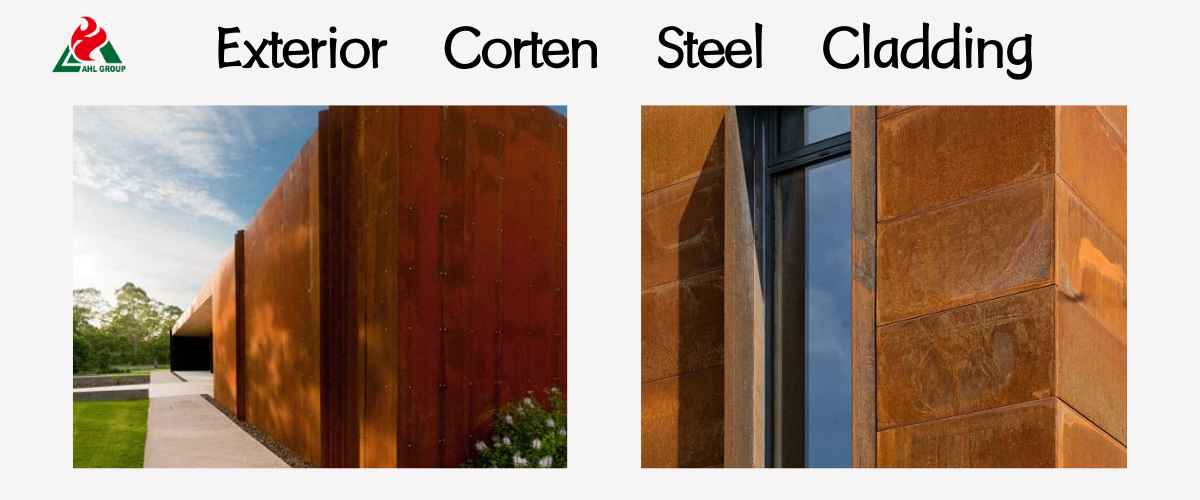

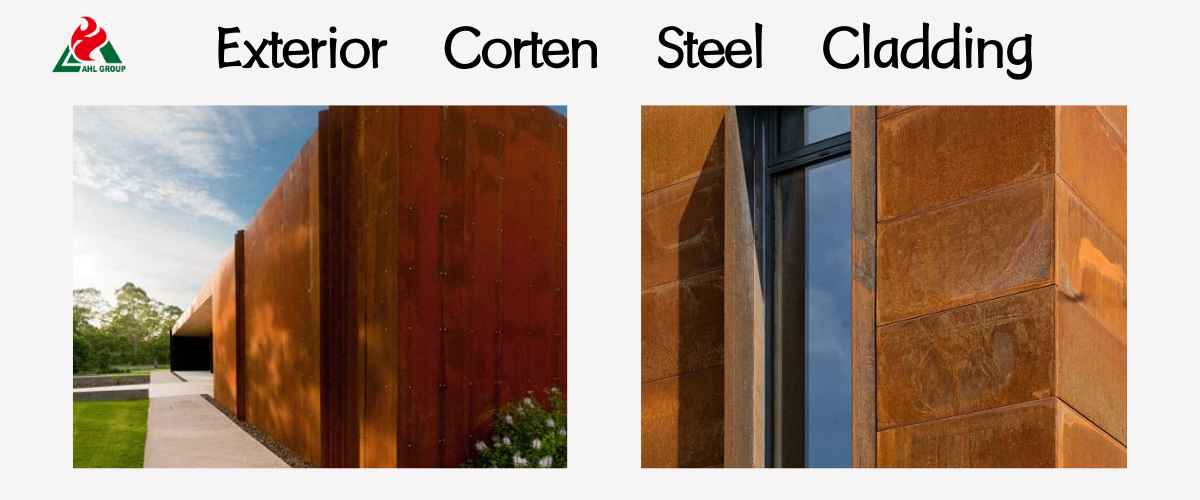

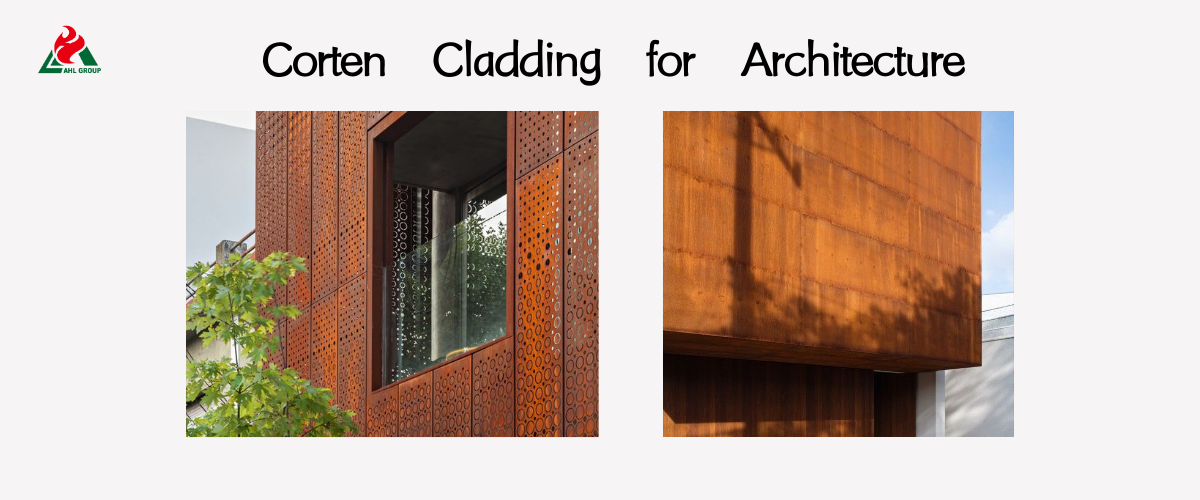

Corten steel cladding panels rank among the most expressive and durable materials for building facades. Their popularity stems not only from exceptional structural strength and maintenance-free longevity, but crucially from their unique and evolving color system. For architects, builders, and designers selecting AHL Corten steel cladding panels, understanding the precise timeline and influencing factors of the patina's color evolution is crucial—it enables effective management of client expectations while achieving the desired final aesthetic outcome. This AHL Group guide comprehensively details the material's aesthetic transformation journey, empowering you to confidently predict and embrace the color metamorphosis of weathering steel in your projects.

Dynamic Characteristics of Corten Steel Cladding

Unlike painted or galvanized metals, weathering steel is a dynamic material whose appearance directly results from its interaction with the atmospheric environment.

Understanding the Dynamic Nature of Weathering Steel

Weathering steel is a special alloy steel containing elements such as copper, chromium, and nickel. When exposed to natural environments, its surface develops a dense protective layer of iron oxide (commonly known as patina). This gradual process involves complex chemical reactions, causing the material to undergo continuous color evolution during its initial months. This visual transformation—the color evolution of weathering steel—is tangible evidence of the ongoing formation of the protective layer beneath the surface, effectively preventing deeper corrosion.

Why Color Evolution is a Design Highlight, Not a Flaw

The shifting hues of AHL Corten steel panels represent a core, deliberately designed value. Successful Corten steel facades are highly prized for their ability to reflect the passage of time and the unique microclimate of their location. This dynamic, organic aesthetic sets it apart from static materials, making it a key reason designers choose Corten cladding for contemporary and industrial projects.

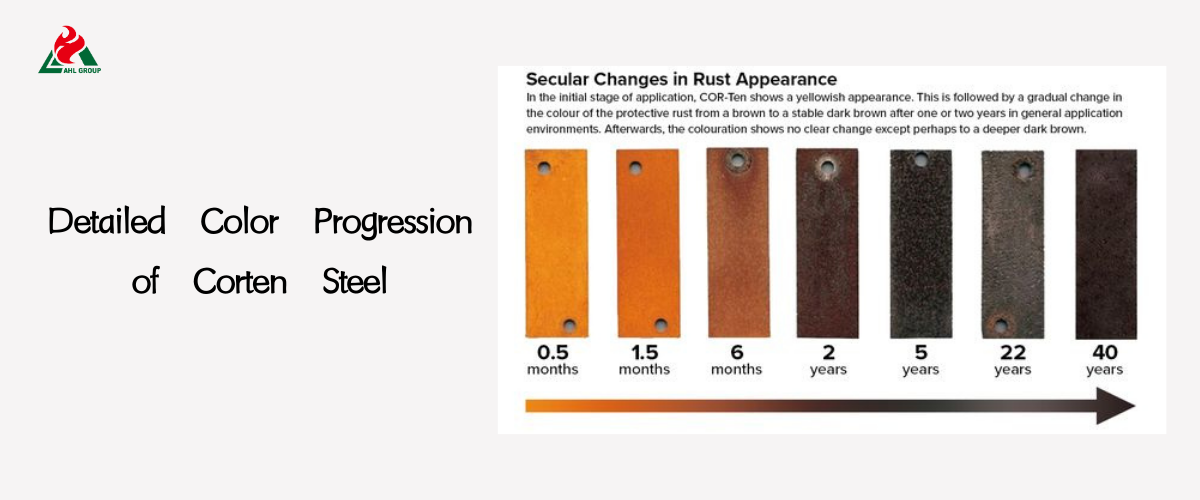

Detailed Color Progression Analysis

Under average humidity and rainfall conditions, the color change of Corten steel siding typically follows a predictable four-stage timeline. Understanding these stages is key to effective project management.

1. Initial Metal Stage (0-2 weeks)

Factory-finished Surface Characteristics

AHL weathering steel cladding exhibits a blue-gray or deep metallic appearance upon initial installation, depending on residual mill scale and anti-corrosion treatment. The surface is clean and smooth, without typical rust patina. Design Considerations: Handle with care during this phase, as oils from fingerprints can hinder uniform moisture adhesion, leading to uneven rust layer formation later.

2. Early Rust Layer Formation (2–8 weeks)

Bright Orange-Red Hue Emerges

Following initial exposure to moisture (rain or high humidity) and subsequent drying cycles, the standard iron oxide rusting process intensifies. A vivid, intense orange-red hue rapidly forms on the surface. The initial rust layer is porous and powdery, leading to characteristic rust runoff. This stage is marked by dramatic visual changes and the most significant staining of adjacent materials (e.g., concrete, stone). Managing rust runoff is critical during this phase.

3. Intermediate Stabilization Stage (2–12 months)

Color Changes to Deep Terracotta and Brownish-Red

As copper-chromium alloy elements begin reacting, the porous initial rust layer gradually transforms into a dense, adherent protective rust coating. Colors transition from bright orange to deeper terracotta or dark reddish-brown hues. Surfaces exhibit mottled, uneven visual effects with pronounced differences between high-moisture and low-moisture zones. As the protective layer bonds more tightly to the base steel, runoff significantly decreases, the ongoing corrosion rate slows, and the material gradually approaches an ideal stable state.

4. Final Mature Patina (12+ Months)

Deep Bronze Hue with Subtle Shade Variations

After approximately 12 to 18 months, the protective oxide layer is fully formed and largely stabilized. The color settles into a deep, velvety dark bronze, chocolate, or purple-brown hue. The surface texture becomes fine and dense with no flaking, offering the strongest deep-layer corrosion protection. At this stage, the material achieves zero-maintenance status, with its color exhibiting only slight periodic variations depending on dry or humid conditions. This represents the ultimate stable realm of protective aesthetics.

Factors That Influence Color Development

Although the timeline is generally predictable, three primary environmental variables determine the rate of color change and the final hue of Corten cladding.

Environmental Conditions: Rainwater, Sunlight, and Pollution

► Humidity: A key factor in initiating and sustaining the corrosion cycle. Areas with high rainfall or humidity accelerate this process.

► Dryness: Equally important. Steel must be completely dry to form a dense protective layer. Persistent dampness without drying leads to unstable, non-protective rust.

► Pollution: Industrial zones or urban areas with high traffic volume often contain elevated atmospheric sulfur levels, resulting in deeper, more intense bronze-colored rust layers compared to rural environments.

Geographic Location and Climate

Rust layer formation proceeds significantly slower in cold, arid climates than in warm, humid, or coastal regions (potentially delayed by several years). The density and chemical composition of air and rainfall directly influence the final hue of weathering steel facades.

Installation Orientation and Water Flow

The orientation of Corten metal cladding significantly impacts uniformity. Vertical panels continuously exposed to sheet water flow (e.g., from copings or parapets) exhibit superior rusting speed and uniformity compared to shaded or horizontal areas. Deeper, more pronounced rust patterns often develop where water pools or drips persistently.

Managing Color Consistency in Design

Controlling and pre-treating the environment through architectural design is the optimal approach to ensure AHL Corten siding panels achieve the most stable and ideal patina.

Promoting Uniform Coloration Techniques

► Pre-weathering/Accelerated Treatment: To achieve immediate color consistency and control initial bleeding, steel may undergo chemical pre-treatment or accelerated weathering before installation.

► Degreasing: Ensure all AHL panels are thoroughly cleaned before exposure, free of rolling oils or handling grease residues, to achieve uniform water absorption across the entire surface.

► Wetting Treatment: In arid climates, manually spraying metal panels within weeks of installation significantly accelerates stabilization.

Addressing Color Variation and Streaking

Streaking and flow lines are common and unavoidable during the initial months. While often regarded as a mark of authenticity, meticulous design details can minimize these effects by directing water away from visible facades—particularly near light-colored ground materials or adjacent finishes.

Architectural Strategies Embracing Change

The most successful Corten steel cladding projects transform the material's dynamic characteristics into a core design asset. Selecting high-quality, stable materials like AHL weathering steel and embracing subtle variations across large surfaces ensures the final effect achieves an organic, authentic texture rather than a mechanically rigid appearance.

Long-Term Color Expectations

Stable Condition of Patina After 12-18 Months

Once the dense protective patina has fully stabilized, its rate of change will significantly slow. The deep bronze hue remains constant, with only subtle variations arising from recent humidity or accumulated grime. The protective layer is now fully formed, providing the structure with maximum corrosion resistance characteristic of weathering steel.

Appearance Maintenance Guide

Structural protection requires virtually no maintenance. For cosmetic upkeep, gently rinse with clean water to remove surface grime or bird droppings that may temporarily alter color. Never use abrasive cleaners or brushes, as these can damage the protective oxide layer.

The Ultimate Gift: Unique Weathering Aesthetics

The mature patina that ultimately forms carries the cumulative history of the building—this enduring façade becomes a truly unique presence within its region. This self-healing weathering aesthetic makes AHL weathering cladding wall a premier architectural finish with unparalleled qualities.

Frequently Asked Questions About Corten Cladding

Q: Can You Predict the Final Color?

You can anticipate the color range (dark bronze/terracotta), but the exact final hue cannot be determined. The final color is like a unique fingerprint, shaped by the local microclimate (humidity, acidity of rainfall, pollutants, and salt content).

Q: Will the Color Change Stop?

Dramatic color shifts will cease after an initial 12-18 month stabilization period. However, the steel retains its “living” quality—colors may subtly deepen or shift slightly with surface moisture levels, while the overall hue remains stable.

Q: How Does Maintenance Affect Color?

Chemical treatments are strictly prohibited on weathering steel surfaces. Rinsing with clean water removes surface dust and restores the original appearance without altering the protective rust layer’s chemical properties.

Conclusion: Enhancing Architectural Aesthetics with Corten Steel Cladding

The artistic appeal of AHL weathering cladding panel lies in its transformation from a raw metallic surface into a deep, complex bronze patina. By understanding its four-stage color evolution mechanism and environmental factors, architects and designers can skillfully utilize this dynamic weathering steel to create durable, maintenance-free, and visually striking building facades that truly reflect the essence of unique environments.