Corten steel screens enhance the aesthetic appeal of outdoor spaces, but their weight requires robust support structures. As Chief Structural Engineer at AHL Group, I have witnessed installation failures due to improper column selection. This guide, informed by a decade of practical experience, provides load-bearing calculations, minimum column specifications, and installation methods. Whether for small dividers or large windbreaks, mastering these principles ensures your Corten screens remain durable and long-lasting.

The density and thickness of weathering steel make it significantly heavier than alternative shielding materials such as wood, composite materials, or aluminum. This inherent weight enhances its stability while also presenting specific installation requirements.

Weathering steel has a density of 7.85 grams per cubic centimeter, approximately three times that of aluminum and 50% higher than most hardwoods. This material density provides the mass required for wind resistance and structural rigidity, necessitating proportionally designed support systems. Unlike lightweight alternatives that may flex in the wind, AHL Group's weathering steel screens maintain precise alignment through their mass and engineered precision, transforming weight into a functional advantage rather than merely an installation consideration.

The basic formula for calculating weathering steel weight is straightforward:

► Metric: Area (m²) × Thickness (mm) × 7.85 = Weight (kg)

► Imperial: Area (ft²) × Thickness (inches) × 40.8 = Weight (lbs)

Example: A 1m² panel of 3mm-thick weathering steel weighs approximately 23.55kg (1 × 3 × 7.85), while a 10ft² panel of 1/8-inch (3.175mm) thick weathering steel weighs approximately 13lbs (10 × 0.125 × 40.8). AHL Group's Engineering Department provides precise weight specifications for each design, but these calculations assist planners in anticipating structural requirements during early design phases.

Accurate assessment of weight coefficients is critical for safe installation and long-term stability. This analysis involves more than simple accumulation; it requires examining how weight distribution, screen panel thickness, and environmental forces interact to determine structural requirements. Understanding these variables enables rational planning, ensuring your weathering steel screens serve both aesthetic functions and endure as durable architectural components.

AHL Group categorizes Corten panels by both aesthetic and structural characteristics:

► Lightweight panels (2-3 mm / 0.079-0.118 in): 15.7-23.6 kg/m² (3.2-4.8 lb/ft²)

° Applications: Interior decorative screens, small courtyard landscaping

° AHL Group recommendation: Maximum height 1.2 meters without additional support

► Medium panels (3-5 mm / 0.118-0.197 inches): 23.6-39.3 kg/m² (4.8-8.0 lb/ft²)

° Applications: Standard privacy screens, most residential installations

° AHL Group's most common specification: Balances durability with manageable weight

► Heavy-duty panels (5 mm and above): 39.3+ kg/m² (8.0+ lb/ft²)

° Applications: Commercial installations, high-wind areas, load-bearing screens

° Requires AHL Group engineering support: Panels exceeding 5 mm thickness

To translate theory into practical planning, specific case studies help illustrate the physical requirements of Corten garden screens. These real-world scenarios convert weight calculations into actionable considerations involving handling, transportation, and support system design. By analyzing specific dimensions and their corresponding weights, installers and owners can better address the logistical challenges associated with using large Corten steel panels.

► 1m × 2m panel, 3mm thickness: Approximately 47kg (104 lbs)

► 4ft × 8ft panel, 1/4-inch thickness: Approximately 327 lbs (148 kg)

► 1.5m × 3m panel, 4mm thick: approx. 141kg (311 lbs)

AHL Group installation teams determine staffing and equipment requirements based on these calculations. Standard 4×8-foot medium-thickness screen panels typically require at least two experienced installers working with professional lifting equipment, underscoring the necessity of professional installation.

The intricate patterns of Corten metal screens create a visually stunning effect while significantly influencing their structural properties. Laser cutting removes material, altering not only weight but also wind load dynamics and stress distribution patterns. Understanding this relationship between aesthetics and engineering is crucial for selecting appropriate support systems that accommodate both the reduced mass of patterned panels and their potentially increased aerodynamic effects.

AHL Group's precision laser cutting technology creates intricate patterns by removing material, with weight reduction effects varying significantly by design complexity:

► Simple Patterns (≤20% material removal): 5-10% weight reduction

► Medium Patterns (20-40% material removal): 15-25% weight reduction

► Complex Patterns (40-60% material removal): 30-45% weight reduction

However, pattern density impacts wind load differently than simple weight reduction. More open patterns reduce aerodynamic drag but may require additional support to resist torsional forces. AHL Group's structural analysis for each design evaluates both weight and wind load characteristics—certain complex patterns, despite being lighter overall, may require sturdier columns due to enhanced aerodynamic effects.

The term “special posts” specifically refers to engineered support systems designed to address the unique combination of static weight, wind loads, and bending moments generated by Corten outdoor screens. These are not simply reinforced versions of standard fence posts, but rather structural components tailored to meet the specific challenges posed by large metal panels. Understanding their “specialized nature” helps clarify why ordinary support structures inevitably fail, providing a sound rationale for investing in professional structural components.

Ordinary fence posts typically fail under Corten's weight and wind-loading demands. AHL Group's "engineered post systems" differ in three critical aspects:

1. Material Strength: Standard fence posts typically use thin-walled hollow steel tubes. However, AHL Group mandates that garden screen posts exceeding 1.5 meters in height must employ square structural steel tubes or solid steel tubes with a minimum wall thickness of 5 millimeters.

2. Section Dimensions: Minimum dimensions increase with screen panel size:

° Barrier height ≤ 1.5 meters: Minimum 80×80 mm (3×3 inches)

° Barrier height 1.5–2.5 meters: Minimum 100×100 mm (4×4 inches)

° Barrier height > 2.5 meters: 120×120 mm (5×5 inches) or larger, customized per project requirements

3. Embedment Depth Requirements: Follow the “one-third rule” for freestanding structures. Embedment depth must equal or exceed one-third of the exposed height, with an absolute minimum of 600 mm (24 inches) regardless of height. AHL Group mandates all permanent installations reach frost depth plus 300 mm (12 inches).

Establishing minimum specifications for columns provides clear engineering benchmarks for safe installation. These specifications account for material strength, cross-sectional dimensions, wall thickness, and corrosion protection measures to ensure columns can withstand both instantaneous static loads and long-term environmental stresses. These minimum requirements serve as a starting point and may need reinforcement based on specific site conditions, panel dimensions, and exposure factors.

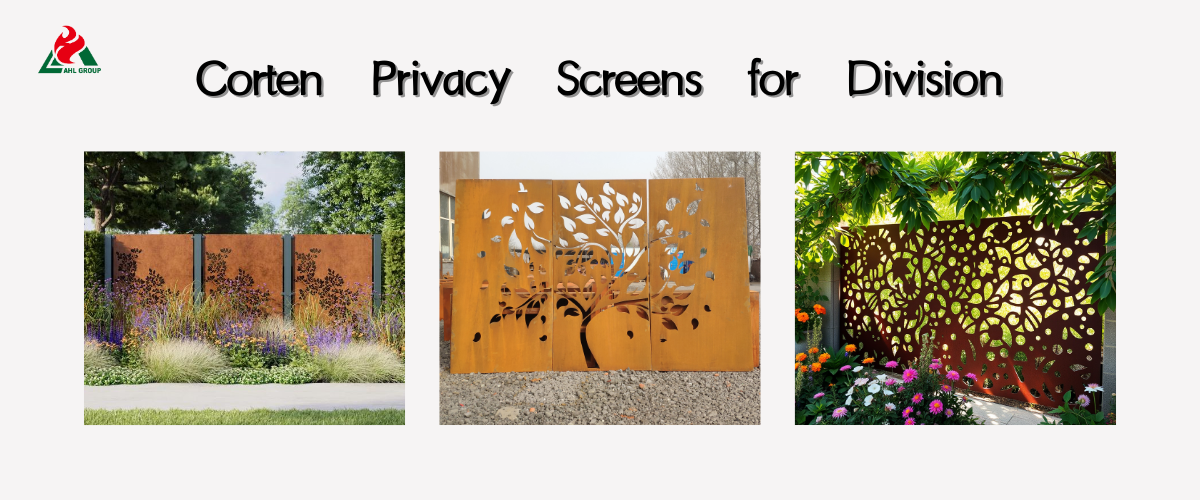

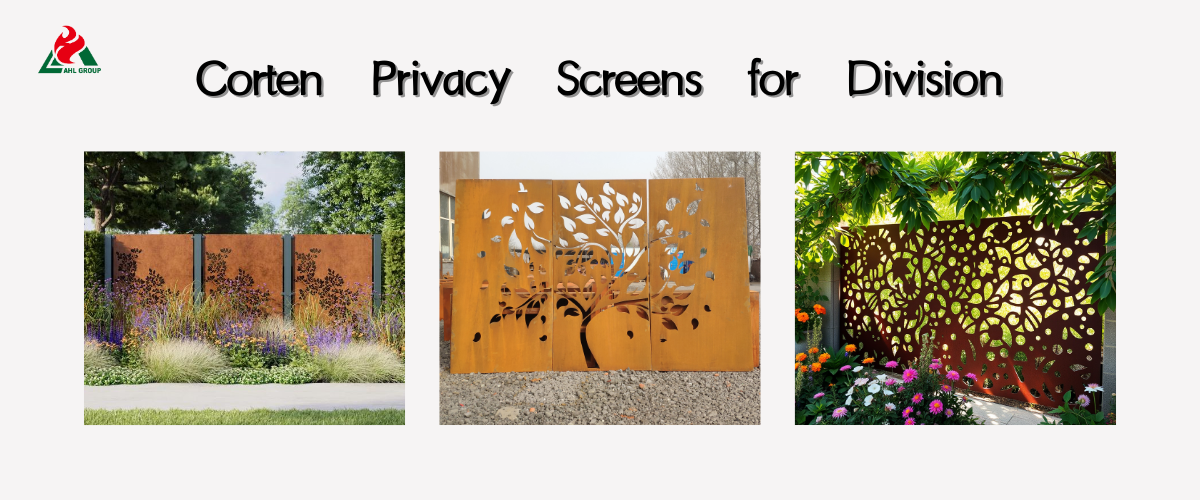

Freestanding screens require columns specifically designed for cantilever loads:

► Material: Hot-dip galvanized structural steel or weathering steel cladding

► Foundation preparation: Concrete base diameter = 3×column width

► Reinforcement measures: Screens over 2m in height require #4 rebar cages embedded in concrete

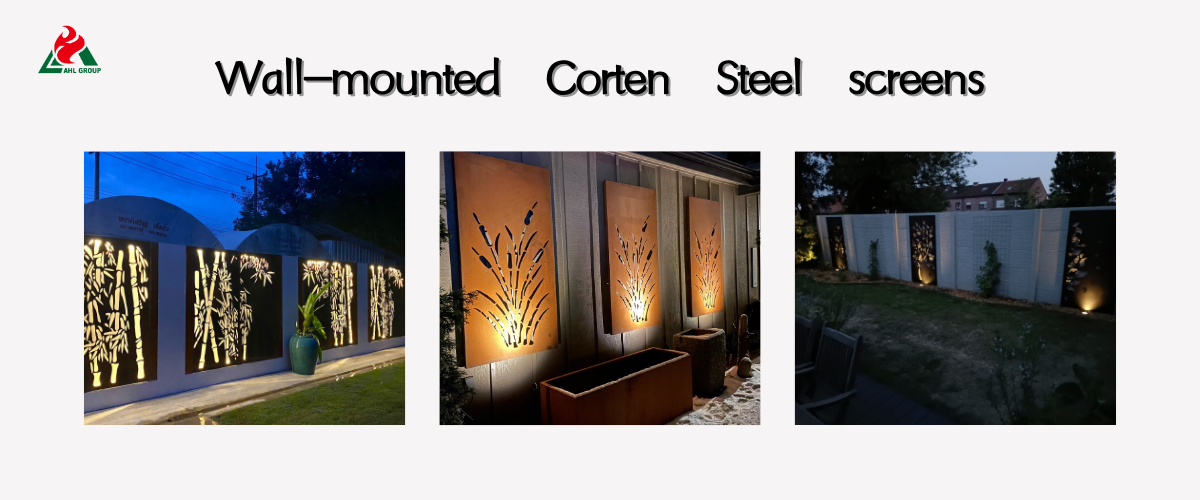

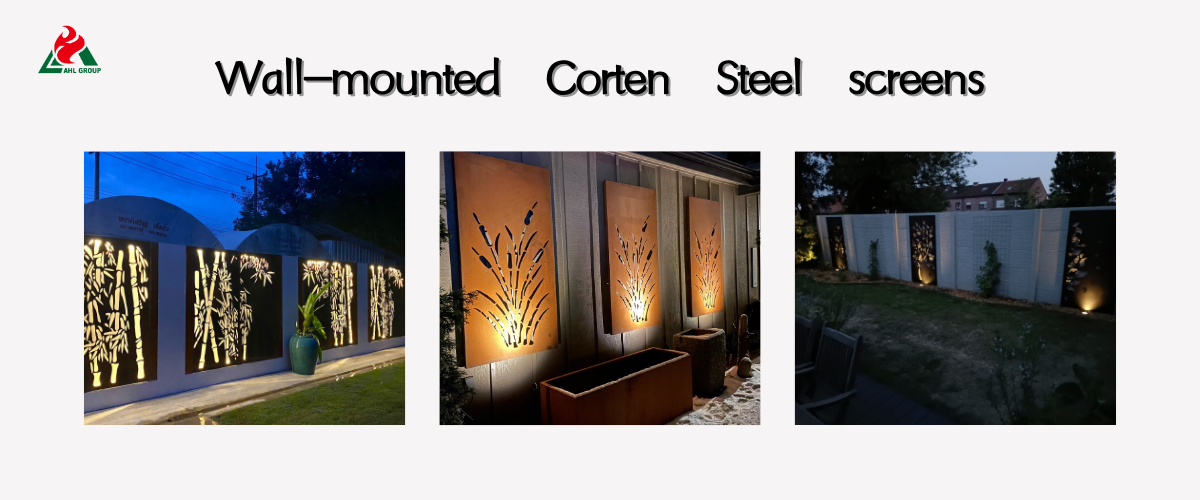

Wall-mounted screens utilize a different load transfer method:

► Connection points: Minimum 6mm thick steel mounting plates

► Wall anchoring: Bolted to structural members, not merely fixed to exterior wall panels

► Spacing: Maximum 1.2m spacing for 3mm panels; maximum 1.8m spacing for 5mm and thicker panels

AHL Group's technical specification sheets provide precise requirements for each panel design and dimension. Wall-mounted systems require a professional structural assessment of existing walls.

When traditional pile foundation systems prove difficult to implement due to site conditions, design preferences, or structural constraints, alternative support solutions offer innovative engineering alternatives. These methods—including concrete bases, gabion bases, and monolithic frames—distribute weight and resist external forces through different mechanisms while potentially enhancing aesthetic integration with the surrounding landscape.

When traditional posts are unsuitable, AHL Group offers alternative solutions:

► Concrete Base: Cast-in-place concrete base conceals the support structure while providing load-bearing capacity. Minimum dimensions: 300×300 mm (12×12 inches) base, extending 150 mm (6 inches) above ground level for moisture protection.

► Gabion Base: Metal mesh cages filled with stone, combining structural support with aesthetic integration. AHL Group gabion specifications: Minimum dimensions 400×400×600 mm (16×16×24 inches) for screens under 2 meters.

► Integrated Frame: Distributes loads across multiple support points via a steel structure. Particularly suitable for large AHL screen systems where any single dimension exceeds 3 meters.

Corten garden screens serve diverse purposes across various environments, each presenting unique structural challenges. This scenario guide translates engineering principles into practical specifications for common installation types, providing clear parameters for column dimensions, foundation requirements, and additional support based on screen height, location, and exposure conditions.

► Panel Thickness: 3mm weathering steel recommended

► Column Specifications: 80×80mm square HSS steel, 3mm wall thickness

► Foundation Requirements: 300mm diameter concrete foundation, 600mm depth

► Column Spacing: Maximum spacing 1.5m

► AHL Group Product Match: Urban Series Low Screen

► Panel Thickness: 4-5mm weathering steel panel required

► Column Specifications: 120×120mm square high-strength steel, 5mm wall thickness

► Foundation Requirements: 450mm diameter concrete foundation, depth ≥900mm (below frost line)

► Additional Support: Cross bracing or anchor piles recommended

► AHL Group Matching Product: WindMaster Commercial Series

► Structural Verification: Must be provided by a licensed engineer

► Installation Method: Bolted to structural supports through roof panels

► Weight Distribution: Minimum load distribution plate dimensions: 150×150×6 mm

► Wind Load: 150% of standard design requirements

► AHL Group Services: Custom engineering consultation required

Standard installation transforms engineering designs into physical structures through meticulous execution of ordered steps. This process begins with site assessment, followed sequentially by excavation, concrete pouring, column installation, and final panel fixing. Each stage requires specific techniques to ensure long-term stability and precise alignment. Adherence to a systematic approach prevents common installation errors that compromise structural integrity.

AHL Group's field-proven process begins with standardized excavation:

► Determine Frost Line Depth: Adhere to local building code minimum requirements (typically 600-1200 mm / 24-48 inches)

► Add Safety Margin: Include an additional 300 mm (12 inches) below the frost line depth

► Pore space requirement: Concrete volume must be 3 times the column width

► Base preparation: Install a 150 mm (6 in) compacted gravel layer for drainage

► Concrete Mix Design: Minimum 25MPa (3500psi), fiber reinforcement recommended

► Pouring Sequence: Pour to 1/3 depth first, position columns, calibrate verticality with support frames, then continue pouring

► Alignment Tools: Use a laser level and temporary cross-braced supports

► Curing Time: Curing for at least 7 days is required before installing panels in temperate climates

► AHL Group Recommendation: Embed threaded inserts in wet concrete for subsequent panel installation

► Isolation Measures: Use ultra-high molecular weight plastic or stainless steel spacers between weathering steel panels and columns to prevent electrochemical corrosion

► Fastener Specifications: Use A4 (316) stainless steel bolts with oversized holes to accommodate thermal expansion and contraction

► Connection Pattern: At least 4 connection points per side per panel

► Thermal Expansion Gap Spacing: Minimum 3mm gap between panels in temperate climates, minimum 5mm in extreme climates

► AHL Group Proprietary Bracket System: Allows seasonal displacement while maintaining alignment

In 95% of cases, existing posts cannot support the weight of weathering steel screens. Wooden posts are prone to rot where they contact steel, standard metal posts lack sufficient wall thickness, and concrete posts rarely feature adequate reinforcement measures. AHL Group's assessment plan only considers existing posts if the following conditions are met: (1) Service life < 5 years, (2) Original design load capacity, (3) Reinforcement feasibility. New construction posts are typically more cost-effective than retrofitting existing structures.

Following the one-third rule plus frost depth requirements, a 2-meter-high screen requires:

► Minimum burial depth: 0.66 meters (26 inches) to ensure structural stability

► Frost depth adjustment: Per local requirements (e.g., 0.9m/35 inches in the Chicago area)

► Total depth: 1.56m (5ft 1in) in frost zones, 0.8m (2ft 7in) in non-frost zones

► AHL Group Standard: Minimum 1.0m (39 inches) under all climatic conditions

Absolutely required. Standard wall anchors cannot support the weight of weathering steel or wind loads. Requirements include:

► Structural connection points: Studs, masonry, or concrete

► Fastener specifications: Through bolts with expansion plates; no rivets permitted

► Corrosion protection: Isolation treatment required between Cor-Ten steel and dissimilar metals

► Professional assessment: Screens exceeding 1 square meter must undergo evaluation

► AHL Group Wall-Mounting System: Includes thermal spacers and expansion-compatible brackets

Corten steel screens are not merely decorative elements; their weight is 4-8 times that of other materials, demanding precise engineering and robust support systems. AHL Group treats each screen as an integrated structural system comprising panels, support structures, and foundations—compromising any component jeopardizes the entire installation.

By adhering to these guidelines, consulting structural professionals, and complying with AHL standards, your weathering screen panel will remain durable and stable. Unlike temporary screens, a well-designed weathering steel installation should possess substantial presence, withstand seasonal changes, and maintain its aesthetic integrity for decades. Respecting the material's weight characteristics ensures enduring performance and visual appeal within the landscape.

Understanding the Weight of Corten Steel Screens

The density and thickness of weathering steel make it significantly heavier than alternative shielding materials such as wood, composite materials, or aluminum. This inherent weight enhances its stability while also presenting specific installation requirements.

Why Corten Steel is a Robust and Durable Material

Weathering steel has a density of 7.85 grams per cubic centimeter, approximately three times that of aluminum and 50% higher than most hardwoods. This material density provides the mass required for wind resistance and structural rigidity, necessitating proportionally designed support systems. Unlike lightweight alternatives that may flex in the wind, AHL Group's weathering steel screens maintain precise alignment through their mass and engineered precision, transforming weight into a functional advantage rather than merely an installation consideration.

Calculate Approximate Weight per Square Foot/Square Meter

The basic formula for calculating weathering steel weight is straightforward:

► Metric: Area (m²) × Thickness (mm) × 7.85 = Weight (kg)

► Imperial: Area (ft²) × Thickness (inches) × 40.8 = Weight (lbs)

Example: A 1m² panel of 3mm-thick weathering steel weighs approximately 23.55kg (1 × 3 × 7.85), while a 10ft² panel of 1/8-inch (3.175mm) thick weathering steel weighs approximately 13lbs (10 × 0.125 × 40.8). AHL Group's Engineering Department provides precise weight specifications for each design, but these calculations assist planners in anticipating structural requirements during early design phases.

Breaking Down the Weight Factor

Accurate assessment of weight coefficients is critical for safe installation and long-term stability. This analysis involves more than simple accumulation; it requires examining how weight distribution, screen panel thickness, and environmental forces interact to determine structural requirements. Understanding these variables enables rational planning, ensuring your weathering steel screens serve both aesthetic functions and endure as durable architectural components.

Weight Range by Thickness

AHL Group categorizes Corten panels by both aesthetic and structural characteristics:

Lightweight (2-3 mm), Medium (3-5 mm), Heavyweight (5 mm+) panels

► Lightweight panels (2-3 mm / 0.079-0.118 in): 15.7-23.6 kg/m² (3.2-4.8 lb/ft²)

° Applications: Interior decorative screens, small courtyard landscaping

° AHL Group recommendation: Maximum height 1.2 meters without additional support

► Medium panels (3-5 mm / 0.118-0.197 inches): 23.6-39.3 kg/m² (4.8-8.0 lb/ft²)

° Applications: Standard privacy screens, most residential installations

° AHL Group's most common specification: Balances durability with manageable weight

► Heavy-duty panels (5 mm and above): 39.3+ kg/m² (8.0+ lb/ft²)

° Applications: Commercial installations, high-wind areas, load-bearing screens

° Requires AHL Group engineering support: Panels exceeding 5 mm thickness

Real-World Weight Examples

To translate theory into practical planning, specific case studies help illustrate the physical requirements of Corten garden screens. These real-world scenarios convert weight calculations into actionable considerations involving handling, transportation, and support system design. By analyzing specific dimensions and their corresponding weights, installers and owners can better address the logistical challenges associated with using large Corten steel panels.

Estimated Weights for Common Screen Sizes

► 1m × 2m panel, 3mm thickness: Approximately 47kg (104 lbs)

► 4ft × 8ft panel, 1/4-inch thickness: Approximately 327 lbs (148 kg)

► 1.5m × 3m panel, 4mm thick: approx. 141kg (311 lbs)

AHL Group installation teams determine staffing and equipment requirements based on these calculations. Standard 4×8-foot medium-thickness screen panels typically require at least two experienced installers working with professional lifting equipment, underscoring the necessity of professional installation.

The Impact of Laser-Cut Patterns

The intricate patterns of Corten metal screens create a visually stunning effect while significantly influencing their structural properties. Laser cutting removes material, altering not only weight but also wind load dynamics and stress distribution patterns. Understanding this relationship between aesthetics and engineering is crucial for selecting appropriate support systems that accommodate both the reduced mass of patterned panels and their potentially increased aerodynamic effects.

How Complex Designs Achieve Overall Weight Reduction

AHL Group's precision laser cutting technology creates intricate patterns by removing material, with weight reduction effects varying significantly by design complexity:

► Simple Patterns (≤20% material removal): 5-10% weight reduction

► Medium Patterns (20-40% material removal): 15-25% weight reduction

► Complex Patterns (40-60% material removal): 30-45% weight reduction

However, pattern density impacts wind load differently than simple weight reduction. More open patterns reduce aerodynamic drag but may require additional support to resist torsional forces. AHL Group's structural analysis for each design evaluates both weight and wind load characteristics—certain complex patterns, despite being lighter overall, may require sturdier columns due to enhanced aerodynamic effects.

Demystifying "Special Posts"

The term “special posts” specifically refers to engineered support systems designed to address the unique combination of static weight, wind loads, and bending moments generated by Corten outdoor screens. These are not simply reinforced versions of standard fence posts, but rather structural components tailored to meet the specific challenges posed by large metal panels. Understanding their “specialized nature” helps clarify why ordinary support structures inevitably fail, providing a sound rationale for investing in professional structural components.

What Makes a Post "Special" for Corten?

Ordinary fence posts typically fail under Corten's weight and wind-loading demands. AHL Group's "engineered post systems" differ in three critical aspects:

Material Strength, Section Dimensions, and Burial Depth Requirements

1. Material Strength: Standard fence posts typically use thin-walled hollow steel tubes. However, AHL Group mandates that garden screen posts exceeding 1.5 meters in height must employ square structural steel tubes or solid steel tubes with a minimum wall thickness of 5 millimeters.

2. Section Dimensions: Minimum dimensions increase with screen panel size:

° Barrier height ≤ 1.5 meters: Minimum 80×80 mm (3×3 inches)

° Barrier height 1.5–2.5 meters: Minimum 100×100 mm (4×4 inches)

° Barrier height > 2.5 meters: 120×120 mm (5×5 inches) or larger, customized per project requirements

3. Embedment Depth Requirements: Follow the “one-third rule” for freestanding structures. Embedment depth must equal or exceed one-third of the exposed height, with an absolute minimum of 600 mm (24 inches) regardless of height. AHL Group mandates all permanent installations reach frost depth plus 300 mm (12 inches).

Minimum Post Specifications

Establishing minimum specifications for columns provides clear engineering benchmarks for safe installation. These specifications account for material strength, cross-sectional dimensions, wall thickness, and corrosion protection measures to ensure columns can withstand both instantaneous static loads and long-term environmental stresses. These minimum requirements serve as a starting point and may need reinforcement based on specific site conditions, panel dimensions, and exposure factors.

Comparison of Freestanding Screens and Wall-Mounted Screens

Freestanding screens require columns specifically designed for cantilever loads:

► Material: Hot-dip galvanized structural steel or weathering steel cladding

► Foundation preparation: Concrete base diameter = 3×column width

► Reinforcement measures: Screens over 2m in height require #4 rebar cages embedded in concrete

Wall-mounted screens utilize a different load transfer method:

► Connection points: Minimum 6mm thick steel mounting plates

► Wall anchoring: Bolted to structural members, not merely fixed to exterior wall panels

► Spacing: Maximum 1.2m spacing for 3mm panels; maximum 1.8m spacing for 5mm and thicker panels

AHL Group's technical specification sheets provide precise requirements for each panel design and dimension. Wall-mounted systems require a professional structural assessment of existing walls.

Alternative Support Methods

When traditional pile foundation systems prove difficult to implement due to site conditions, design preferences, or structural constraints, alternative support solutions offer innovative engineering alternatives. These methods—including concrete bases, gabion bases, and monolithic frames—distribute weight and resist external forces through different mechanisms while potentially enhancing aesthetic integration with the surrounding landscape.

Concrete Base, Gabion Base, and Integrated Frame

When traditional posts are unsuitable, AHL Group offers alternative solutions:

► Concrete Base: Cast-in-place concrete base conceals the support structure while providing load-bearing capacity. Minimum dimensions: 300×300 mm (12×12 inches) base, extending 150 mm (6 inches) above ground level for moisture protection.

► Gabion Base: Metal mesh cages filled with stone, combining structural support with aesthetic integration. AHL Group gabion specifications: Minimum dimensions 400×400×600 mm (16×16×24 inches) for screens under 2 meters.

► Integrated Frame: Distributes loads across multiple support points via a steel structure. Particularly suitable for large AHL screen systems where any single dimension exceeds 3 meters.

Specification Guidelines for Different Scenarios

Corten garden screens serve diverse purposes across various environments, each presenting unique structural challenges. This scenario guide translates engineering principles into practical specifications for common installation types, providing clear parameters for column dimensions, foundation requirements, and additional support based on screen height, location, and exposure conditions.

Scenario A: Small Low-Privacy Screen (Height < 1.5m)

► Panel Thickness: 3mm weathering steel recommended

► Column Specifications: 80×80mm square HSS steel, 3mm wall thickness

► Foundation Requirements: 300mm diameter concrete foundation, 600mm depth

► Column Spacing: Maximum spacing 1.5m

► AHL Group Product Match: Urban Series Low Screen

Scenario B: Large Windbreak Privacy Screen (Height > 2m)

► Panel Thickness: 4-5mm weathering steel panel required

► Column Specifications: 120×120mm square high-strength steel, 5mm wall thickness

► Foundation Requirements: 450mm diameter concrete foundation, depth ≥900mm (below frost line)

► Additional Support: Cross bracing or anchor piles recommended

► AHL Group Matching Product: WindMaster Commercial Series

Scenario C: Roof-Mounted or Elevated Screens

► Structural Verification: Must be provided by a licensed engineer

► Installation Method: Bolted to structural supports through roof panels

► Weight Distribution: Minimum load distribution plate dimensions: 150×150×6 mm

► Wind Load: 150% of standard design requirements

► AHL Group Services: Custom engineering consultation required

Step-by-Step Support System Installation

Standard installation transforms engineering designs into physical structures through meticulous execution of ordered steps. This process begins with site assessment, followed sequentially by excavation, concrete pouring, column installation, and final panel fixing. Each stage requires specific techniques to ensure long-term stability and precise alignment. Adherence to a systematic approach prevents common installation errors that compromise structural integrity.

Excavate Column Foundations to Frost Line Depth and Below

AHL Group's field-proven process begins with standardized excavation:

► Determine Frost Line Depth: Adhere to local building code minimum requirements (typically 600-1200 mm / 24-48 inches)

► Add Safety Margin: Include an additional 300 mm (12 inches) below the frost line depth

► Pore space requirement: Concrete volume must be 3 times the column width

► Base preparation: Install a 150 mm (6 in) compacted gravel layer for drainage

Mixing, Pouring, and Alignment of Concrete Foundations

► Concrete Mix Design: Minimum 25MPa (3500psi), fiber reinforcement recommended

► Pouring Sequence: Pour to 1/3 depth first, position columns, calibrate verticality with support frames, then continue pouring

► Alignment Tools: Use a laser level and temporary cross-braced supports

► Curing Time: Curing for at least 7 days is required before installing panels in temperate climates

► AHL Group Recommendation: Embed threaded inserts in wet concrete for subsequent panel installation

Corten Steel Panel Connection to Support Structure

► Isolation Measures: Use ultra-high molecular weight plastic or stainless steel spacers between weathering steel panels and columns to prevent electrochemical corrosion

► Fastener Specifications: Use A4 (316) stainless steel bolts with oversized holes to accommodate thermal expansion and contraction

► Connection Pattern: At least 4 connection points per side per panel

► Thermal Expansion Gap Spacing: Minimum 3mm gap between panels in temperate climates, minimum 5mm in extreme climates

► AHL Group Proprietary Bracket System: Allows seasonal displacement while maintaining alignment

Frequently Asked Questions About Corten Screens

Q: Can Existing Fence Posts Be Used? (Typically Not Feasible)

In 95% of cases, existing posts cannot support the weight of weathering steel screens. Wooden posts are prone to rot where they contact steel, standard metal posts lack sufficient wall thickness, and concrete posts rarely feature adequate reinforcement measures. AHL Group's assessment plan only considers existing posts if the following conditions are met: (1) Service life < 5 years, (2) Original design load capacity, (3) Reinforcement feasibility. New construction posts are typically more cost-effective than retrofitting existing structures.

Q: How Deep Should Posts Be for a 2m Tall Screen?

Following the one-third rule plus frost depth requirements, a 2-meter-high screen requires:

► Minimum burial depth: 0.66 meters (26 inches) to ensure structural stability

► Frost depth adjustment: Per local requirements (e.g., 0.9m/35 inches in the Chicago area)

► Total depth: 1.56m (5ft 1in) in frost zones, 0.8m (2ft 7in) in non-frost zones

► AHL Group Standard: Minimum 1.0m (39 inches) under all climatic conditions

Q: Do Wall-Mounted Screens Need "Special" Wall Fixings? (Yes)

Absolutely required. Standard wall anchors cannot support the weight of weathering steel or wind loads. Requirements include:

► Structural connection points: Studs, masonry, or concrete

► Fastener specifications: Through bolts with expansion plates; no rivets permitted

► Corrosion protection: Isolation treatment required between Cor-Ten steel and dissimilar metals

► Professional assessment: Screens exceeding 1 square meter must undergo evaluation

► AHL Group Wall-Mounting System: Includes thermal spacers and expansion-compatible brackets

Conclusion: Treating Corten Screens as a Permanent Architectural Element

Corten steel screens are not merely decorative elements; their weight is 4-8 times that of other materials, demanding precise engineering and robust support systems. AHL Group treats each screen as an integrated structural system comprising panels, support structures, and foundations—compromising any component jeopardizes the entire installation.

By adhering to these guidelines, consulting structural professionals, and complying with AHL standards, your weathering screen panel will remain durable and stable. Unlike temporary screens, a well-designed weathering steel installation should possess substantial presence, withstand seasonal changes, and maintain its aesthetic integrity for decades. Respecting the material's weight characteristics ensures enduring performance and visual appeal within the landscape.