1. Introduction: Specifying for Durability and Performance in a New Era

Why Create the 2026 Checklist? Anticipating Trends in Sustainability and Advanced Manufacturing

The specification process is evolving. Beyond basic dimensions, professionals must now consider full-lifecycle environmental impact, embedded carbon footprint, and digital twin integration. This 2026 List aims to merge emerging demands with uncompromising engineering fundamentals, ensuring your specified planting containers meet both current and future standards for public, commercial, and high-end residential projects—delivering future-proofing for your projects.

Objective: Safeguarding Project Durability, Safety, and Aesthetic Integrity

Improperly specified outdoor planters can lead to premature damage, safety hazards, or unsightly staining. This guide eliminates guesswork. By systematically checking every project element—from metal materials to installation points—you achieve durable, low-maintenance installations. Their surfaces develop an attractive, stable patina, while structural performance endures for decades, protecting your design intent and your client's investment.

2. Core Material & Metallurgical Specifications

Steel Grades and Standards: ASTM A588 Corten-A vs. EN 10025-5 S355J2W+AR

The base material is critical. Please confirm the use of genuine weathering steel.

► Primary Standard (Americas/Asia): ASTM A588 Grade A or Grade B. This standard specifies minimum yield strength (345 MPa / 50 ksi), tensile strength, and key alloying elements (Cu, Cr, Ni, P) that promote rust layer formation.

► Primary Standard (Europe/UK): EN 10025-5, Grade S355J2W or S355J0W. The letter “W” denotes atmospheric corrosion resistance. Specify the “+AR” (as-rolled) delivery condition; coated surface treatments are not permitted.

► Specification Clause: The landscape planter body shall be fabricated from authentic weathering steel certified to ASTM A588 or EN 10025-5. A Mill Test Certificate (MTC) must be provided for each batch.

Minimum Thickness (Specifications): Floor Panels, Side Walls, and Structural Reinforcements

Thickness directly impacts service life and dent resistance.

► Standard/Residential Grade: Side Walls: Minimum 3.0 mm. Floor Panels: Minimum 4.0 mm.

► Commercial/Heavy-Duty/Extra-Large (Single-Side Dimension > 1.5m): Sidewalls: 4.0-6.0mm. Bottom Panel: 5.0-8.0mm (requires internal stiffeners or support structures).

► Specification Clause: Material thickness shall be determined based on structural calculations to meet anticipated load and application requirements, with a minimum sidewall thickness of 3mm and a minimum bottom panel thickness of 4mm.

Material Certification: Requirement for Mill Test Certificates (MTC)

Steel mill test certificates (MTC) must be provided. General “material certificates” are not accepted. Steel producers must supply batch-specific mill test certificates detailing actual chemical composition and mechanical properties to verify compliance with weathering steel specifications.

Pre-weathering and Natural Rusting Treatment Solutions: Technical Definition

Clearly define the required surface treatment effect.

► Natural Rust Layer: Steel shall be delivered in the rolled scale condition. The rust layer will form naturally on-site over a period of 18-36 months.

► Pre-oxidation Treatment: Steel shall undergo chemical treatment before shipment to form a stable, uniform rust layer. All components must exhibit consistent surface treatment results with no loose residues.

3. Design, Fabrication & Construction Checklist

Welding Standard: Continuous, Full-Penetration Welds

Corners and joints represent potential failure points.

► Requirement: All structural joints (corner joints, base plate-to-side wall connections) must employ continuous, full-penetration welds.

► Surface Treatment: All external surfaces of welded areas must be ground smooth and level to ensure safety and uniform patina formation. Internal welds shall remain clean and free of spatter.

Structural Integrity: Internal Bracing Requirements

For any garden planter with an internal soil height exceeding 60cm or a length/width over 1.2m, internal structural bracing is mandatory to resist soil pressure and prevent bulging.

► Manufacturing Tolerances: Squareness, Dimensions, and Panel Alignment

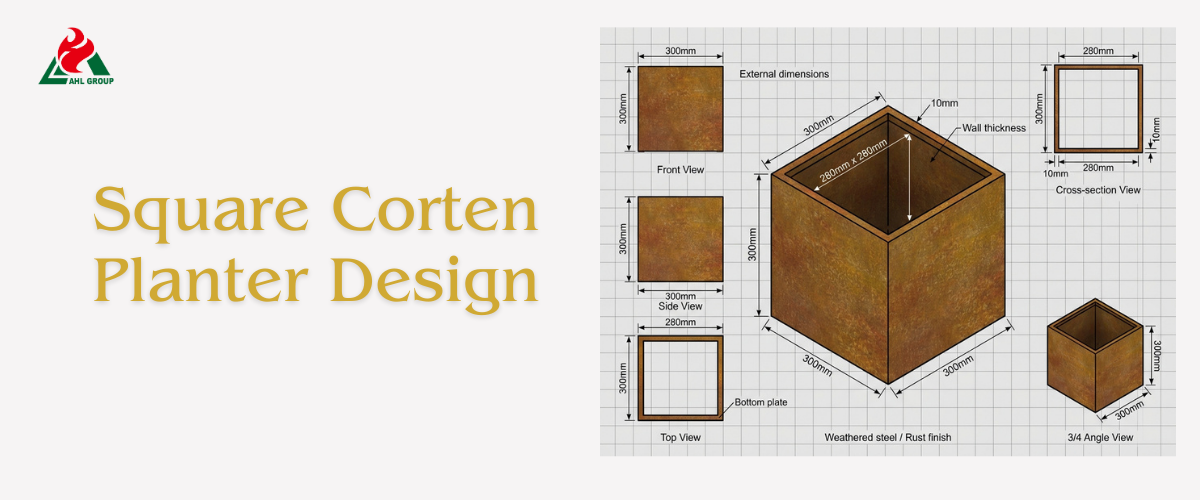

► Dimension Tolerance: Overall Length/Width/Height: ±2.0 mm.

► Squareness Tolerance: Diagonal Difference: ≤3.0 mm.

► Specification Clause: Manufacturing dimensions must strictly conform to requirements, with maximum deviations as stated above. All panels shall exhibit no noticeable step-like misalignment or displacement.

Edge Treatment: Rolled or Polished Smooth Edge Specifications

To ensure safety and premium aesthetics, all top edges must be deburred and polished smooth.

► Requirements: The rolled edge (edge wrapping) process is preferred for enhanced safety and rigidity. Minimum requirement: All cut edges must be polished to a smooth, safe radius (minimum R2mm).

4. Drainage, Waterproofing & Root Management System

Drainage Hole Configuration: Quantity, Size, Position

Poor drainage is the primary cause of planter and plant failure.

► Hole Diameter: Minimum diameter of 10-12 mm.

► Quantity and Layout: At least one drainage hole per 0.1 square meters of base area, evenly distributed. Drainage holes in linear planters should be arranged along the centerline.

Compatibility with Integrated Reservoirs or French Drain Systems

Suitable for premium horticulture or installations requiring water control.

► Option A (Built-in Reservoir): Corten planters must incorporate a false bottom/water collection tray system to create a separate reservoir zone, featuring an operable overflow outlet and optional integrated water level indicator.

► Option B (External Drainage): Flower pot bases must be compatible with underground French drainage systems via pre-installed drainage sleeves.

Optional Lining or Coating

Suitable for growing acid-loving plants (such as azaleas) or scenarios requiring enhanced root protection.

► Requirement: Suppliers must apply a continuous food-grade/solvent-free asphalt or epoxy coating to the entire inner surface of the container (including weld seams).

5. Load-Bearing, Safety & Compliance Specifications

Seismic/Wind Load Considerations for Public Spaces

Flower pots on rooftops, elevated balconies, or public plazas are classified as non-structural components of buildings.

► Code Provision: In seismic zones, planter box designs and anchoring details must be reviewed by the project structural engineer, accounting for saturated soil weight and overturning moments.

Factory-Applied Anti-Graffiti Coating (Optional)

Applicable for public or transit-oriented projects at risk of vandalism.

► Requirements: Exterior surfaces shall be coated with a permanent, transparent, UV-resistant coating (e.g., fluoropolymer or ceramic-based). This coating shall not impede natural rust formation and must permit the removal of graffiti using standard mild solvents without causing damage.

6. Surface Finish & Patina Performance Guarantees

Timeline for Patina Formation and Stability Definition

Manage client expectations through contract terms.

► Specification Clause (Natural): Patina formation is a natural process. Initial orange-brown bleeding may persist for 6-12 months. Under typical cyclic climate conditions, stable, dark patina adhesion is expected to develop within 18-24 months.

Acceptable Color Variation and Environmental Performance

► Color Variation: The natural rust layer will create unique color variations on the surface, which is an inherent characteristic of the material rather than a defect.

► Corrosion Category: Confirm the steel meets the project's ISO 12944 corrosion category requirements (e.g., C3 for urban/industrial environments, C4 for coastal environments).

7. Logistics, Packaging & Installation

Packaging Standards: Weatherproof, Stackable

To prevent damage and staining during ocean or land transport.

Requirements: Each planter pot must be individually wrapped in breathable, stain-resistant protective material (e.g., VCI rust-proof paper, non-woven fabric). Products shall be packed in wooden crates or secured on wooden pallets in a stackable configuration to prevent shifting and physical damage.

Lifting and Anchoring Points

Ensure secure installation of heavy fixtures.

Requirements: Pots exceeding 150 kg (330 lbs) empty weight must be equipped with four integral reinforced lifting sockets or lifting lugs. For permanent installations in public areas, provide standard detailing for galvanized steel anchor straps or through bolts securing to the base structure.

8. Global Compliance & Sustainability Metrics (A 2026 Focus)

Regional Material Compliance

► EU and UK: Provide CE certification/UKCA certification in accordance with Construction Products Regulation (CPR) requirements, accompanied by a Declaration of Performance (DoP).

► North America: Commercial furniture products must comply with relevant ANSI/BIFMA standards (where applicable).

Environmental Product Declaration (EPD) Data

Leading requirements for green building certifications (LEED, BREEAM, Green Star).

► Specification Clause: Manufacturers must provide third-party verified Type III Environmental Product Declarations (EPDs) detailing Global Warming Potential (GWP), recycled material content, and end-of-life disposal solutions.

Logistics Carbon Footprint Estimation

► Requirement: Suppliers must provide estimated product carbon footprint values (in kilograms of carbon dioxide equivalent) covering the cradle-to-factory-gate phase (A1-A3) and transportation to the designated project destination port (A4).

Conclusion: Best Practices for Selecting Corten Planters

Eliminate specification development burdens. AHL Group provides pre-certified technical data packages, detailed BIM objects, and structural calculation summaries for every significant quotation. Our in-house engineering team collaborates directly with your project team to customize specifications, ensuring every requirement on this 2026 list is not only met but exceeded.

【Contact our technical specifications team today to receive a customized specification sheet and certified samples for your project.】