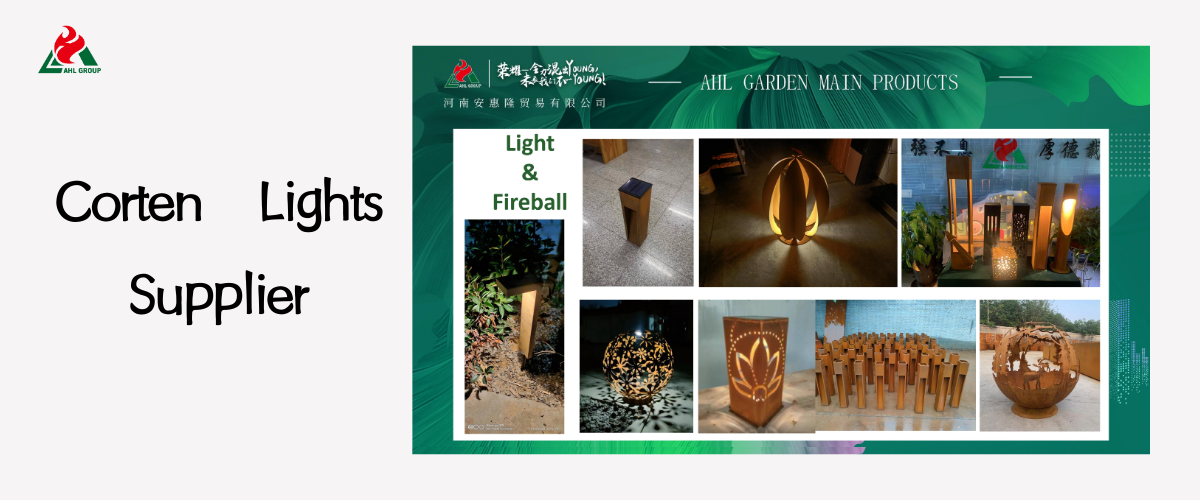

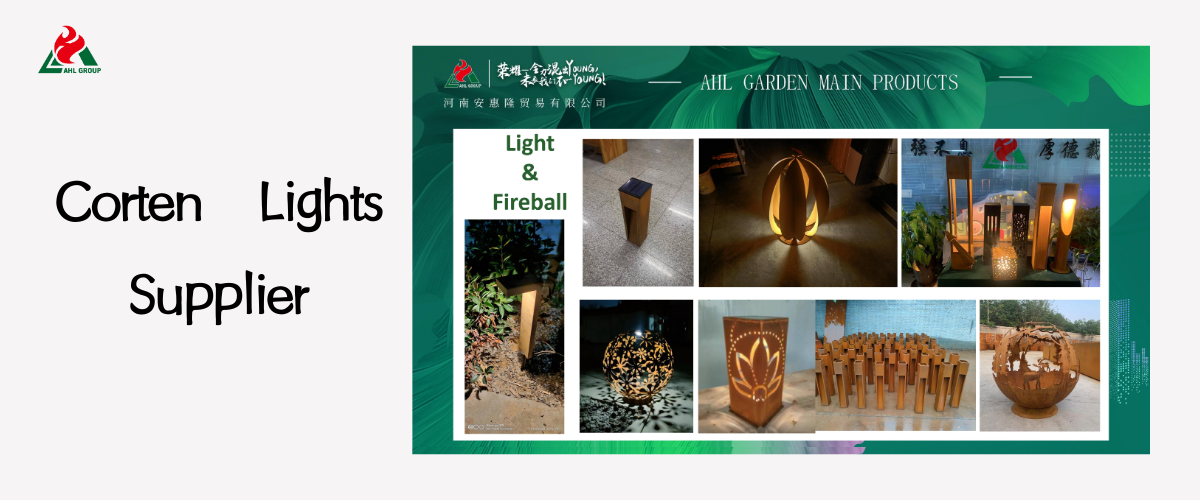

The initial price tag for Corten steel lighting or fixtures is often significantly higher than that of low-carbon steel or aluminum products. This price difference frequently raises the question: Is this investment worthwhile? AHL Group believes this price difference fundamentally reflects the significant gap in material science, manufacturing processes, and product longevity. This guide goes beyond the price tag to delve into Total Cost of Ownership (TCO), demonstrating why AHL Corten outdoor lighting represents the most forward-thinking long-term investment choice for commercial and high-end residential landscapes.

The seemingly high cost of Corten steel is not a matter of profit, but rather an inevitable result of its exceptional alloy properties and zero-maintenance promise.

When purchasing AHL Corten lighting, you are paying for the alloy elements that impart self-protective properties to the material—specifically copper, chromium, and nickel. This investment ensures the product continuously develops a durable, aesthetically unique surface (patina) that permanently eliminates the need for painting, sealing, or galvanizing. The higher initial cost is a one-time expense, yielding 25 years of maintenance-free, self-finishing material.

“Cheap” low-carbon steel fixtures require regular maintenance to prevent catastrophic structural corrosion. Hidden costs include: ongoing expenses for high-quality protective coatings (paint or powder coating), labor costs for pre-treatment and re-spraying every 5 to 7 years, and inevitable replacement costs when weak protective layers fail, leading to deep corrosion that compromises fixture integrity. The true total cost of ownership for cheap fixtures depends on their replacement cycle.

Four key factors are driving the higher manufacturing costs of genuine Corten steel lighting products.

The fundamental difference begins at the procurement stage. Ordinary carbon steel (the primary component of low-cost alternatives) is a commodity material, whereas weathering steel is a specialty product manufactured through precise control of alloy additions.

The high-grade alloys (primarily copper, chromium, and nickel) required to form the protective rust layer elevate the base material cost of weathering steel plates to two to three times that of ordinary steel. This substantial material cost is non-negotiable, as these elements are crucial for forming the dense, adherent oxide layer that prevents further corrosion.

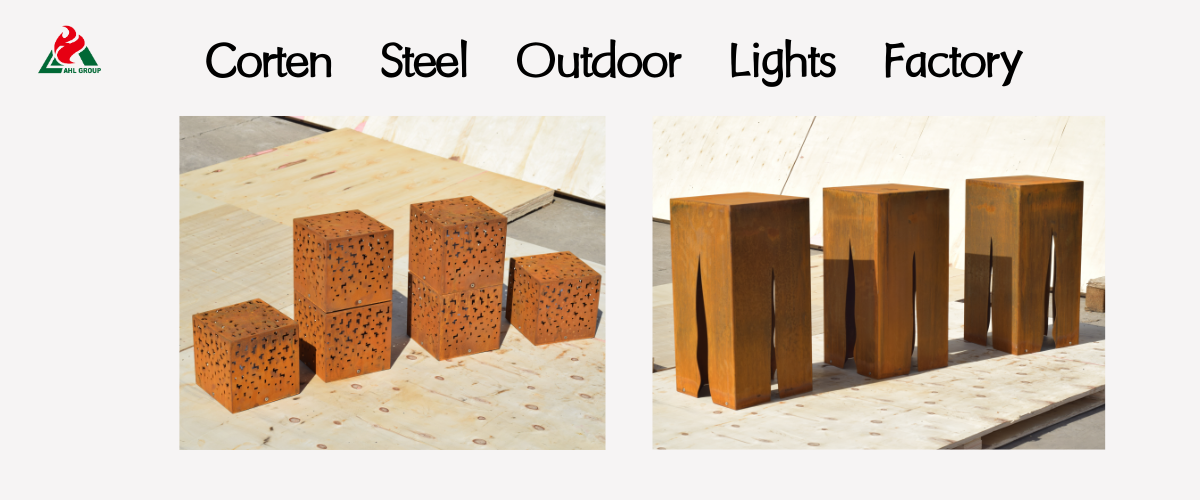

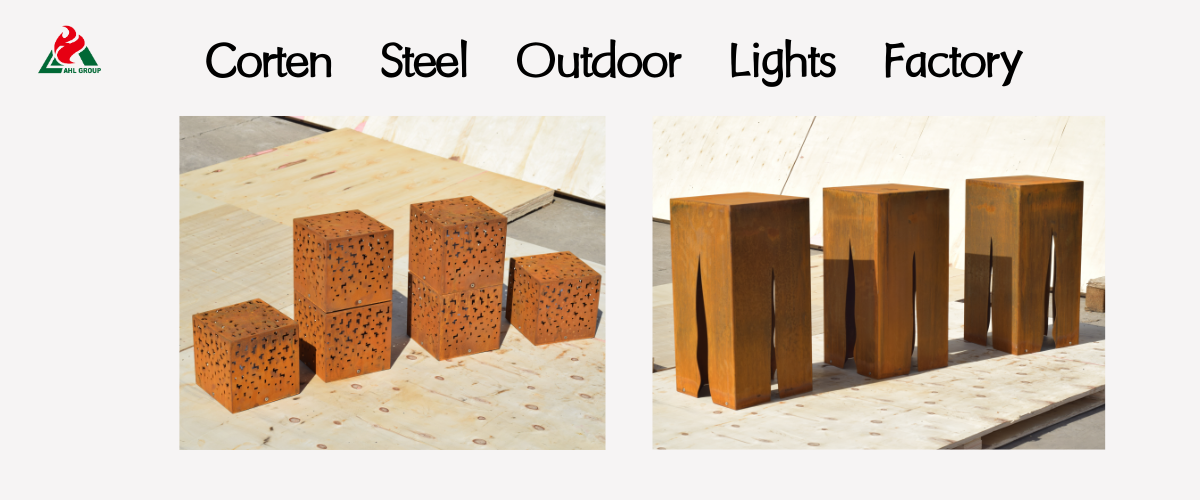

Processing weathering steel requires specialized expertise and dedicated equipment, increasing production costs compared to conventional metal fabrication.

Weathering steel processing—particularly for precision products like AHL outdoor lighting fixtures—must be strictly segregated from other carbon steels and stainless steels. Contamination by non-weathering steel particles can cause localized corrosion failure points on the finished weathering steel surface. This requirement compels manufacturers to invest in specialized equipment and hire highly skilled workers to ensure contamination-free welding and cutting processes, thereby increasing per-unit costs.

The final surface of weathering steel is its natural state, eliminating specific processing costs while fully leveraging its premium material properties.

Inexpensive lighting fixtures require chemical pretreatment, primer application, and multiple layers of paint or powder coating—constituting significant manufacturing costs. Weathering steel bypasses these steps. While its material cost exceeds that of coated standard steel, the key advantage lies in its natural rust patina serving as a permanent surface treatment, eliminating all future refurbishment expenses.

Weathering steel's durability shifts financial considerations from short-term procurement to long-term asset investment.

AHL Corten steel lights are engineered for over 25 years of service without structural maintenance. Conversely, powder-coated low-carbon steel or poorly finished aluminum fixtures typically require complete replacement every 5 to 10 years when coating failure leads to substrate corrosion. Over two decades, the same location might require four replacements of inexpensive fixtures, whereas a single purchase of durable weathering steel lights demonstrates significant cost-effectiveness.

To make an accurate comparison, costs must be discounted over the product's expected service life.

The initial investment cost for high-quality AHL Corten lights may be 150% to 300% higher than that of standard steel luminaires of equivalent specifications. This price difference represents the premium paid for premium raw materials and specialized manufacturing processes—the very elements that ensure the garden lamps' long-term performance.

Weathering steel is widely recognized by architects and appraisers as a high-quality, permanent, and distinctive building material. Selecting AHL Corten landscape lighting enhances a property's overall aesthetic value and positively impacts asset valuation—a return on investment unattainable with cheap, inferior lighting fixtures.

When applications demand durability and low lifecycle costs, the premium cost of Corten steel proves to be a worthwhile investment.

For fixed, highly visible, and non-removable landscape elements—such as integrated wall lighting or pathway bollards—that will remain integral to the landscape for decades, the initial investment in AHL Corten steel minimizes future disruptive maintenance.

In projects where aesthetic consistency and material integrity are paramount—such as public monuments, corporate headquarters, or luxury residential facades—Corten steel's distinctive patina delivers a design statement that transcends initial cost considerations.

In salt-spray eroded coastal zones or heavily polluted industrial areas, conventional coatings rapidly fail. Weathering steel's specialized alloy composition is engineered to withstand harsh environments, making it the most resilient and cost-effective solution over its entire lifecycle.

Ensuring your investment delivers genuine value requires vigilance.

When comparing quotes, assess material thickness, the quality of internal lighting components, and welding techniques. Inexpensive weathering steel lamps may use thin-gauge materials, compromising structural integrity—a false economy. AHL Group maintains stringent standards for metal thickness and component quality.

Beware of ordinary low-carbon steel products merely coated with brown powder spray, yet marketed as “weathering steel appearance.” Authentic weathering steel should be delivered with a smooth, dense dark gray surface that naturally rusts when exposed to air. Always request material certification from suppliers to ensure you are purchasing genuine weathering steel.

The investment value of AHL Corten steel lighting is realized through the elimination of all repainting and replacement costs. It offers a maintenance-free aesthetic solution, becoming the most cost-effective choice over the project's entire lifecycle.

Yes, but trade-offs apply. You can opt for aluminum components finished with a weathering steel-effect powder coating. This solution reduces upfront costs and avoids rust seepage, but the coating surface will still require maintenance or replacement after 10-15 years due to fading and chalking.

Absolutely. Price variations directly correlate with raw material quality (specialty alloys vs. standard steel) and the specialized manufacturing processes required to safely process authentic weathering steel.

Galvanized steel offers moderate longevity (15-20 years) but lacks the distinctive rust patina of weathering steel. High-quality aluminum combines durability with lightweight advantages, yet requires powder coating for coloration and cannot replicate the organic texture formed by weathering steel's rust process.

The initial cost of AHL Corten metal lighting represents an investment in timeless, durable, and zero-maintenance architecture. When shifting focus from purchase price to 25-year total cost of ownership, weathering steel emerges not only as a premium aesthetic choice but also as the economical solution for projects seeking enduring vitality and lasting beauty. Select AHL Group-certified high-quality weathering steel lighting to create timeless classics that stand the test of time.

The Price Difference Reality Check

The seemingly high cost of Corten steel is not a matter of profit, but rather an inevitable result of its exceptional alloy properties and zero-maintenance promise.

The True Value of Corten Lighting

When purchasing AHL Corten lighting, you are paying for the alloy elements that impart self-protective properties to the material—specifically copper, chromium, and nickel. This investment ensures the product continuously develops a durable, aesthetically unique surface (patina) that permanently eliminates the need for painting, sealing, or galvanizing. The higher initial cost is a one-time expense, yielding 25 years of maintenance-free, self-finishing material.

The Hidden Costs of “Cheap” Alternatives

“Cheap” low-carbon steel fixtures require regular maintenance to prevent catastrophic structural corrosion. Hidden costs include: ongoing expenses for high-quality protective coatings (paint or powder coating), labor costs for pre-treatment and re-spraying every 5 to 7 years, and inevitable replacement costs when weak protective layers fail, leading to deep corrosion that compromises fixture integrity. The true total cost of ownership for cheap fixtures depends on their replacement cycle.

Detailed Cost Analysis of Corten Lights

Four key factors are driving the higher manufacturing costs of genuine Corten steel lighting products.

Cost Factor 1: Raw Material Pricing

The fundamental difference begins at the procurement stage. Ordinary carbon steel (the primary component of low-cost alternatives) is a commodity material, whereas weathering steel is a specialty product manufactured through precise control of alloy additions.

Weathering steel costs 2-3 times more than ordinary steel

The high-grade alloys (primarily copper, chromium, and nickel) required to form the protective rust layer elevate the base material cost of weathering steel plates to two to three times that of ordinary steel. This substantial material cost is non-negotiable, as these elements are crucial for forming the dense, adherent oxide layer that prevents further corrosion.

Cost Factor 2: Manufacturing Complexity

Processing weathering steel requires specialized expertise and dedicated equipment, increasing production costs compared to conventional metal fabrication.

Dedicated Equipment and Skilled Labor Requirements

Weathering steel processing—particularly for precision products like AHL outdoor lighting fixtures—must be strictly segregated from other carbon steels and stainless steels. Contamination by non-weathering steel particles can cause localized corrosion failure points on the finished weathering steel surface. This requirement compels manufacturers to invest in specialized equipment and hire highly skilled workers to ensure contamination-free welding and cutting processes, thereby increasing per-unit costs.

Cost Factor 3: Surface Treatment

The final surface of weathering steel is its natural state, eliminating specific processing costs while fully leveraging its premium material properties.

Natural Rust Patina vs. Paint/Powder Coating

Inexpensive lighting fixtures require chemical pretreatment, primer application, and multiple layers of paint or powder coating—constituting significant manufacturing costs. Weathering steel bypasses these steps. While its material cost exceeds that of coated standard steel, the key advantage lies in its natural rust patina serving as a permanent surface treatment, eliminating all future refurbishment expenses.

Cost Factor 4: Product Lifespan

Weathering steel's durability shifts financial considerations from short-term procurement to long-term asset investment.

25+ Year Service Life VS. 5-10 Year Replacement Cycle

AHL Corten steel lights are engineered for over 25 years of service without structural maintenance. Conversely, powder-coated low-carbon steel or poorly finished aluminum fixtures typically require complete replacement every 5 to 10 years when coating failure leads to substrate corrosion. Over two decades, the same location might require four replacements of inexpensive fixtures, whereas a single purchase of durable weathering steel lights demonstrates significant cost-effectiveness.

The True Cost of Ownership Comparison

To make an accurate comparison, costs must be discounted over the product's expected service life.

Initial Purchase Price Analysis

The initial investment cost for high-quality AHL Corten lights may be 150% to 300% higher than that of standard steel luminaires of equivalent specifications. This price difference represents the premium paid for premium raw materials and specialized manufacturing processes—the very elements that ensure the garden lamps' long-term performance.

Maintenance and Replacement Costs Over 20 Years

| Cost Factor |

Corten Steel Fixture (20 Years) | Mild Steel Fixture (20 Years) |

| Initial Purchase |

100% (One time) | 25%(Four Times) |

| Maintenance (Repainting/Sealing) |

0% | 50%(Labor + Materials) |

| Replacement (3 cycles total) |

0% | 75%(Fixtures + Labor) |

| Total 20-Year Cost |

100% | 150% to 200% |

Property Value Impact and Aesthetic Appeal

Weathering steel is widely recognized by architects and appraisers as a high-quality, permanent, and distinctive building material. Selecting AHL Corten landscape lighting enhances a property's overall aesthetic value and positively impacts asset valuation—a return on investment unattainable with cheap, inferior lighting fixtures.

When Corten is Worth the Investment

When applications demand durability and low lifecycle costs, the premium cost of Corten steel proves to be a worthwhile investment.

Permanent Landscape Installations

For fixed, highly visible, and non-removable landscape elements—such as integrated wall lighting or pathway bollards—that will remain integral to the landscape for decades, the initial investment in AHL Corten steel minimizes future disruptive maintenance.

High-Visibility & Architectural Applications

In projects where aesthetic consistency and material integrity are paramount—such as public monuments, corporate headquarters, or luxury residential facades—Corten steel's distinctive patina delivers a design statement that transcends initial cost considerations.

Coastal or Harsh Environments

In salt-spray eroded coastal zones or heavily polluted industrial areas, conventional coatings rapidly fail. Weathering steel's specialized alloy composition is engineered to withstand harsh environments, making it the most resilient and cost-effective solution over its entire lifecycle.

Making Smart Purchase Decisions

Ensuring your investment delivers genuine value requires vigilance.

Evaluate Quality vs. Price Trade-offs

When comparing quotes, assess material thickness, the quality of internal lighting components, and welding techniques. Inexpensive weathering steel lamps may use thin-gauge materials, compromising structural integrity—a false economy. AHL Group maintains stringent standards for metal thickness and component quality.

Distinguishing Genuine Weathering Steel from Imitations

Beware of ordinary low-carbon steel products merely coated with brown powder spray, yet marketed as “weathering steel appearance.” Authentic weathering steel should be delivered with a smooth, dense dark gray surface that naturally rusts when exposed to air. Always request material certification from suppliers to ensure you are purchasing genuine weathering steel.

Return on Investment and Long-Term Value

The investment value of AHL Corten steel lighting is realized through the elimination of all repainting and replacement costs. It offers a maintenance-free aesthetic solution, becoming the most cost-effective choice over the project's entire lifecycle.

Frequently Asked Questions About Corten Steel Lights

Q: Can I Get the Same Look at a Lower Cost?

Yes, but trade-offs apply. You can opt for aluminum components finished with a weathering steel-effect powder coating. This solution reduces upfront costs and avoids rust seepage, but the coating surface will still require maintenance or replacement after 10-15 years due to fading and chalking.

Q: Does Price Difference Reflect Quality Difference?

Absolutely. Price variations directly correlate with raw material quality (specialty alloys vs. standard steel) and the specialized manufacturing processes required to safely process authentic weathering steel.

Q: Are There Mid-Range Alternatives?

Galvanized steel offers moderate longevity (15-20 years) but lacks the distinctive rust patina of weathering steel. High-quality aluminum combines durability with lightweight advantages, yet requires powder coating for coloration and cannot replicate the organic texture formed by weathering steel's rust process.

Conclusion: Illuminate Your Garden with Corten Steel Courtyard Lights

The initial cost of AHL Corten metal lighting represents an investment in timeless, durable, and zero-maintenance architecture. When shifting focus from purchase price to 25-year total cost of ownership, weathering steel emerges not only as a premium aesthetic choice but also as the economical solution for projects seeking enduring vitality and lasting beauty. Select AHL Group-certified high-quality weathering steel lighting to create timeless classics that stand the test of time.