In the realm of high-end landscape architecture, selecting the right lighting solution involves more than just brightness—it requires a comprehensive evaluation of durability, material properties, and structural integrity. AHL Group frequently receives inquiries about the price difference between premium Corten lights and mainstream aluminum alternatives. This guide delves into the economic and engineering drivers behind these costs, empowering you to make informed investment decisions for your next project.

.png)

.png)

Understanding the Price Difference in Outdoor Lighting

When browsing professional lighting catalogs, the price disparity between Corten steel bollard lights and aluminum poles is often staggering. To understand this difference, one must look beyond the initial price tag and delve into the underlying market positioning.

The Premium vs. Mainstream Lighting Market

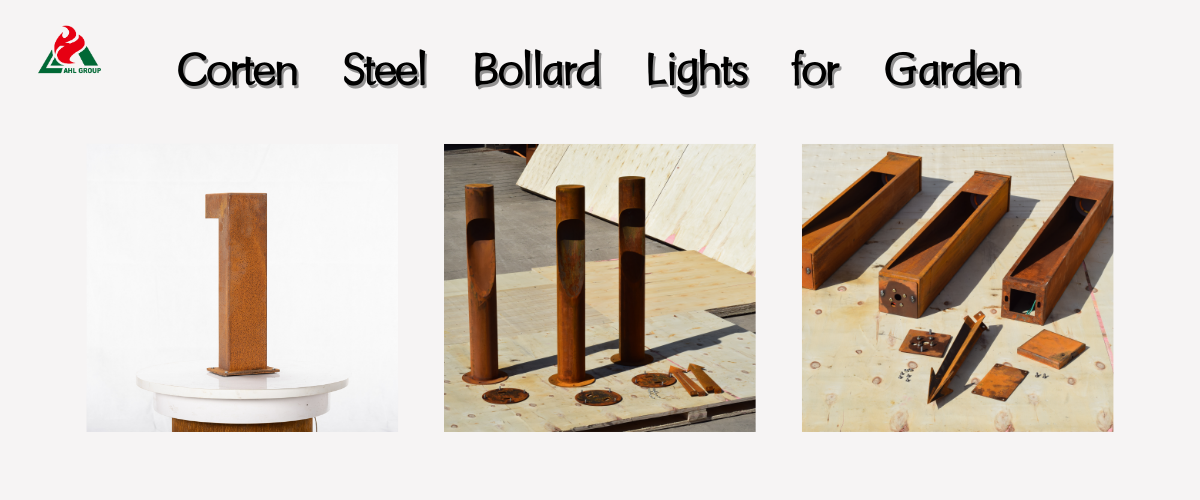

The outdoor lighting industry exhibits a dual-track divergence. The “mainstream” market focuses on mass-produced lightweight aluminum fixtures, prioritizing rapid installation and standardized aesthetics. In contrast, the “high-end” market occupied by AHL Group's Corten steel lighting serves customized architectural projects—where the material itself constitutes a design statement. The pricing benchmark for premium lighting products lies in their performance under extreme climates and their enduring structural integrity over time.

Why Material Choice Creates Significant Cost Differences

Material selection is the core variable influencing a luminaire manufacturer's suggested retail price (MSRP). As a special alloy, weathering steel operates under entirely different price fluctuation mechanisms than commodity aluminum. This choice is not merely aesthetic; it represents a decision between two materials: aluminum that adapts to its environment, and weathering steel that elevates itself through its environment.

Breaking Down the Cost Drivers

To justify a higher investment, one must understand the four primary drivers of production costs in the lighting manufacturing industry.

Driver 1: Material Sourcing and Scarcity

The journey of an outdoor light begins at the mill. The disparity in raw material costs is the first major hurdle for budget-conscious designers.

Procurement of Certified A588 Corten Steel vs. Standard Aluminum

AHL Group utilizes ASTM A588 weathering steel, a high-strength, low-alloy structural steel. Unlike standard low-carbon steel or recycled commodity aluminum, A588 requires chemical composition certification to ensure proper formation of its protective rust layer. Aluminum resources are globally abundant with high recycling rates, keeping raw material costs low. Certified weathering steel, however, is a specialty product with limited global manufacturers, resulting in higher procurement costs and stricter quality control requirements.

Driver 2: Production Scale and Methods

The “method of manufacture” for lighting fixtures impacts their price as significantly as the materials themselves.

Limited-Batch Craftsmanship vs. Mass Casting

Aluminum fixtures are typically produced using high-pressure die casting. While initial mold costs are substantial, unit costs decrease significantly with increased production volume. Corten steel garden lights, however, demand highly skilled manufacturing due to their hardness and structural properties. At AHL Group, this involves precision CNC laser cutting, TIG/MIG welding using specialized weathering steel electrodes, and meticulous hand finishing. This labor-intensive process ensures each fixture is a robust engineering masterpiece, not an assembly-line shell.

Driver 3: The "Built-In" Finish

Surface treatment processes often represent the “hidden” costs in lighting manufacturing.

No Painting or Coating Needed vs. Multi-Step Finishing Processes

Aluminum luminaires undergo multiple surface treatment steps: cleaning, pretreatment, powder coating, and baking/curing. Failure at any stage causes coating failure. Weathering steel, however, features “built-in” surface protection—its protective layer forms through chemical reactions with the atmosphere. While eliminating coating costs, these expenses are instead embedded in the alloy itself. For customers, this means AHL Group luminaires never require “recoating,” whereas aluminum fixtures typically show surface degradation within 5-7 years.

Driver 4: Structural and Handling Demands

The physical weight of a product impacts every stage from manufacturing to final installation.

Heavy, Robust Fixtures vs. Light, Simple Assemblies

Standard Corten steel lights can weigh 3 to 5 times more than their aluminum counterparts. This necessitates heavy-duty internal supports, thicker mounting plates, and more robust electrical enclosures. In factory production, this translates to higher energy consumption during cutting and welding processes; in the logistics chain, it means increased transportation costs. For end-users, however, this construction withstands accidental impacts, high winds, and vandalism—factors that could overwhelm thin-walled aluminum fixtures.

The Long-Term Investment Angle

The data shows that savvy buyers look for "Total Cost of Ownership" rather than just "Purchase Price."

Corten Steel: Lifetime Purchase, Minimal Maintenance

AHL Group's Corten steel outdoor lighting boasts a lifespan exceeding 50 years. Maintenance requires only an annual rinse to remove salt deposits. When amortized over 30 years, a $300 Corten light proves far more economical than aluminum alternatives—which necessitate replacement or professional refurbishment every decade.

Aluminum: Surface Degradation and Replacement Risks

In coastal or high-pollution environments, aluminum is prone to “filiform corrosion” or powder coating oxidation. Once the coating is compromised, the fixture loses its aesthetic value. This often results in a “disposable” lighting cycle—where entire fixtures are replaced due to surface damage.

Resale Value vs. Property Appreciation

Architectural-grade materials like Corten steel tangibly enhance a property's “curb appeal.” High-end buyers perceive weathering steel as a premium material, often associating it with bespoke architectural design. This appreciation effect far surpasses that of standard aluminum fixtures, significantly boosting the overall valuation of landscape projects.

Side-by-Side Value Assessment

Let’s look at the "Dollar-for-Dollar" reality of a lighting purchase.

Comparing a $300 Corten Steel Light to a $100 Aluminum Light

At first glance, the $300 fixture seems expensive. But you're paying not just for the price tag, but for density, durability, and artistic value. The $100 aluminum fixture is merely a commodity, while the $300 fixture is a permanent installation. At AHL Group, we ensure this $200 difference is reflected in masterful welding techniques, substantial steel thickness, and precision laser-cut holes.

Comparing the True Value of Different Materials

• Aluminum Fixtures: Lightweight, easy installation, instant color selection, low initial cost.

• Corten Steel Lamps: Ultimate durability, organic aesthetic that evolves, high wind and impact resistance, zero-maintenance surface treatment.

Emotional and Aesthetic Rewards

Lighting is about ambiance. The warm earth tones emitted by rusted Corten lighting establish a connection with nature that cool-toned powder-coated aluminum fixtures cannot match. Its “emotional reward” stems from witnessing the light transform in color over time, ultimately blending into the landscape rather than standing out as an alien element.

Expert Recommendations

How do the pros decide? Here is the industry consensus.

How Landscape Architects Specify Premium Materials

Professional designers often specify weathering steel for “core areas”—entrances, focal pathways, and public gathering points—where lighting creates visual focal points. They view this as a way to establish the project's tone through specific material selections.

When to Mix Materials in a Project

Not every area requires premium materials. A common strategy is to use AHL Group's weathering steel bollard lights along main walkways, while employing more economical concealed aluminum spotlights for uplighting trees and shrubs—since the fixtures themselves remain invisible.

How to Assess the Quality of Both Materials

For weathering steel, examine whether welds are smooth and continuous, and whether the surface is uniform (even before rusting occurs). For aluminum, check the “mil thickness” of the powder coating and ensure the housing is die-cast rather than thin spun metal.

Navigating Your Purchase

Before committing your budget, ask the right questions.

Questions to Confirm Before Decision-Making

1. Is the steel A588 certified, or merely “rust-proof coated”?

2. What is the wall thickness of the luminaire? (AHL Group standard is 3mm or above)

3. What is the IP protection rating for the internal electronic components?

How to Evaluate Quality Across Different Price Ranges

High-quality Corten steel landscape lights should convey an “over-engineered” feel. If they appear flimsy or structurally loose, they are likely not genuine weathering steel. The quality of aluminum luminaires is reflected in the sealing gaskets and the heat dissipation performance of the LED modules.

Frequently Asked Questions About Corten Lights

Q: Can Aluminium Achieve the Corten Steel Effect?

Only through “imitation” coatings. While passable from a distance, it lacks Corten steel's distinctive textured appearance, deep dimensionality, and self-healing scratch resistance.

Q: Are There Inexpensive Corten Steel Lamps? (Are They Worth Buying?)

So-called “inexpensive” Corten steel is typically just ordinary carbon steel. It will rust, but will eventually rust through, leading to structural failure and unsightly stains. Only authentic weathering steel from reputable manufacturers like AHL Group ensures rust remains confined to the surface.

Q: Does Price Differentiation Reflect Warranty Duration?

Typically yes. Premium Corten steel lights often offer extended structural warranties, as manufacturers recognize this material is virtually indestructible in most environments.

Conclusion: Prioritize Quality Over Price

Ultimately, choosing weathering steel or aluminum lighting hinges on the project's vision. For temporary solutions or budget-driven quick fixes, aluminum remains a practical choice. However, when crafting enduring architectural masterpieces whose beauty deepens over time, the price difference of weathering steel isn't a “cost”—it's an investment in quality. AHL Group delivers heavy-duty lighting solutions that bridge functionality with timeless artistry.

Contact AHL Group today for technical consultation on premium outdoor lighting projects or bulk pricing.