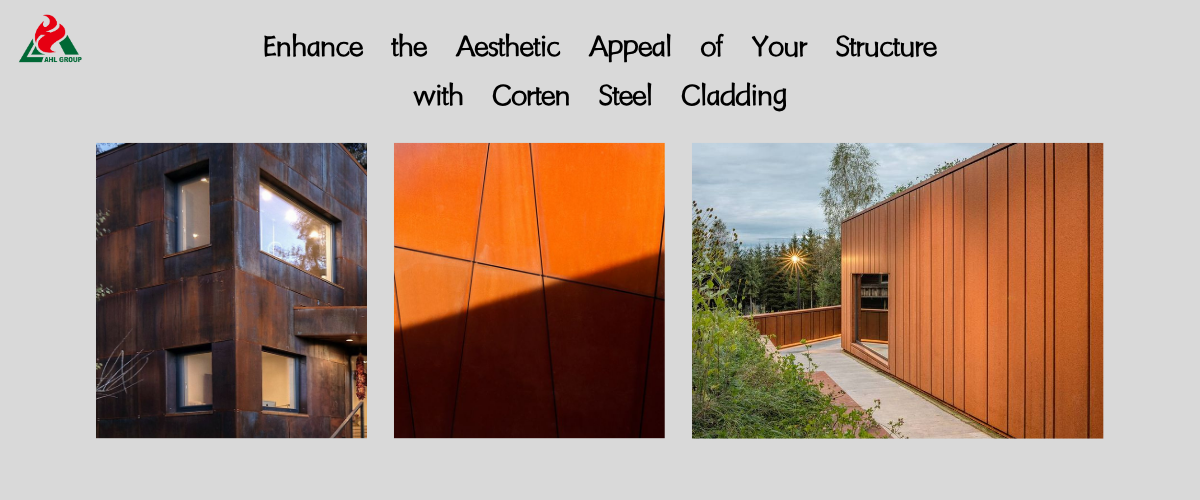

Corten steel cladding is renowned worldwide for its unique aesthetic appeal, but its true performance hinges on technical specifications—most critically, material thickness. When specifying Corten steel curtain walls, selecting the correct thickness determines the panel's structural integrity, wind load resistance, and compatibility with the chosen fixing system.

As a leading manufacturer of weathering steel architectural solutions, AHL Group emphasizes that no single “standard” thickness exists. The required dimensions depend entirely on the specific application, panel size, and environmental stresses the panels will endure. This technical guide breaks down industry guidelines to help you specify the optimal weathering steel thickness for your project.

.png)

As a leading manufacturer of weathering steel architectural solutions, AHL Group emphasizes that no single “standard” thickness exists. The required dimensions depend entirely on the specific application, panel size, and environmental stresses the panels will endure. This technical guide breaks down industry guidelines to help you specify the optimal weathering steel thickness for your project.

.png)

Understanding Corten Steel Cladding Specifications

To make informed decisions, it is essential to understand how material thickness impacts the overall performance and installation outcomes of Corten steel cladding panels.

The Relationship Between Thickness and Performance

Simply put, the thickness of weathering steel directly determines its structural properties. Thicker panels offer greater rigidity, effectively reducing deflection (bending) caused by wind loads or thermal expansion. For large-format panels, insufficient thickness may lead to the “oil drum effect” or poor surface flatness, compromising the building's aesthetic appeal. Thicker specifications also provide more robust connection points for concealed fastening methods.

Industry Standard Measurement and Specification Conversion

In manufacturing and construction, thickness is primarily measured in millimeters (mm), the standard unit for precision processing. However, you may still encounter historical steel specification values. Remember their inverse relationship: lower specification numbers indicate greater steel thickness. When ordering from AHL Group, specify millimeters to ensure maximum precision.

Application-Specific Thickness Guidelines

The specific function of weathering steel—whether purely decorative or as part of a structural rain screen system—determines its minimum required thickness to ensure durability and safety.

Application 1: Decorative Wall Paneling

This application typically involves small to medium-sized panels where weathering steel serves solely as an aesthetic surface layer, without bearing strong wind stresses or structural loads.

Recommended Thickness: 2–3 mm

2 mm thick Corten steel is often the minimum thickness standard for flat, non-structural cladding components. This thickness provides sufficient rigidity for small panels while facilitating bending and forming during custom fabrication. It is ideal when lightweight weathering steel panels are the primary requirement, particularly for interior applications or small decorative elements.

Application 2: Standard Architectural Facades

This category covers most typical residential and commercial curtain wall installations where panels endure conventional wind loads and natural weathering but are mounted on underlying support structures.

Recommended thickness: 3mm–4.5mm

The 3mm to 4mm thickness range is considered the optimal range for most architectural weathering steel applications. This thickness provides the necessary rigidity to maintain flatness in large panels (e.g., 1m × 2m sections) while offering greater cost-effectiveness than thicker plates. At AHL Group, this thickness achieves the optimal balance of structural integrity and aesthetic quality for standard Corten steel siding projects.

Application 3: Structural Rainscreen Curtain Wall Systems

This demanding application involves large-format Corten steel panels, typically used in high-rise buildings or as components of precision-engineered rainscreen curtain wall systems. Complex heavy-duty fixing and support structures are required.

Recommended Thickness: 4.5 mm to 6 mm

For large-format panels, regions with extreme wind loads, or designs requiring deep folds and concealed structural support, 5 mm or 6 mm thick weathering steel is typically selected. This heavy gauge ensures the rigidity necessary for concealed fastening, preventing vibration or displacement from compromising the entire metal cladding system. Choosing thicker material in such scenarios represents an investment in long-term structural resilience.

Thickness vs. Gauge Conversion Chart

To assist in determining material specifications, the following provides a quick conversion guide for common Corten metal cladding thicknesses:

Millimeter to Gauge Equivalent Table

| Corten Thickness (mm) |

Gauge Equivalent (Approx.) | Primary Application |

| 1.5mm |

16 Gauge | Decorative, small edging, low stress |

| 2mm |

14 Gauge | Lightweight cladding panels |

| 3mm |

11 Gauge | Standard facade cladding, general purpose |

| 4.5mm |

8 Gauge | High wind loads, structural returns |

| 6mm |

3 Gauge | Heavy-duty rainscreen, structural support |

How to Interpret Steel Plate Thickness Gauges

The gauge numbers utilize a standardized non-metric measurement system for metal plates. The key point is: the higher the gauge number, the thinner the material. For example, a 16-gauge steel plate (1.5 mm) is significantly thinner than a 3-gauge steel plate (6.0 mm). Always verify the actual thickness in millimeters to avoid costly mistakes in project specifications.

Installation Considerations by Thickness

Thickness selection directly impacts the construction site, affecting panel handling, fastening, and required engineering safeguards.

Fastening Methods for Thin vs. Thick Plates

• Thin plates (≤3mm): Typically rely on exposed fasteners (screws, rivets) or structural adhesives, as material rigidity is insufficient to support complex support systems.

• Thick plates (≥4mm): Easily support precise, adjustable, and concealed fastening systems, achieving a cleaner aesthetic while providing greater adjustment tolerance during installation.

Processing and Manufacturing Requirements

As thickness increases, material weight significantly rises and processing difficulty escalates. 6mm Corten steel panels require precision processing using industrial bending machines and high-power lasers. AHL Group employs specialized heavy-duty equipment to ensure even the thickest materials are manufactured with architectural precision, guaranteeing flawless on-site installation.

Thermal Expansion Calculations

All metal cladding expands and contracts with temperature changes. Thicker panels inherently possess greater rigidity, necessitating precise calculations and design of expansion joints and clearances to prevent deformation or buckling. While thicker panels typically transmit smaller overall displacements, they require stronger anchoring components to withstand the forces they generate.

Frequently Asked Questions About Corten Cladding

Q: Can Thinner Corten Steel Be Used for Curved Surfaces?

Absolutely. Thinner weathering steel (e.g., 1.5 mm to 2 mm) is better suited for creating smooth, continuous curved cladding panels because it requires less force to bend and can accommodate smaller radii of curvature without cracking or deformation.

Q: How Does Thickness Affect Patina Formation?

Thickness does not significantly alter patina quality, which primarily depends on the material's alloy composition (A606-4 standard). However, extremely thick weathering steel plates (e.g., 10 mm structural members) may require longer to develop a complete, stable patina coating due to their increased thermal mass and surface area ratio compared to thinner sheets.

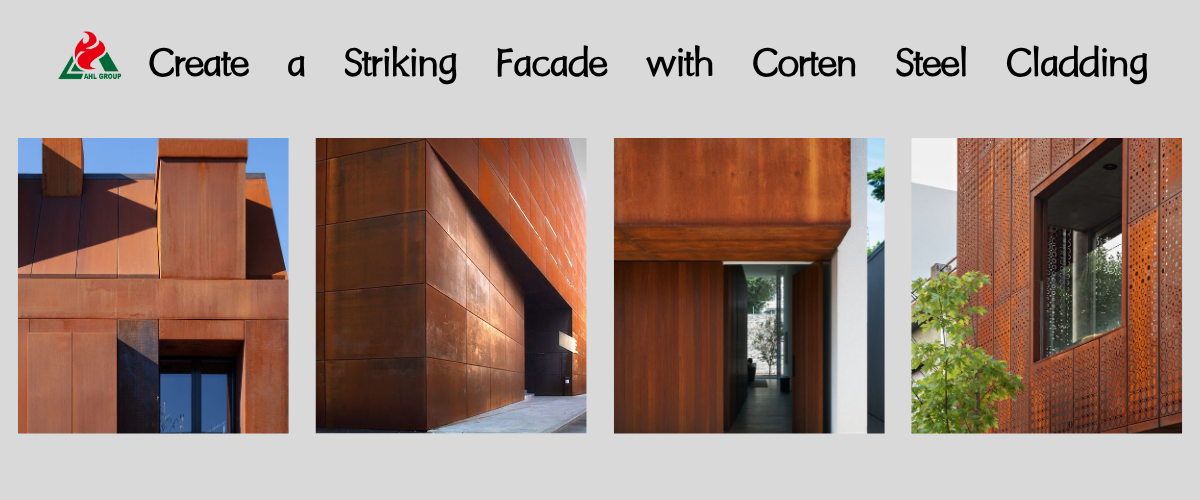

Conclusion: Create a Striking Facade with Corten Steel Cladding

Corten steel panels should be selected based on functional requirements: 2mm thickness suffices for decorative exterior cladding; high-performance curtain walls require 3 to 4mm to achieve an optimal balance between cost and rigidity; while heavy-duty structural rain-screen systems mandate 5mm or greater thickness.

By consulting technical specifications according to application scenarios and sourcing from trusted manufacturers like AHL Group, you can ensure Corten steel cladding meets engineering design requirements for both enduring aesthetics and structural integrity.