In modern landscape architecture, the shift from rigid linear geometries to fluid organic forms has revolutionized garden design. Corten steel garden edging has emerged as the material of choice for such designs, owing to its unique combination of structural strength and remarkable ductility. AHL Group specializes in providing high-quality weathering steel, empowering designers to push the boundaries of form.

This guide delves into the technical challenges and professional solutions for achieving perfect curves, ensuring your garden borders remain structurally sound while delivering visual excellence.

This guide delves into the technical challenges and professional solutions for achieving perfect curves, ensuring your garden borders remain structurally sound while delivering visual excellence.

The Design Challenge: Curves vs. Straight Lines

The transition from straight lines to curves induces physical stress in metal, requiring careful handling to maintain the integrity of the boundary.

The Allure of Curved Garden Borders

Curves mimic the natural flow of the environment, softening transitions between hardscape and softscape elements. Thoughtfully designed curves guide the eye through the landscape, creating a sense of depth in compact gardens while providing an elegant frame for premium plants.

Comprehending the Flexibility and Limitations of Corten Steel

Though a high-strength alloy, Corten steel's “bendability” is determined by its thickness (gauge). Edging between 1.5mm and 3mm offers exceptional flexibility, while thicker plates require mechanical assistance. Mastering the “yield point”—the critical threshold where steel holds its new shape without springing back—is the core skill of professional installation.

The Two Main Approaches to Curves

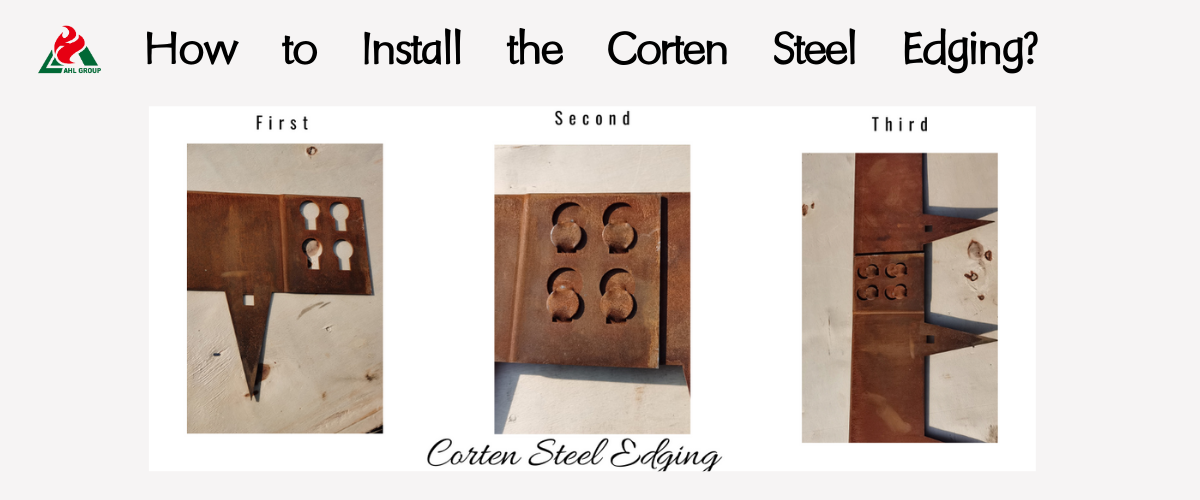

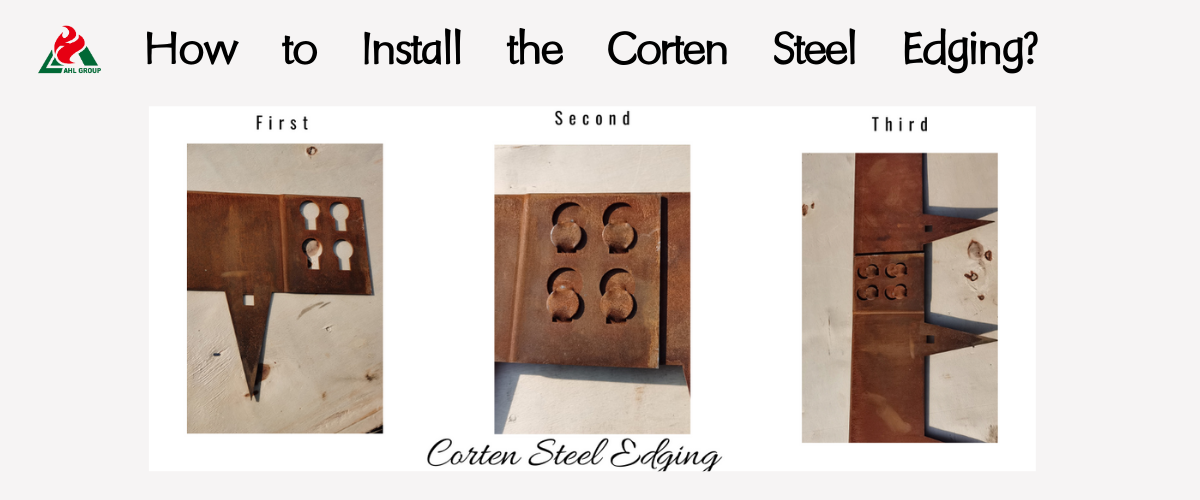

When designing a project with AHL Group Corten edging, you must decide between manual manipulation on-site or factory-level precision.

Approach 1: Field Bending (DIY)

On-site bending involves shaping steel directly in the garden during installation.

Pros: Cost-effective and Customizable on-site

This method offers high flexibility. Should decisions arise mid-installation to widen paths or adjust flower beds, steel can be immediately adapted to new ground contours. No need for precise CAD drawings before project commencement.

Cons: Labor-intensive and Requires Specialized Skills

On-site bending demands physical strength and precise judgment. Without proper support measures, it easily creates “flat spots” instead of smooth, continuous curves. Additionally, achieving perfectly consistent bends across multiple garden areas is significantly more challenging.

Approach 2: Pre-Fabricated Curves

For projects requiring geometric precision, AHL Group offers prefabricated components rolled to specific radii.

Pros: Perfectly Consistent Curves and Clean Aesthetics

Factory-rolled curves achieve far greater precision than manual bending. For applications like circular herb gardens, tree rings, or formal emblems, even a 1-inch deviation becomes visible to the naked eye—making this accuracy critical.

Cons: Higher Cost and Limited Design Flexibility

Precast components incur higher costs due to specialized rolling equipment. Their design must be strictly fixed; if on-site measurements deviate by just a few degrees, pre-bent steel may not fit directly into grooves and require significant modification for adaptation.

.png)

Techniques for Successful Field Bending

When opting to bend AHL Group Corten landscape edging strips on-site, follow these professional techniques to avoid common mistakes.

Use Jigs or Templates to Ensure Consistency

Never bend “freehand.” Create a template on the ground using plywood or heavy timber stakes driven into the ground. By pressing the steel against a stable, solid surface, you ensure that bending forces are evenly distributed along the entire length of the edging strip.

(Caution) Heat Steel for Tighter Bends

For extremely tight radii, professional installers may lightly heat the “bend zone” with a torch. This reduces internal alloy stresses. Proceed with extreme caution to avoid altering the chemical properties necessary for forming the protective patina.

Prevent Twisting, Warping, and Patina Damage

“Twisting” occurs when force concentrates at a single point. Avoid this by applying long, steady pressure rather than abrupt pulling. If warping appears at the top edge of the steel, the bending radius is too tight for that specific steel thickness.

Professional Tips for Seamless Curves

Achieving a curve is one thing; making it look seamless on a 50-meter track is another.

Gardener's Secret: Use Multiple Short Edging Strips

For complex, winding paths, shorter edging strips (e.g., 1.5-meter lengths) are often easier to install than 3-meter lengths. Shorter sections bend more easily and allow for more anchor points, helping the steel maintain its shape under soil pressure.

The Importance of a Perfectly Curved Trench Base

Steel bends along the path of least resistance. If the trench edges are uneven, the curve will distort. Mark a smooth path using a garden hose or spray paint line, then excavate a trench slightly wider than the steel for precise adjustments.

Concealing Seams in Curved Sections

Seams are most visible at bends. AHL Group recommends positioning seams at “inflection points”—where the curve changes direction (e.g., transitioning from left to right turn). This location experiences minimal tensile stress on the steel.

Troubleshooting Common Curve Problems

The Edging “Springs Back” or Won't Hold the Curve

This occurs when the steel remains within its elastic limit. The material must be slightly “overbent” beyond the target shape so that upon release, it precisely settles to the desired radius.

Noticeable Creases or Folds at the Inside Bend

This typically happens on the “inside” of extremely tight curves where the metal has nowhere to expand. The solution is to use thinner weathering steel plates or increase the bending radius.

Peeling of Rust Layer at Bending Points

If pre-weathered steel is bent, the surface oxide scale may peel off. This is normal. Within weeks, the steel will naturally re-oxidize and self-repair, ultimately forming a uniform surface finish.

Inspiration and Design Ideas

Crafting Fluid Lawn Curves and Winding Pathways

Graceful S-curves are a hallmark of premium English and Japanese gardens. They evoke an air of mystery, as the full path remains hidden from view.

Circular Herb Gardens and Crest Flowerbeds

Using AHL Group tree rings or custom curved components, perfect concentric circles can be created, serving as elegant focal points within the courtyard.

Wavy Patterns and Organic Free Forms

The strength of weathering steel supports “wave” designs—boundary heights that vary along the curve, forming three-dimensional sculptural effects that undulate with the terrain.

Frequently Asked Questions About Corten Edging

Q: What's the Tightest Radius Possible with Standard 6" Edging?

For 3mm-thick garden edging, a 1-meter radius can be easily achieved with on-site bending. Smaller radii (e.g., 30cm) typically require mechanical bending machines or factory pre-fabrication.

Q: Can I Bend Edging Myself, or Do I Need a Fabricator?

Most residential projects (curved paths, flower beds) can be completed with basic tools. However, retaining walls for commercial structures are recommended to be processed by professional manufacturers.

Q: Will Bending It Weaken or Compromise the Steel?

No. Weathering steel is specifically designed for structural applications. The cold-forming process actually slightly increases the hardness of the steel at the bend points without affecting its corrosion resistance.

Conclusion: The Art of the Curve in Landscape Edging

The allure of curved Corten steel borders lies in their paradox: this rigid industrial material flows like water through gardens. By mastering on-site bending techniques and understanding the structural limits of steel, you can transform simple borders into architectural artworks.

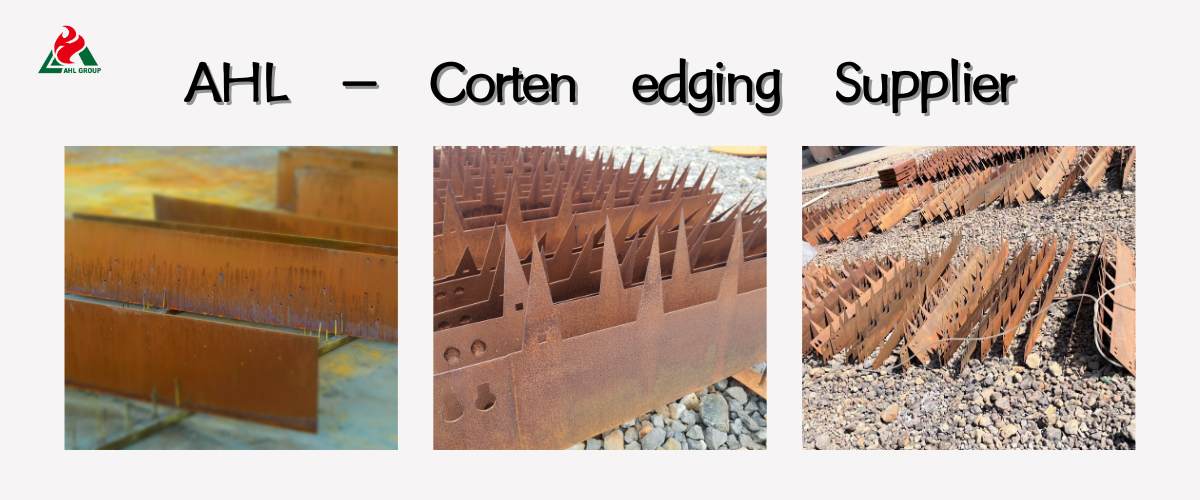

AHL Group provides premium weathering steel and technical support to help you realize your most ambitious organic designs. Whether laying clean lawn curves or crafting meandering pathways, our steel ensures your vision stands the test of time.